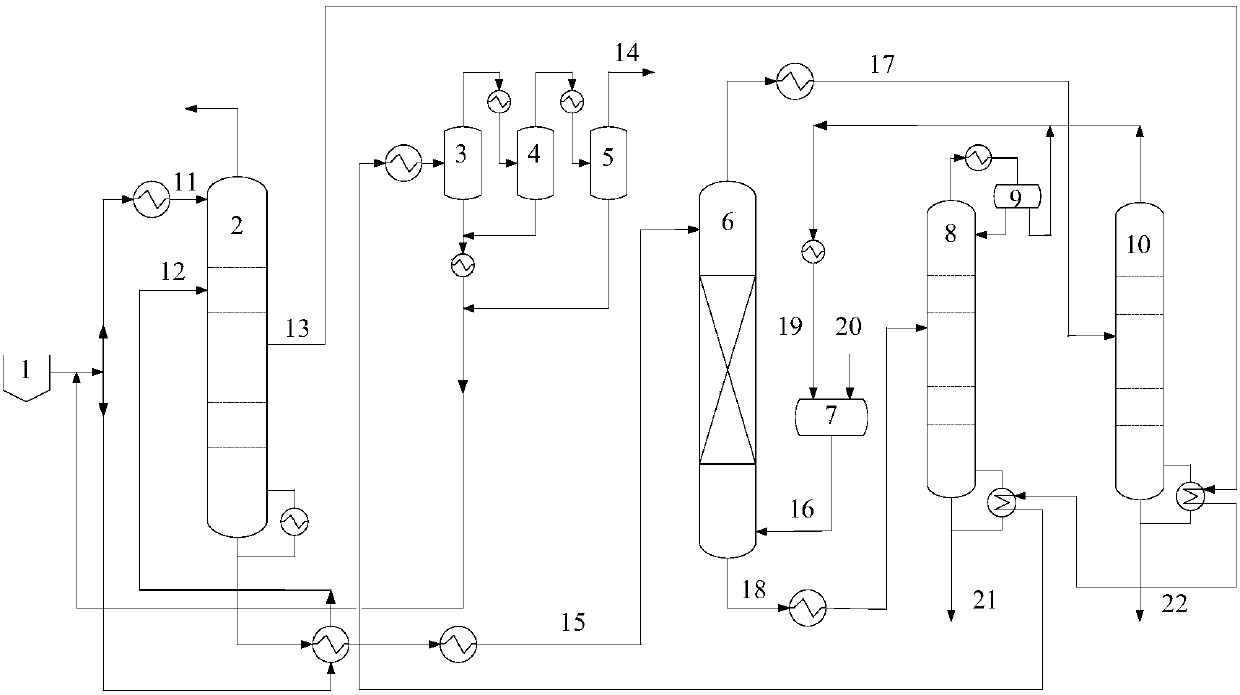

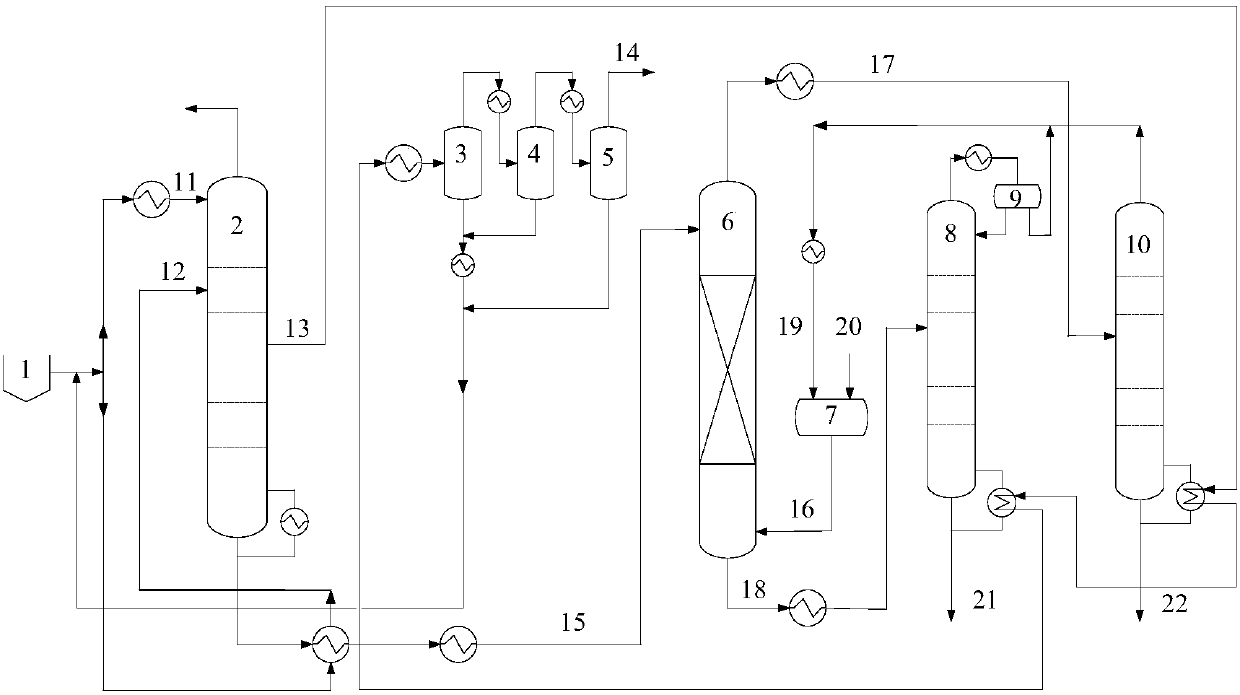

Coal gasification wastewater phenol and ammonia recovery process

A technology for the recovery of coal gasification wastewater and phenolic ammonia, which is applied in the fields of water pollutants, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve problems such as large steam consumption, save steam, reduce cost investment, steam Effect of dosage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] A company uses the Lurgi gasification process to produce coal-to-natural gas. The wastewater discharged during production has a flow rate of 100 tons / hour, containing 9000mg / L of ammonia, 4500mg / L of carbon dioxide, 600mg / L of hydrogen sulfide, and 6800mg / L of total phenols. According to the inventive method, take the following steps to process:

[0025] The coal gasification waste water discharged in the production is put into the settling tank first, and the solid particles are settled, and the upper layer waste water is pumped into the acid water stripping tower with side line extraction to carry out deacidification and deamination at the same time. The stripper tray number is 68. The waste water is divided into cold and hot streams, which enter the acid water stripping tower respectively. The volume ratio of cold and hot feeds is 1:4. The temperature of the cold feed at the top of the tower is 40°C, and the temperature of the hot feed is 163°C after heat exchange. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com