Oxygen-enriched combustion and solid oxide fuel cell hybrid power generating system

A solid oxide and fuel cell technology, applied in the direction of fuel cells, fuel cell applications, fuel cell additives, etc., can solve the problems of turbine combustion loss, system power generation efficiency to be improved, etc., to protect the environment, save energy, and reduce pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

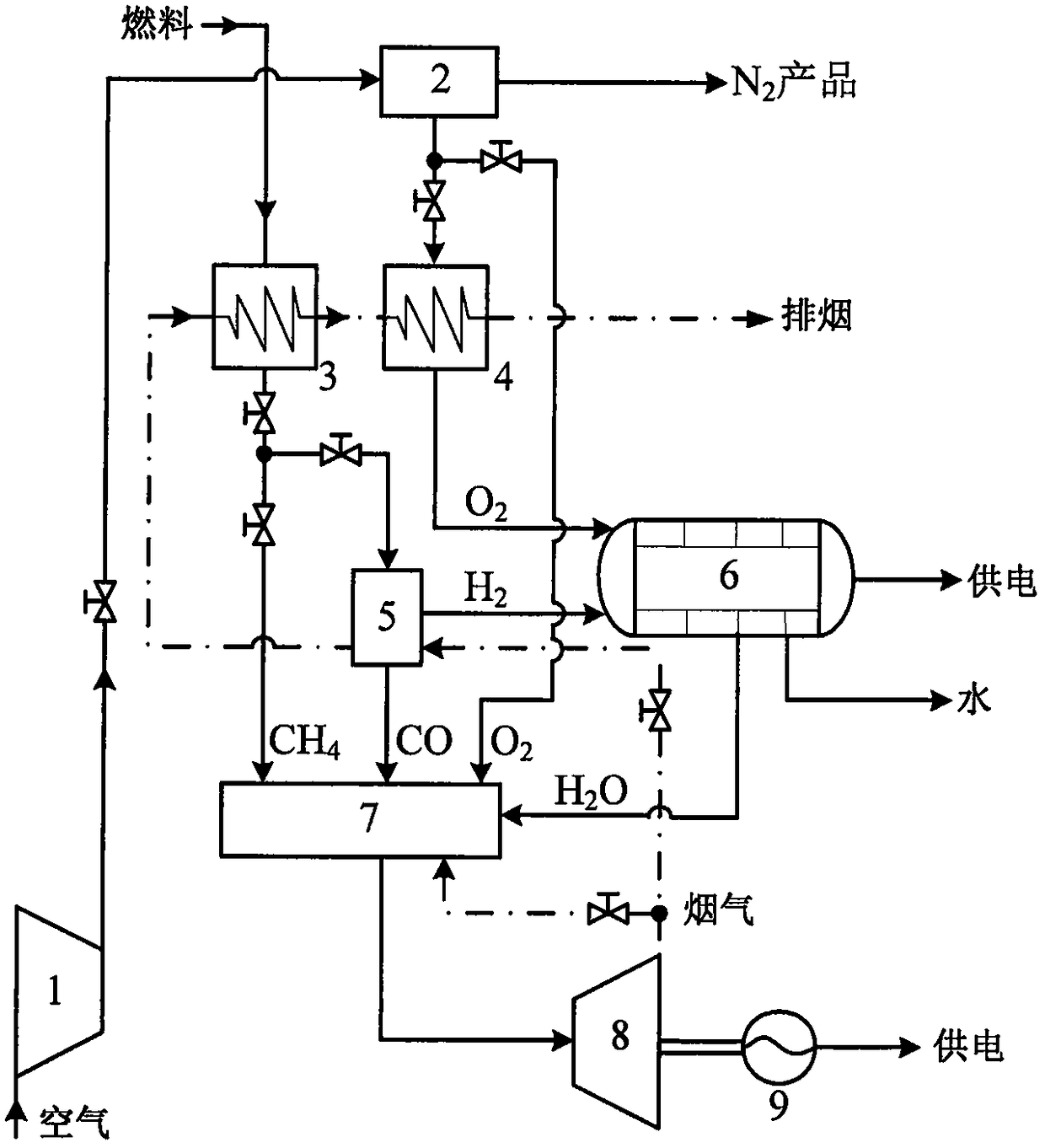

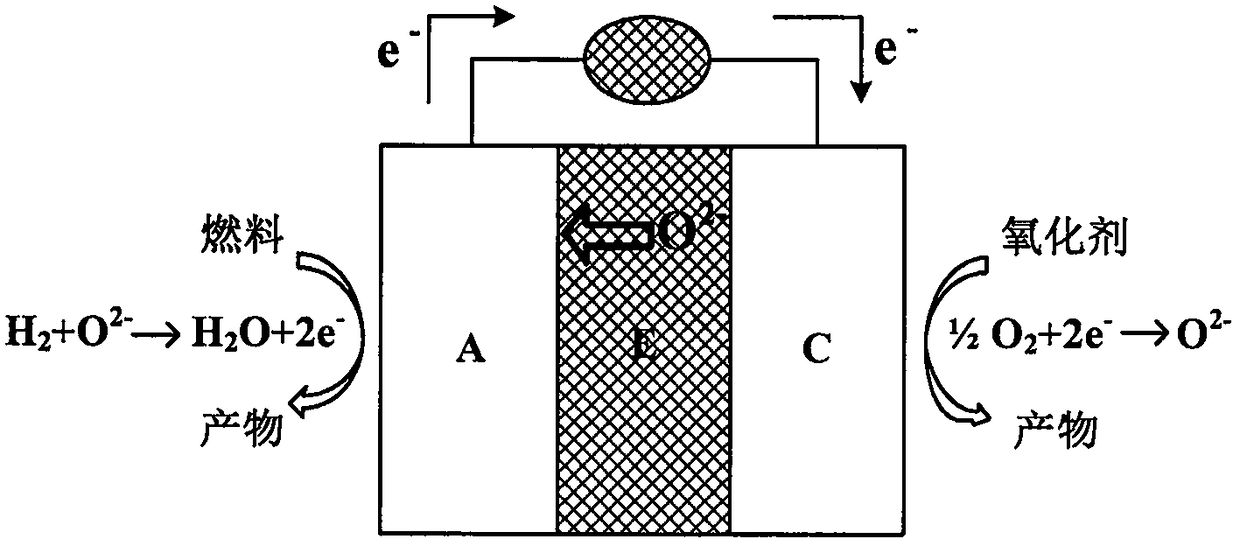

[0032] Such as figure 1 As shown, the system includes: compressor 1, air separator 2, fuel preheater 3, gas preheater 4, reformer 5, solid oxide fuel cell 6, combustor 7, turbine 8, generator 9 . The air enters the air separator 2 after being compressed by the compressor 1 to obtain O 2 and N 2 product, part O 2 After being heated by the gas preheater 4, it enters the solid oxide fuel cell 6, and the other part O 2 into the combustion chamber 7; with CH 4 After the main gaseous fuel is heated by the fuel preheater 3, part of it passes through the reformer 5 to obtain H 2 into the solid oxide fuel cell 6, with O 2 An electrochemical reaction occurs to form a solid oxide fuel cell power generation system; another part of the fuel, CO, O 2 , flue gas and some H in the product of solid oxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com