Muddy water separator used for town and country construction and technology thereof

A mud-water separation and separator technology, which is applied in water/sludge/sewage treatment, sludge treatment, multi-stage water treatment, etc., can solve the problems of space occupation, secondary pollution, and inconvenient operation, so as to reduce the treatment cost, Use flexible, practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

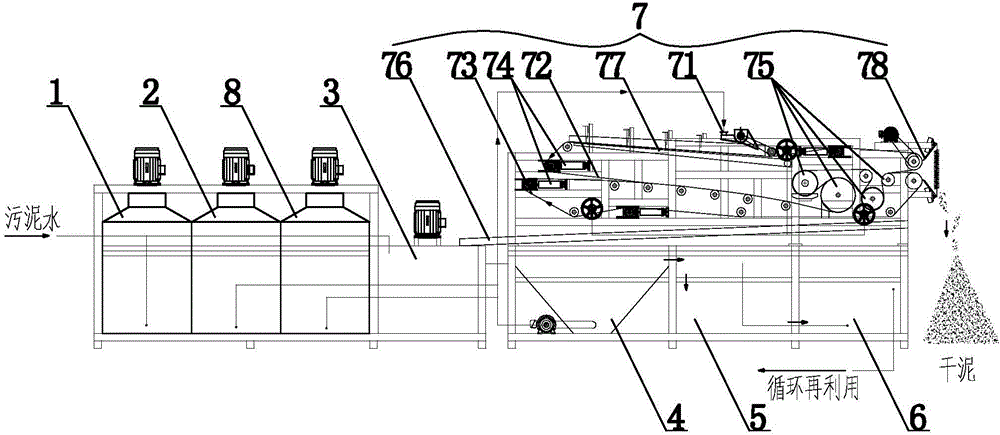

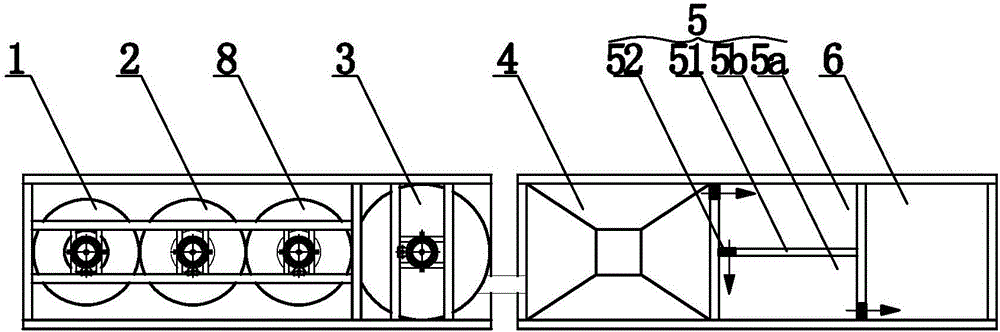

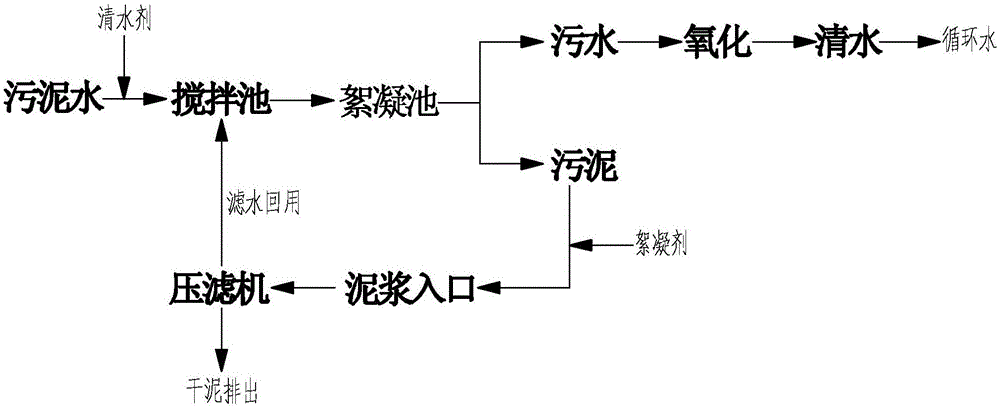

[0032] This embodiment is used for the mud-water separator in urban and rural construction, combined with figure 1 and figure 2, including water clearing agent tank 1, flocculant tank 2, stirring tank 3, flocculation tank 4, oxidation tank 5, clear water tank 6 and squeezing mechanism 7, water clearing agent tank 1 communicates with stirring tank 3, and provides water clearing agent for stirring tank 3 , the sludge water to be treated is pumped into the mixing tank 3, after adding water clearing agent and stirring treatment, it is sent to the flocculation tank 4 for standing treatment, and the upper sewage is sent to the oxidation tank 5 to form clear water after oxidation treatment, and then transferred to the clear water tank 6. Reuse as circulating water; the sludge in the lower layer is sent to the squeezing mechanism 7 through the mud inlet 71, and flocculant is added during the process of being transported to the mud inlet 71; the squeezing mechanism 7 mainly includes t...

Embodiment 2

[0042] The setting and working principle of this embodiment are the same as those of Embodiment 1, the difference is that the agent tank includes a water clearing agent tank 1, a flocculant tank 2 and a supplementary agent tank 8 for supplementing the flocculant. Conventional medicament tanks usually have a limited volume, coupled with the limitation of the operating environment, usually carry limited medicaments, and the supplementary medicament tank 8 can satisfy the sufficient and continuous process of the treatment process. The supplementary agent tank 8 can be used simultaneously with the corresponding flocculant tank 2, so that the agent can be added step by step, and the supply is relatively stable; it can also be used alone. When the flocculant tank 2 is supplied, it can be directly switched to the supplementary agent tank. 8, continue to supply without interrupting the separation of mud and water.

Embodiment 3

[0044] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference lies in: combining figure 2 A partition 51 is set in the middle of the oxidation tank 5, and a through hole 52 is arranged on the partition 51, so that the oxidation tank 5 is divided into two interconnected areas, and the supernatant in the flocculation tank 4 enters the first zone 5a along the direction of the arrow, and passes through After the oxidation treatment in the first area, it enters the second area 5b along the direction of the arrow to complete the secondary oxidation, the supernatant is converted into clean water, and the clean water enters the clear water pool 6 along the direction of the arrow. Wherein, the flocculation tank 4 communicates with the first zone 5a of the oxidation tank 5, and the second zone 5b of the oxidation tank 5 communicates with the clear water tank 6, which can effectively extend the walking path of the sewage in the oxidation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com