Renewable energy synthesis ammonia device and method

A renewable energy and ammonia synthesis technology, which is applied in the field of ammonia synthesis, can solve the problems of increased ammonia content, decreased adsorption performance, and the rate of ammonia synthesis that affect the nitrogen-hydrogen conversion rate, so as to increase the adsorption time, reduce the scale of the device, and improve the nitrogen-hydrogen conversion. rate as well as the effect of the rate of ammonia synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

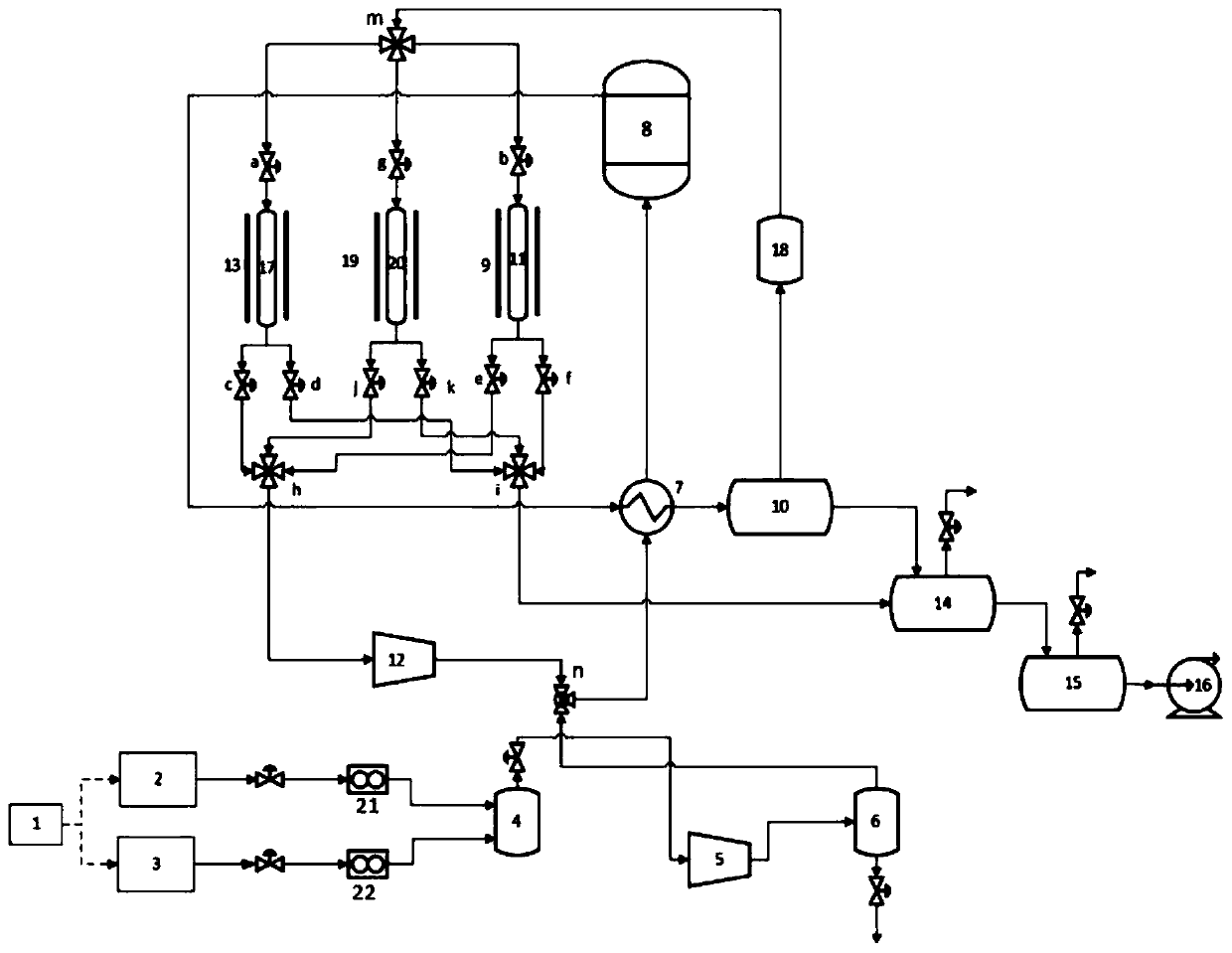

[0110] like figure 1 The shown renewable energy ammonia synthesis device includes an energy microgrid 1, an electrolyzed water hydrogen production device 2, an air separation unit 3, a first buffer tank 4, a first compressor 5, a second buffer tank 6, and a third buffer tank 18 , heat exchanger 7, reaction tower 8, first electric heating jacket 13, second electric heating jacket 9, third electric heating jacket 19, first adsorption column 17, second adsorption column 11, third adsorption column 20, the first A flash tower 10, a second flash tower 14, a third flash tower 15, a liquid ammonia pump 16, a second compressor 12, a first flow meter 21, a second flow meter 22 and valves;

[0111] The electrolytic water hydrogen production device 2 and the air separation device 3 are connected to the renewable power source energy microgrid 1 to produce hydrogen and nitrogen. The purity of hydrogen produced by the electrolytic water hydrogen production device is greater than 99.7%, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com