Aluminum alloy nickel plating pretreatment method

An aluminum alloy and pretreatment technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of difficult chemical sedimentation of heavy metal zinc ions, and the difficulty of discharging wastewater to meet the standards, and achieve increased quality stability and efficiency. Cost-effective, easy chemical settling, improved adhesion and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

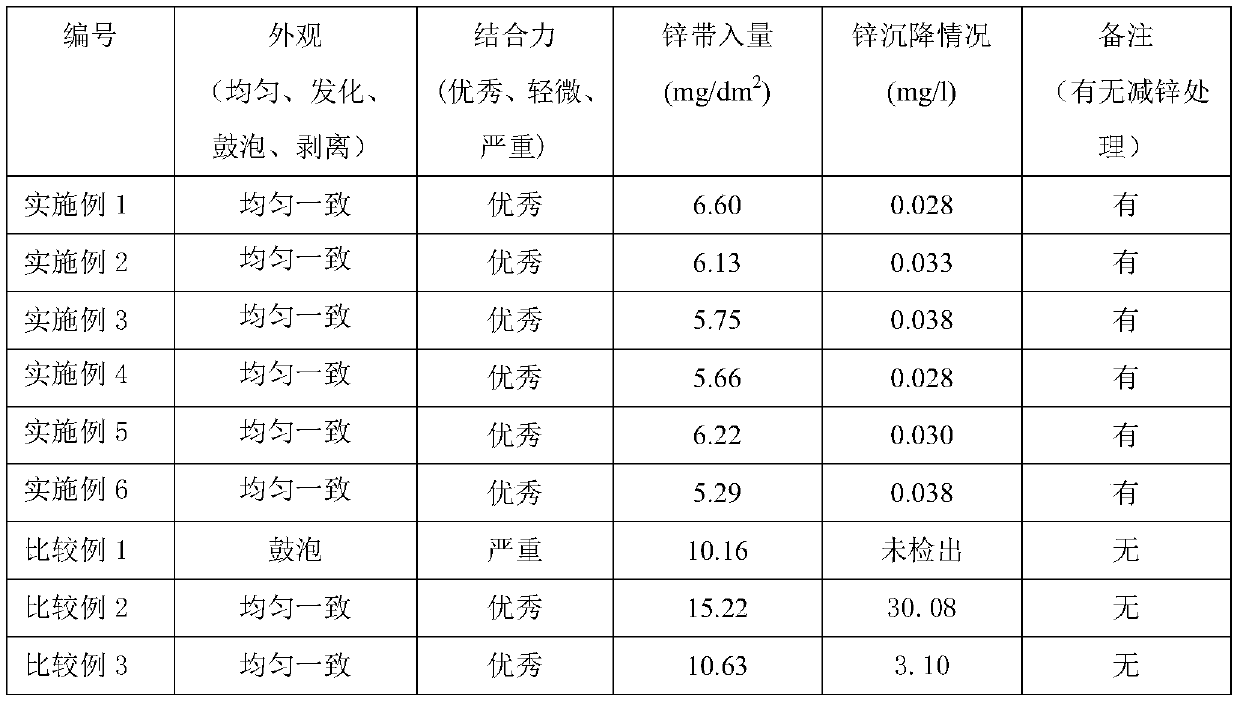

Examples

Embodiment Construction

[0034] Below in conjunction with embodiment the present invention is further explained. The following examples are only used to illustrate the present invention, but are not intended to limit the scope of the present invention.

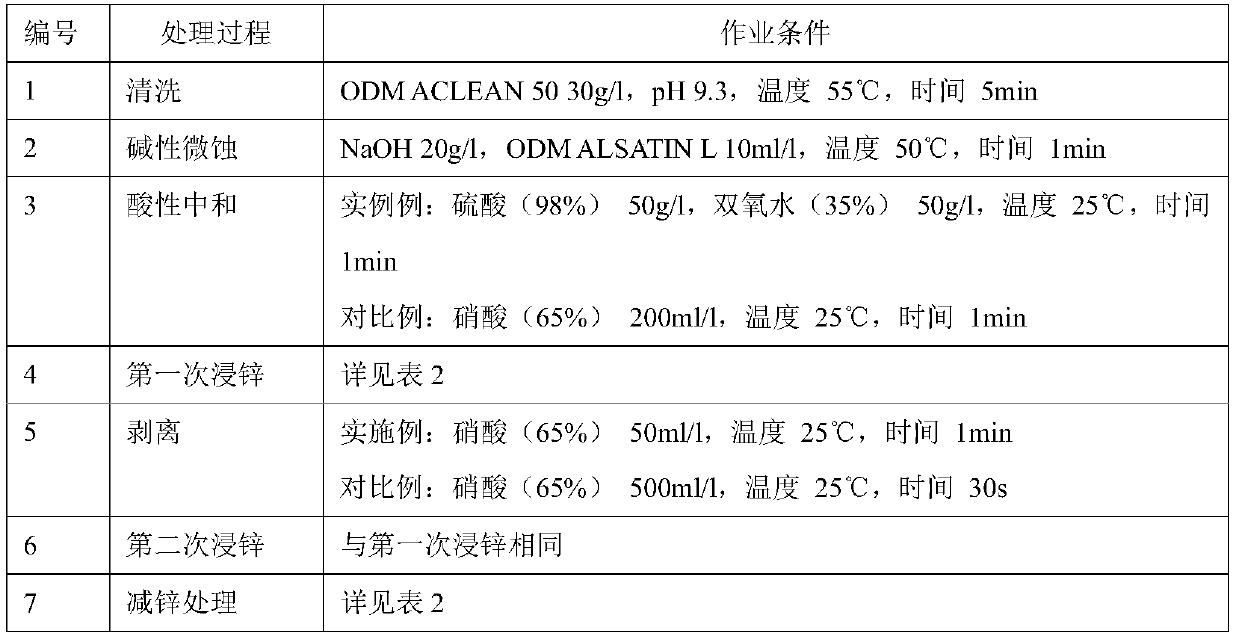

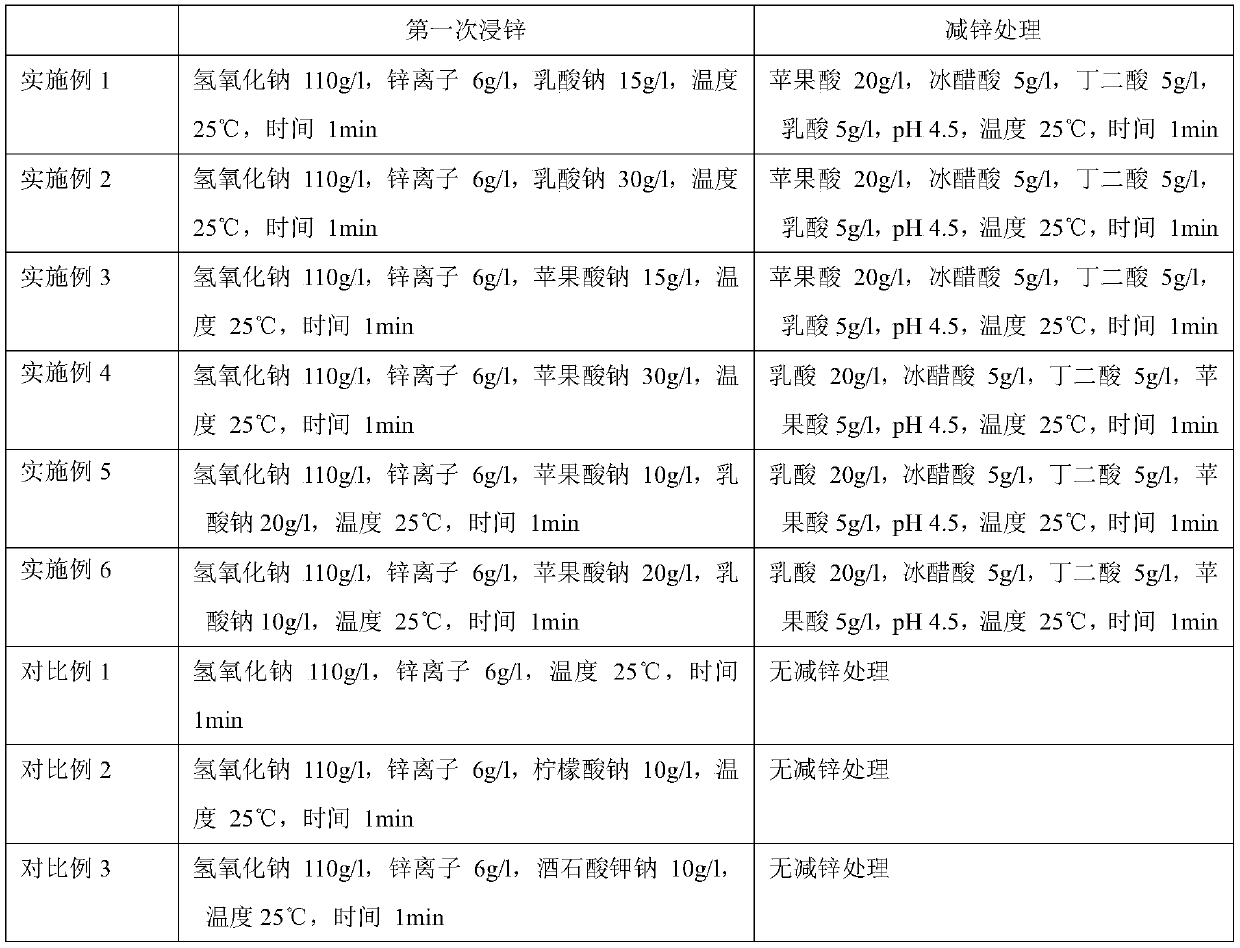

[0035] A kind of aluminum alloy nickel plating pretreatment method, comprises the steps:

[0036] 1) Cleaning: Put the aluminum alloy workpiece into the cleaning agent for cleaning. The cleaning agent is the phosphorus-free degreasing agent ODM ACLEAN 50 produced by Hangzhou Heyun Technology Co., Ltd., the concentration is 20-50g / l, and the operating temperature is 40-70°C , the soaking time is 2-10min; after that, wash it with water.

[0037] The invention uses a non-phosphorus degreasing agent for cleaning, reduces the use of phosphate, and is more environmentally friendly.

[0038] 2) Alkaline micro-etching: Put the cleaned and water-washed aluminum alloy workpiece into the alkaline etching solution for micro-etching. The alkaline etching solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com