Device and method for carrying out low-concentration SO2 flue gas desulfurization by utilizing fuzzy alkali-feeding method

A kind of SO2, low concentration technology, applied in the fields of environmental protection, chemical industry and smelting, to reduce labor intensity, eliminate untimely control, and facilitate control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

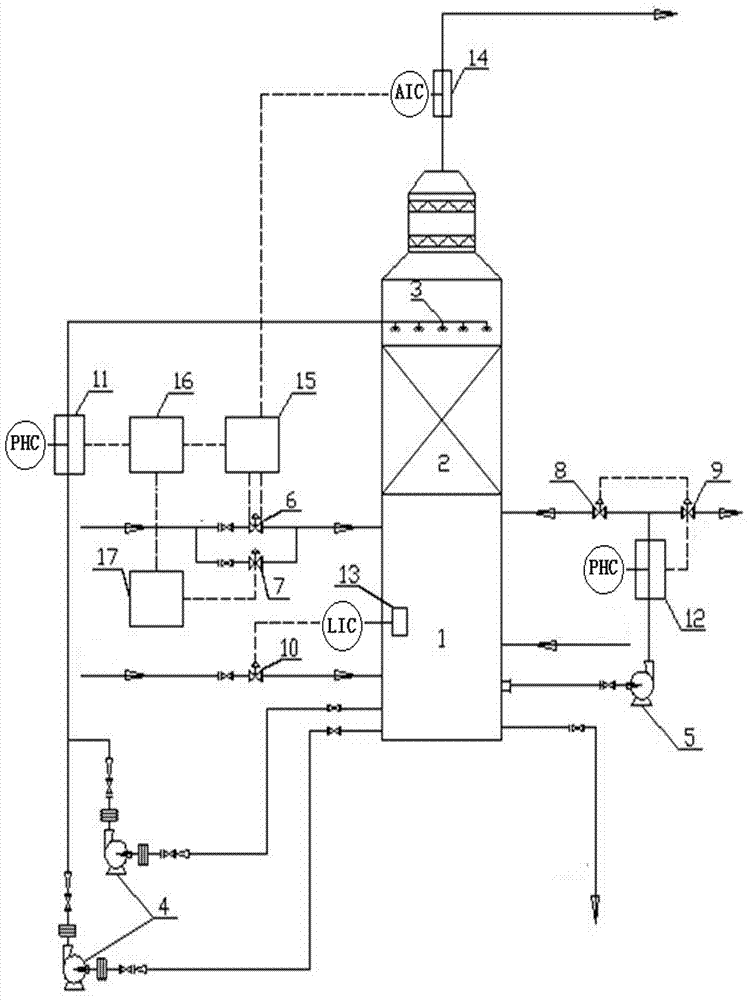

[0038] The above-mentioned low-concentration SO 2 The flue gas desulfurization device is applied to a certain low concentration of SO in normal production 2 flue gas (SO 2 Concentration: 190mg / Nm 3 -1882mg / Nm 3 , with an average concentration of 890mg / Nm 3 , Flue gas volume: 163310Nm 3 / h-200206Nm 3 / h, the average gas volume is 180425Nm 3 / h) in desulfurization, due to SO 2 The concentration is low, and only fuzzy alkali addition can make the flue gas discharge up to the standard. The specific steps include the following steps: the operator switches the chain control on the DCS system of the central control room to the pH value of the main circulation system to control the alkali addition, and the alkali addition The pH value of the absorption liquid in the interlocking main circulation system is usually set at 4.8. When the pH value of the absorption liquid in the main circulation pipeline is less than 4.8, the pH signal is output through the signal isolator, and the ...

Embodiment 2

[0040] In this embodiment, the fuzzy alkali addition method is used to carry out low-concentration SO 2 The device of flue gas desulfurization is the same as embodiment 1, when it is applied to abnormal production, SO 2 A certain SO under the condition of unstable concentration 2 flue gas (SO 2 Concentration: 22mg / Nm 3 -14040mg / Nm 3 , average concentration: 5250mg / Nm 3 ;Smoke volume: 88298Nm 3 / h-190250Nm 3 / h, average gas volume: 129927Nm 3 In the desulfurization of / h), the following steps are specifically included: the operator switches the chain control to adopt the flue gas outlet SO on the DCS system of the central control room 2 Concentration control and alkali addition, alkali addition chain flue gas outlet SO 2 The concentration is usually set at 250mg / Nm 3 , when the desulfurization tower flue gas outlet SO 2 Concentration higher than 250mg / Nm 3 When the main soda adding valve is opened, the lye in the high tank will be added to the desulfurization tower t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com