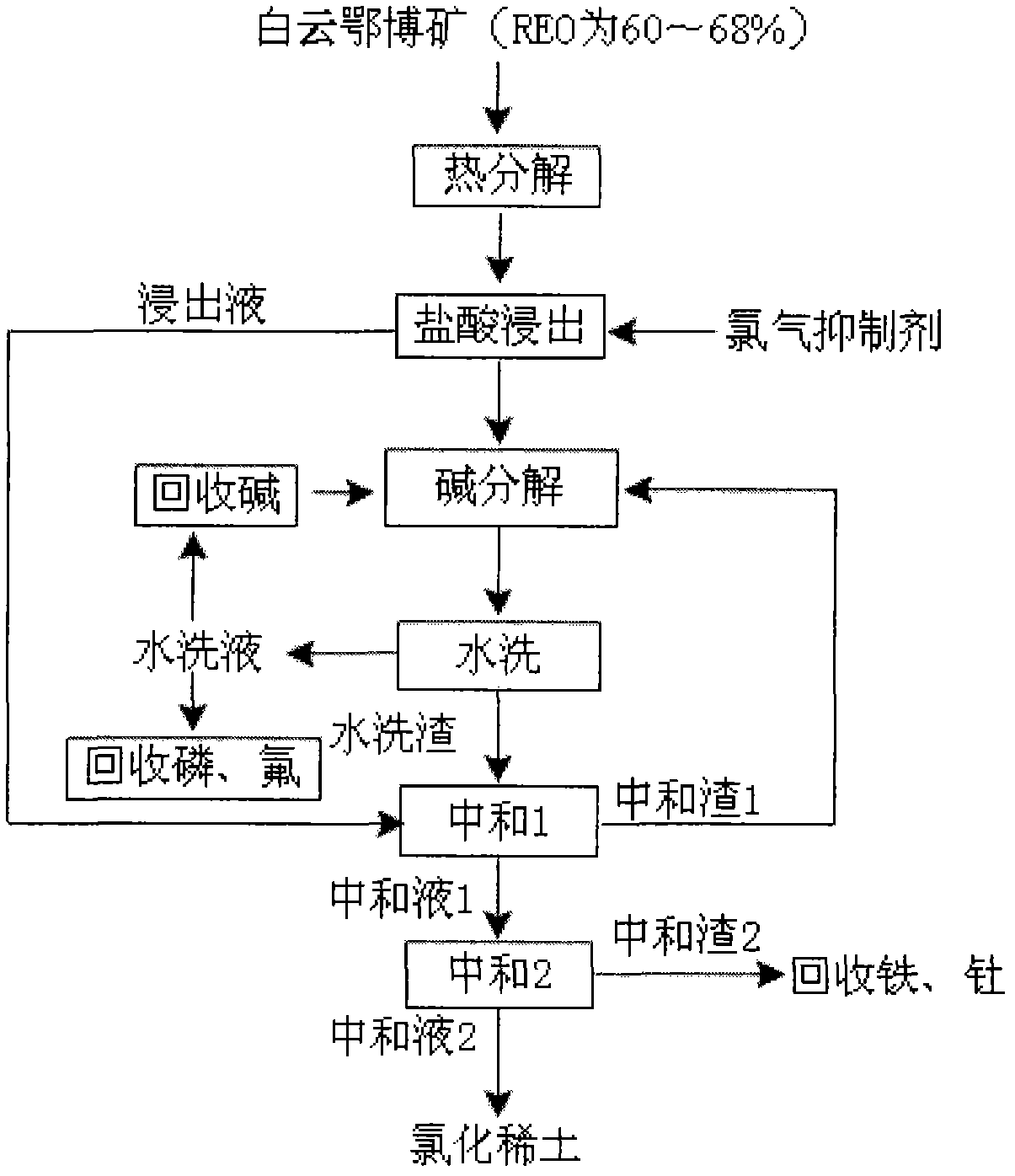

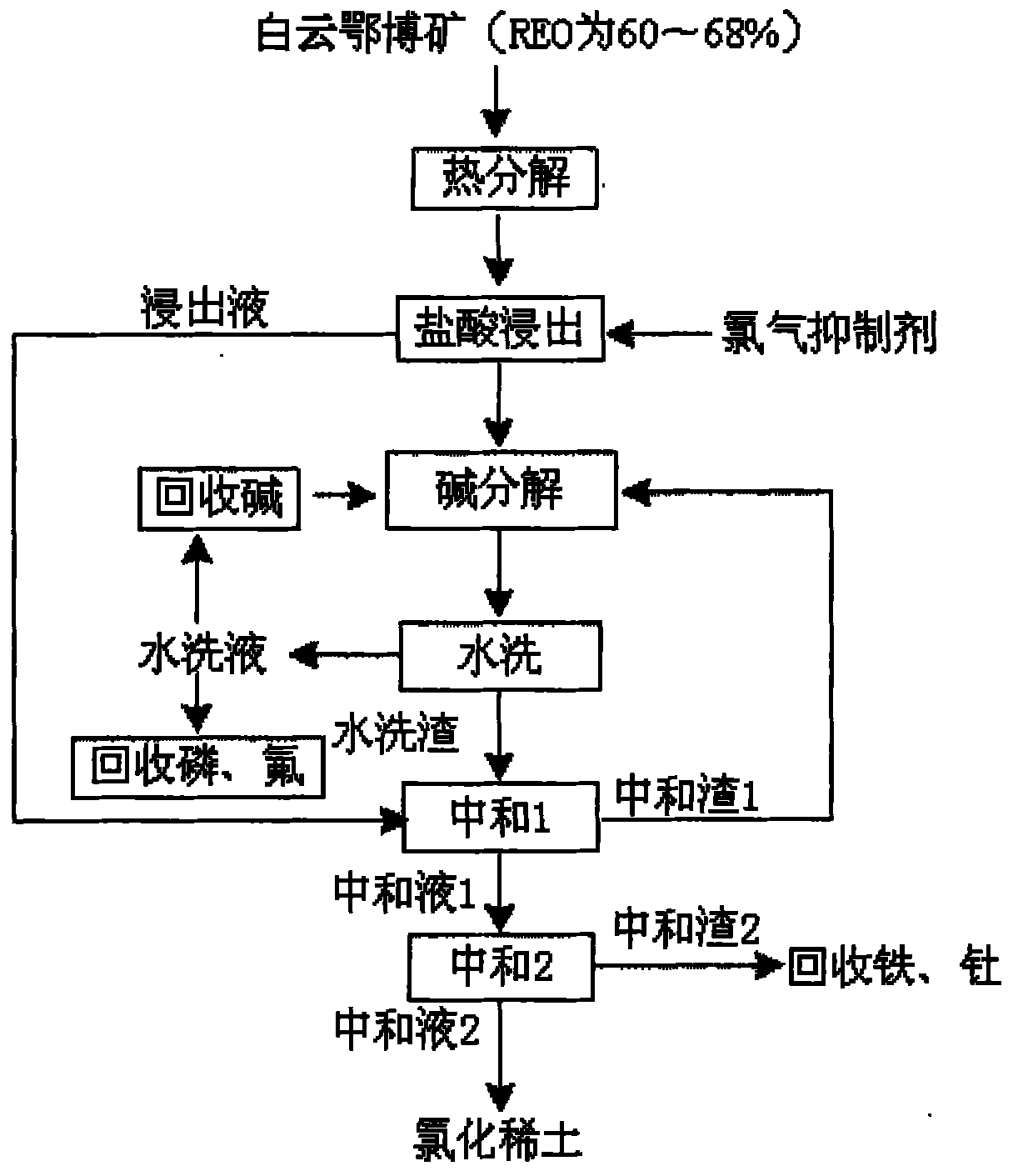

A New Method for Preparing Rare Earth Chloride from Baiyun Obo Rare Earth Concentrate

A rare earth concentrate and rare earth chloride technology, applied in the field of hydrometallurgy, can solve the problems of high rare earth recovery rate and three waste pollution, etc., and achieve the effects of high rare earth recovery rate, low alkali consumption, easy preservation and recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) thermal decomposition: get 1.5kg grade and be 60.2% Baiyun Obo ore and carry out thermal decomposition, the temperature of thermal decomposition is 420 ℃, and the time is 1.5 hours;

[0026] (2) Hydrochloric acid leaching: the thermally decomposed Baiyun Obo ore is leached with hydrochloric acid, the concentration of hydrochloric acid is 7mol / L, the amount of hydrochloric acid: the quality of REO in the Baiyun Obo mine: the quality of concentrated hydrochloric acid=1:2.2, the leaching temperature is 75 ° C, the time For 1.5 hours, add thiourea as a chlorine gas inhibitor during the leaching process. Addition amount: REO quality in Baiyun Obo rare earth concentrate: chlorine gas inhibitor = 1:0.06. Filter the thermally decomposed minerals after hydrochloric acid leaching to obtain hydrochloric acid leachate and hydrochloric acid leach residue;

[0027] (3) Alkali decomposition: adopt sodium hydroxide to carry out alkali decomposition to hydrochloric acid leaching sla...

Embodiment 2

[0032] (1) thermal decomposition: take 1.5kg of Baiyun Obo ore with a grade of 65.36% for thermal decomposition, the temperature of thermal decomposition is 490°C, and the time is 1.0 hour;

[0033] (2) Hydrochloric acid leaching: the thermally decomposed Baiyun Obo mine is leached with hydrochloric acid, the concentration of hydrochloric acid is 10mol / L, the amount of hydrochloric acid: the quality of REO in the Baiyun Obo mine: the quality of concentrated hydrochloric acid=1:1.7, the leaching temperature is 75°C, the time 1.5 hours, adding H during leaching 2 o 2 As a chlorine gas inhibitor, the addition amount: REO quality in Baiyun Obo rare earth concentrate: chlorine gas inhibitor = 1:0.3, filter the thermally decomposed minerals after hydrochloric acid leaching, and obtain hydrochloric acid leaching solution and hydrochloric acid leaching residue;

[0034] (3) Alkali decomposition: adopt sodium hydroxide to carry out alkali decomposition to hydrochloric acid leaching sl...

Embodiment 3

[0039] (1) thermal decomposition: get 1.5kg grade and be 67.65% Baiyun Obo ore and carry out thermal decomposition, the temperature of thermal decomposition is 5500, and the time is 0.5 hour;

[0040] (2) Hydrochloric acid leaching: the thermally decomposed Baiyun Obo mine is leached with hydrochloric acid, the concentration of hydrochloric acid is 6mol / L, the amount of hydrochloric acid: REO quality in Baiyun Obo mine: the quality of concentrated hydrochloric acid=1:1.6, the leaching temperature is 95 ° C, the time For 1.0 hour, sodium sulfide was added as a chlorine gas inhibitor during the leaching process. Addition amount: REO quality in Baiyun Obo rare earth concentrate: chlorine gas inhibitor = 1:0.07. Filter the thermally decomposed minerals after hydrochloric acid leaching to obtain hydrochloric acid leachate and hydrochloric acid leach residue;

[0041](3) Alkali decomposition: adopt sodium hydroxide to carry out alkali decomposition to hydrochloric acid leaching slag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com