Water paint composition

A technology for water-based coatings and compositions, applied in polyester coatings, starch derivative coatings, polyurea/polyurethane coatings, etc., can solve the problems of high production cost, less application, and reduced water resistance and other coating film properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

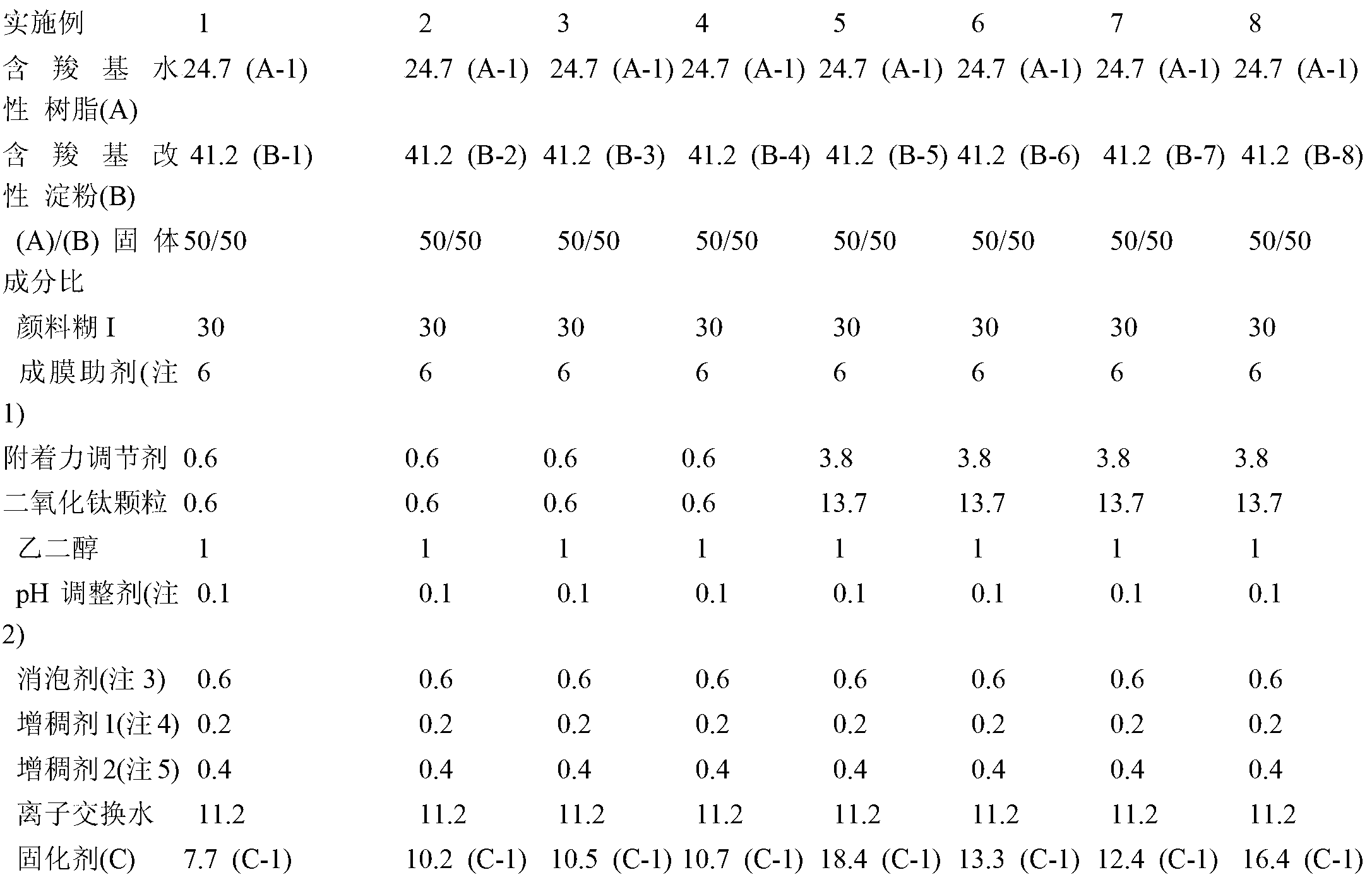

Examples

manufacture example 1

[0076] 34.5 parts of ion-exchanged water and 0.3 parts of an emulsifier (trade name "Pelex SS-H", manufactured by Kao Corporation, sodium alkyl diphenyl ether sulfonate) were charged into a device equipped with a dropping funnel, a thermometer, a nitrogen gas introduction tube, A detachable flask with a reflux condenser and a stirrer was heated to 80°C under a nitrogen atmosphere. After adding 0.6 parts of dodecyl mercaptan to a monomer mixture consisting of 15 parts of styrene, 41.1 parts of 2-ethylhexyl acrylate, 42.0 parts of methyl methacrylate and 1.9 parts of acrylic acid, add 1.2 parts of "Pelex SS-H" was melt|dissolved in the emulsifier aqueous solution obtained by 50 parts of ion-exchange water, it emulsified using the mixer, and the pre-emulsion was obtained. Dissolve 0.3 parts of ammonium persulfate in 13 parts of ion-exchanged water to obtain an aqueous initiator solution. Using different dropping funnels, the above-mentioned pre-emulsion and aqueous initiator solu...

manufacture example 2

[0078] In Production Example 1, a monomer mixture composed of 15 parts of styrene, 41.1 parts of 2-ethylhexyl acrylate, 33.6 parts of methyl methacrylate and 10.3 parts of acrylic acid was used. The same operation as Example 1 was used to prepare a carboxyl-containing aqueous acrylic resin emulsion (A-2) with an acid value of 80 mgKOH / g, a glass transition temperature of 5° C., and a solid content of 50%.

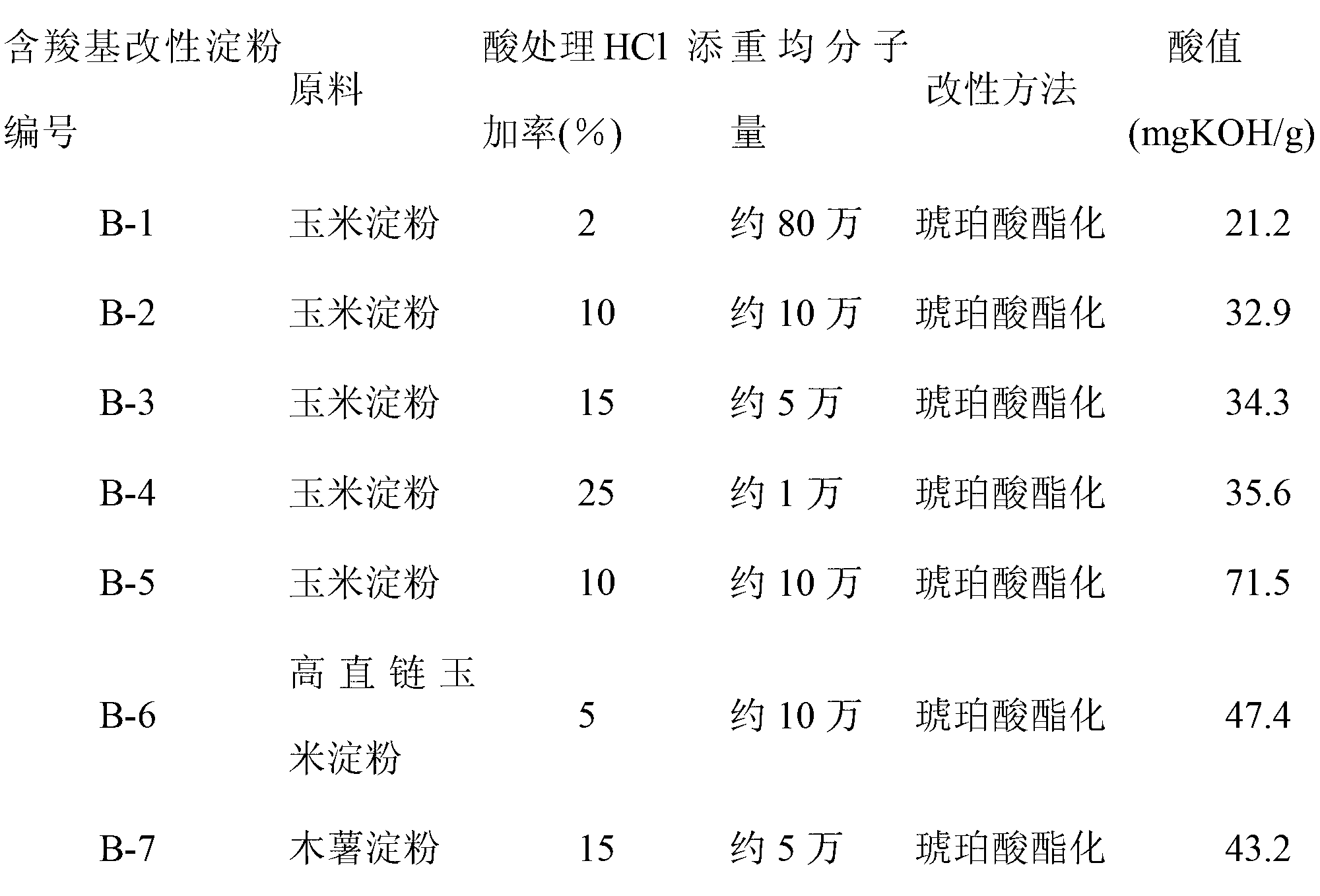

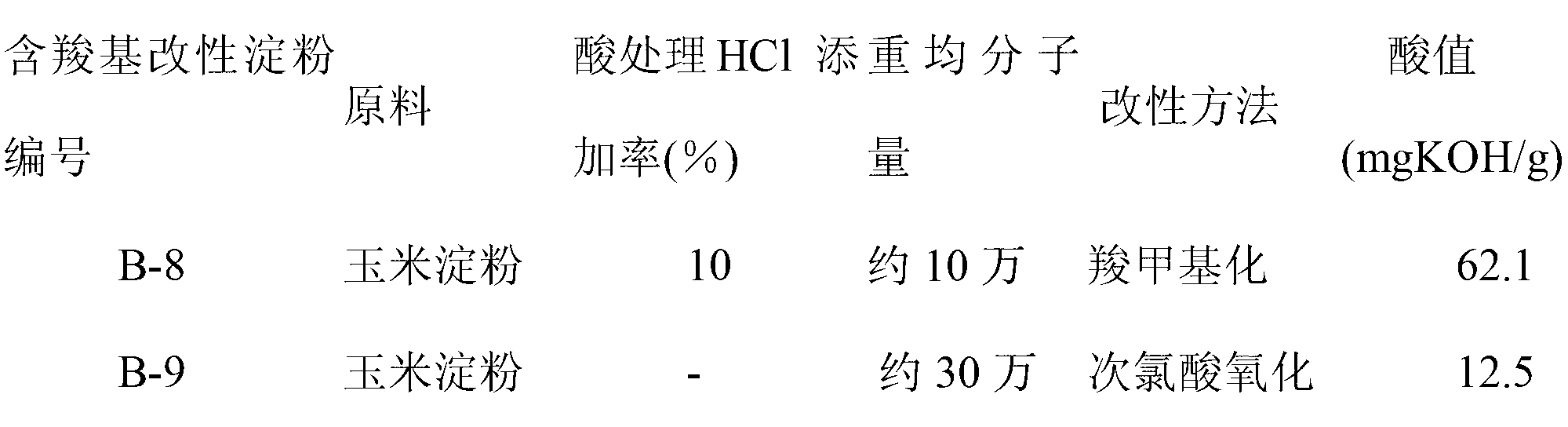

[0079] Modification of carboxy-containing modified starch (B)

[0080] Adjustment of starch molecular weight

[0081]According to the following method, the raw material starch used for the synthesis|combination of modified starch is acid-treated as needed, and molecular weight adjustment is performed. Suspend the raw starch in water to prepare a slurry with a concentration of 40%. This was kept at about 50° C., and a predetermined amount of hydrochloric acid was added to the above slurry while stirring. After the addition of the above-mentioned hydrochloric acid was star...

manufacture example 3

[0083] Suspend acid-treated cornstarch with a weight-average molecular weight of about 800,000 in water to prepare a 35% slurry. The slurry was heated while stirring in a thermostat set at 30° C., and the pH was adjusted to 8.5 using sodium hydroxide. While maintaining the pH at 8.0 to 8.5, succinic anhydride was added in an amount of 6% to the above-mentioned cornstarch over about 30 minutes, and after the addition was completed, the reaction was continued for 5 minutes. Then, use hydrochloric acid to neutralize the reaction solution, and then suspend it in a concentration of 50% ethanol solution, dehydrate, wash, and dry, thus making carboxyl-containing modified starch (B- 1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com