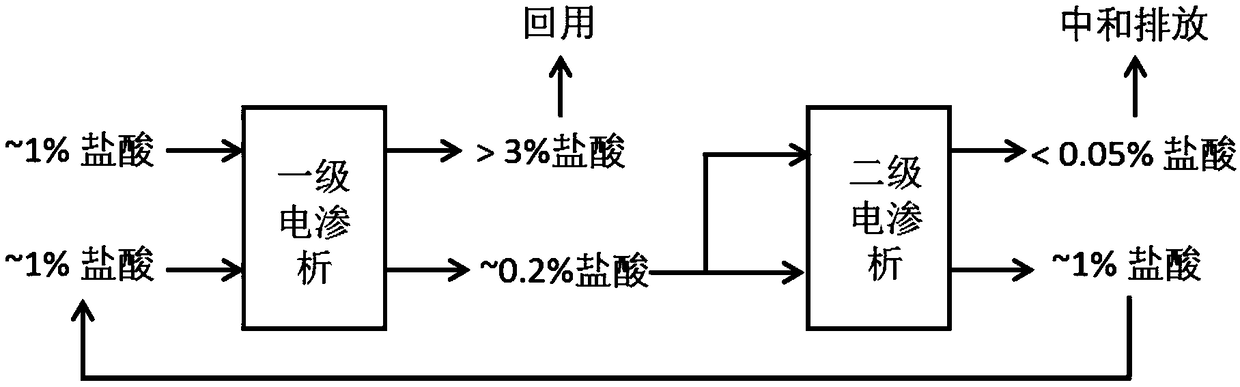

Method for concentrating wastewater containing hydrochloric acid by two-stage electrodialysis

A technology of one-stage electrodialysis and electrodialysis, which is applied in the field of two-stage electrodialysis to concentrate hydrochloric acid-containing wastewater, can solve the problems of no electrodialysis desalination solution treatment, etc., and achieve the effect of less alkali consumption and low salt concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

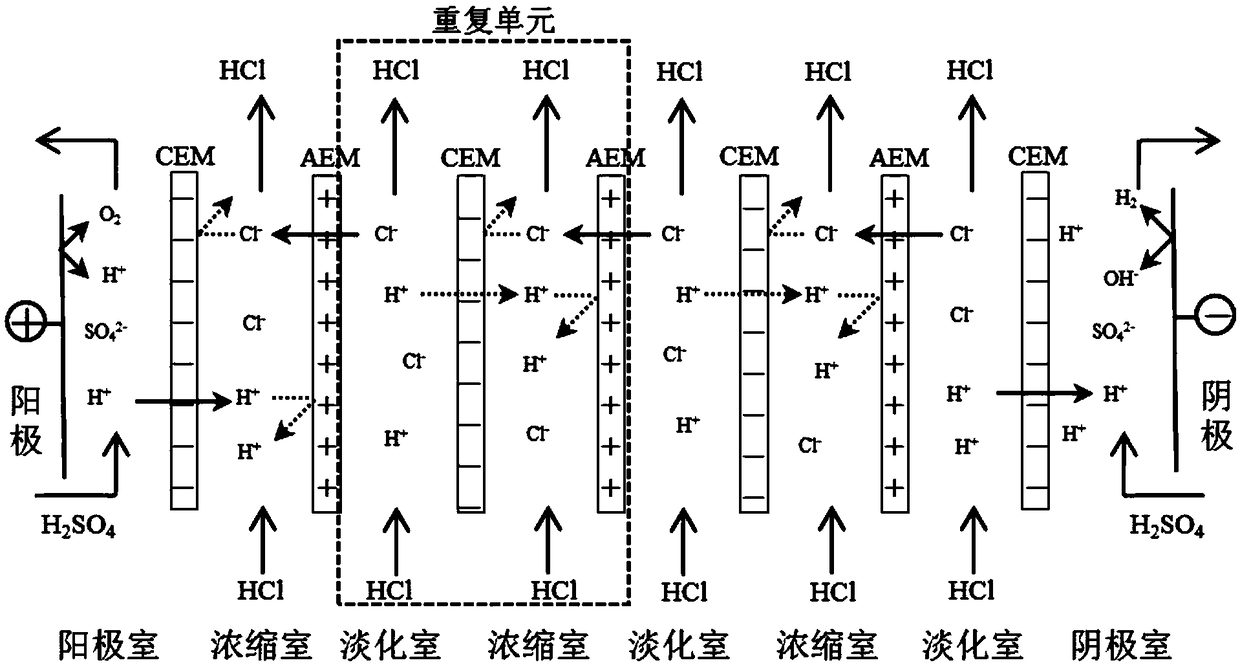

[0028] The hydrochloric acid-containing wastewater from a company in Shanghai was subjected to two-stage electrodialysis concentration, wherein the concentration of hydrochloric acid was 0.78%, and the content of impurity amino acids was 1%. The arrangement of the electrodialysis membrane stack used is: anode - anode chamber - [cation exchange membrane - concentration chamber - anion exchange membrane - desalination chamber] n - cation exchange membrane - cathode compartment - cathode, where n is 5. The cathode is connected to the negative pole of the power supply, and the anode is connected to the positive pole of the power supply. The cation exchange membrane in the membrane stack of the electrodialysis device used is CJMC-5 produced by Hefei Kejia Polymer Material Technology Co., Ltd., and the anion exchange membrane is the acid-blocking anion exchange membrane CJMA- produced by Hefei Kejia Polymer Material Technology Co., Ltd. 6. The limited area of single sheet film is...

Embodiment 2

[0032] The hydrochloric acid-containing wastewater from a company in Shanghai was subjected to two-stage electrodialysis concentration, wherein the concentration of hydrochloric acid was 0.78%, and the content of impurity amino acids was about 1%. The arrangement of the electrodialysis membrane stack used is: anode - anode chamber - [cation exchange membrane - concentration chamber - anion exchange membrane - desalination chamber] n - cation exchange membrane - cathode compartment - cathode, where n is 5. The cation exchange membrane in the membrane stack of the electrodialysis device used is CJMC-5 produced by Hefei Kejia Polymer Material Technology Co., Ltd., and the anion membrane is the acid-blocking anion exchange membrane CJMA-6 produced by Hefei Kejia Polymer Material Technology Co., Ltd. , the finite area of the sheet film is 189cm 2 .

[0033] The electrolytic solution added in the anode chamber and the cathode chamber is 0.15mol / L sulfuric acid solution during th...

Embodiment 3

[0036] The hydrochloric acid-containing wastewater from a company in Shanghai was subjected to two-stage electrodialysis concentration, in which the concentration of hydrochloric acid was 1.14%, and the content of impurity amino acids was about 1%. The arrangement of the electrodialysis membrane stack used is: anode - anode chamber - [cation exchange membrane - concentration chamber - anion exchange membrane - desalination chamber] n - cation exchange membrane - cathode compartment - cathode, where n is 5. The cation exchange membrane in the membrane stack of the electrodialysis device used is CJMC-5 produced by Hefei Kejia Polymer Material Technology Co., Ltd., and the anion membrane is the acid-blocking anion exchange membrane CJMA-6 produced by Hefei Kejia Polymer Material Technology Co., Ltd. , the finite area of the sheet film is 189cm 2 .

[0037]The electrolytic solution added in the anode chamber and the cathode chamber is 0.15mol / L sulfuric acid solution during th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com