Industrialized preparation method of 2-carboxyl-3-naphthalene formic acid

A naphthoic acid and industrial technology, applied in the field of industrial preparation of 2-carboxy-3-naphthoic acid, can solve problems affecting export competitiveness, unstable product quality, dark color, etc., and achieve high energy utilization rate and low production cost Low, the effect of production process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

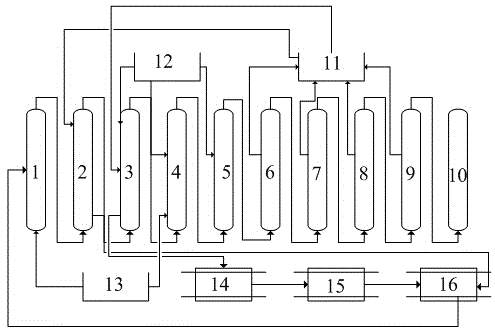

[0014] Such as figure 1 A kind of production technique of industrial preparation 2-carboxy-3 naphthoic acid shown is characterized in that the technique comprises first reaction tower 1, carboxylation reaction tower 2, second reaction tower 3, neutralization reaction tower 4, acid analysis Reaction tower 5, filter press reaction tower 6, fine filtration reaction tower 7, dehydration reaction tower 8, drying reaction tower 9, finished product storage tower 10, waste water treatment system 11, acid addition equipment 12, alkali addition equipment 13, resin filtration system 14 , naphthol recovery system 15, naphthol storage tank 16 etc.; Road connects the inlet of carboxylation reaction tower 2, by calculation, throws the 2-naphthol of corresponding amount to first reaction tower 1. Raise the temperature of the material, and when the temperature of the material in the tower rises to about 110°C, start stirring, rapidly raise the temperature to 125°C±5°C, and keep the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| stone rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com