Recovery method of catalyst triethylamine in acesulfame potassium production

A technology of acesulfame potassium and recovery method, which is applied in the field of recovery of catalyst triethylamine in the production of acesulfame potassium, which can solve the problems of environmental pollution and low recovery rate, and achieve the effects of reducing ammonia content and reducing the difficulty of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

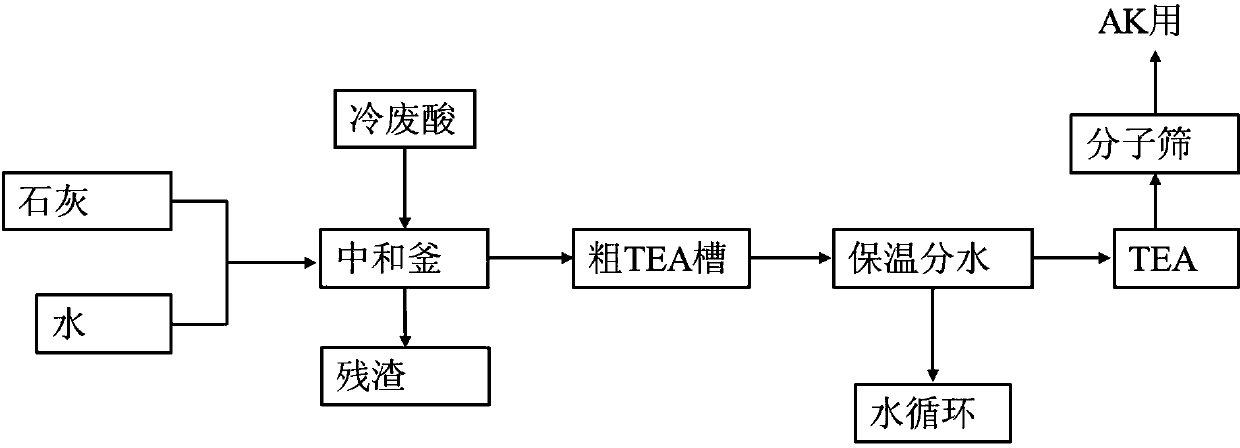

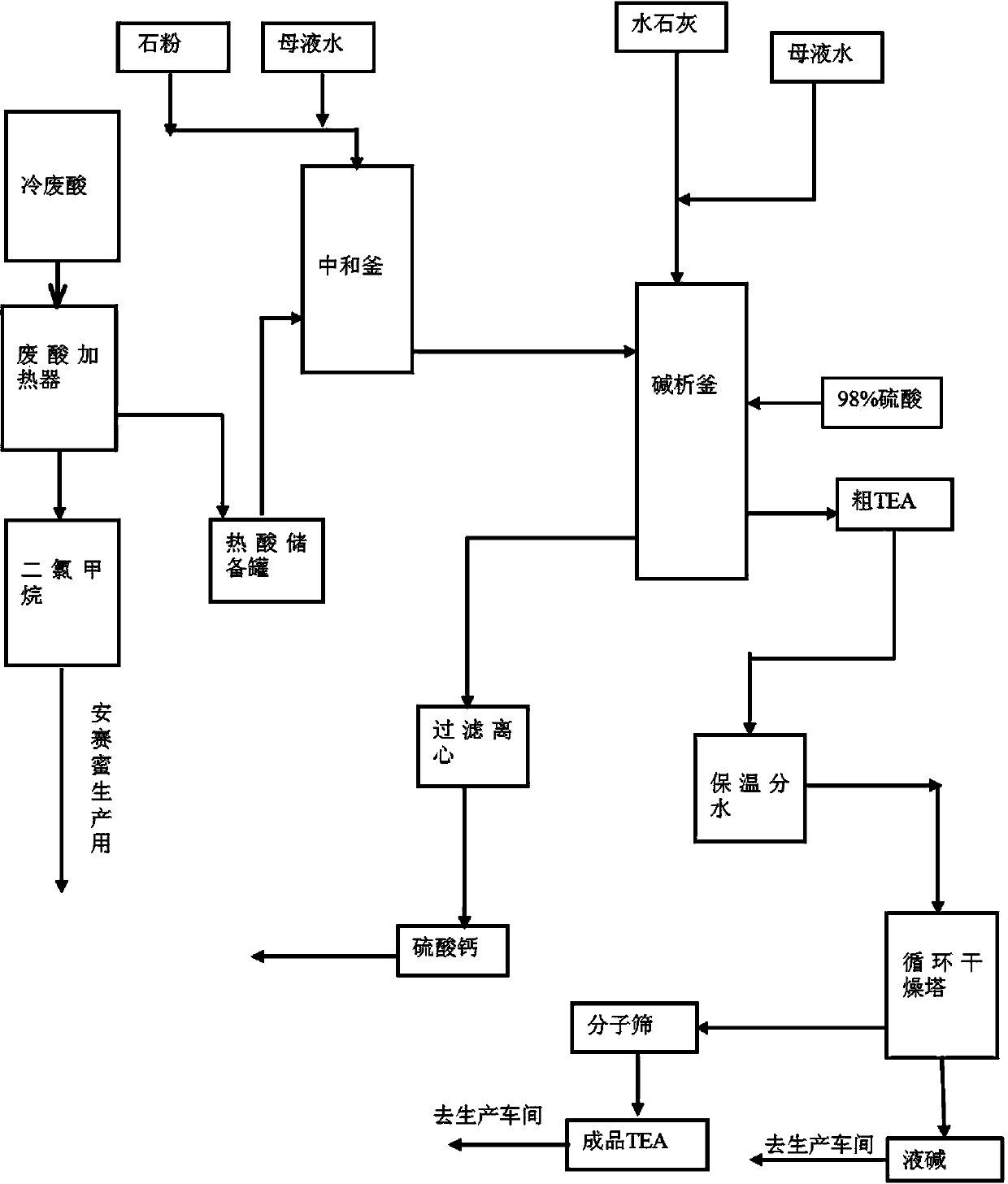

[0015] A method for recovering catalyst triethylamine in the production of acesulfame potassium, which is mainly characterized in that it comprises the following steps :

[0016] a. Preheat the waste acid (65-75°C) by passing the cold waste acid generated in the production through the pump, flow meter, and waste acid heater (65-75°C) for gas-liquid separation. The steam is dichloromethane and cooled by brine Recycling, as raw material for the production of acesulfame potassium; while the hot acid liquid is sent to the hot acid storage tank for use;

[0017] b. Mix the mother liquid water and stone powder (calcium carbonate) according to the ratio of 3:2.6 into the batching machine for stirring, mix evenly and then pump into the neutralization tank; then put about 6800 liters of hot acid in the hot acid storage tank at a speed of 20m3 / t Pumped into the neutralization tank, the mixture of hot acid, mother liquor, water and stone powder is neutralized at a ratio of 5.6:6.8, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com