Odorless PE foam material and preparation method thereof

A foaming material and foaming agent technology, applied in the field of odorless PE foaming material and its manufacturing, can solve the problem of excessive decomposition of ammonia gas content, etc., and achieve the effect of uniform material, convenient processing, and increased fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

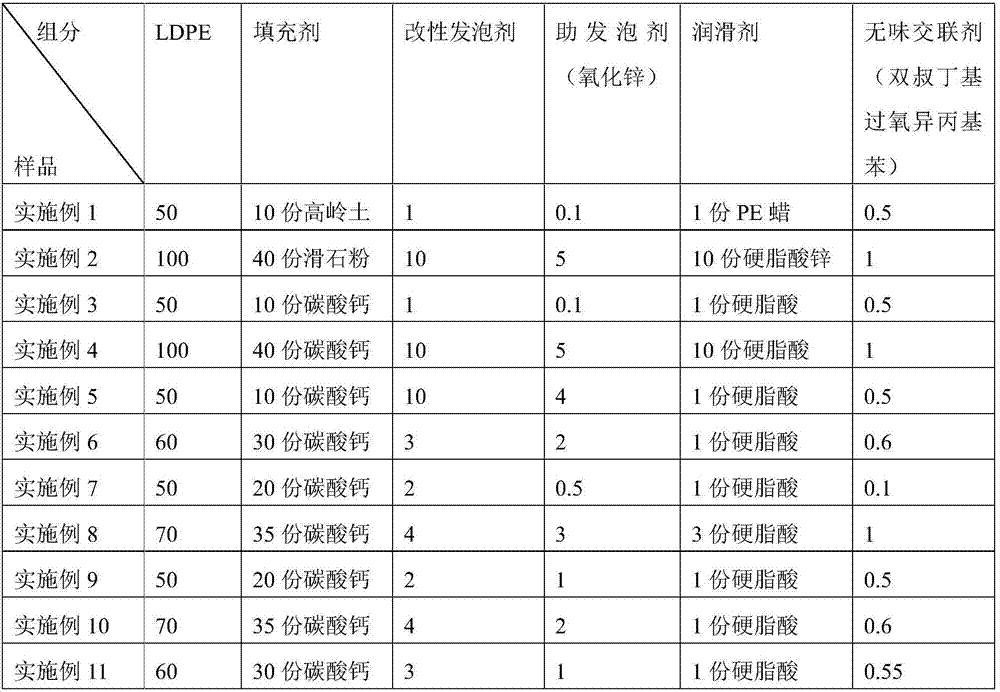

Examples

preparation example Construction

[0031] 2. Preparation of modified foaming agent

[0032] 2.1 Modified foaming agent: 85 parts by weight of azodicarbonamide, 7 parts of urea and 8 parts of cyanuric cyanurate are uniformly mixed to obtain a modified foaming agent.

[0033] 3. Sample manufacturing method

[0034] 3.1 Mixing: Add LDPE, filler, foaming aid and lubricant to the internal mixer and mix once under the condition of lower than 110°C. After mixing evenly, add the modified foaming agent prepared in 2.1 above, odorless Combined agent, mixing, the cooling water temperature in the internal mixer is 80±5°C, the compressed air pressure is 0.8±0.1MPa, and the material is discharged when the material temperature is 110±5°C;

[0035] Start practice: send the material discharged from the internal mixer into the open mixer to start the refinement, the temperature of the front roll is 90±5°C, the temperature of the rear roll is 75±5°C, the distance between the rolls is 0.5±0.2mm, and the retraining is performed 3 ...

Embodiment 1

[0042] Example 1: According to the components specified in Table 1, a PE foam material was manufactured by the manufacturing method in 3.1.

Embodiment 2

[0043] Example 2: According to the components specified in Table 1, a PE foam material was manufactured by the manufacturing method in 3.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com