Efficient separating purifying technique for lignin, hemi-cellulose and cellulose

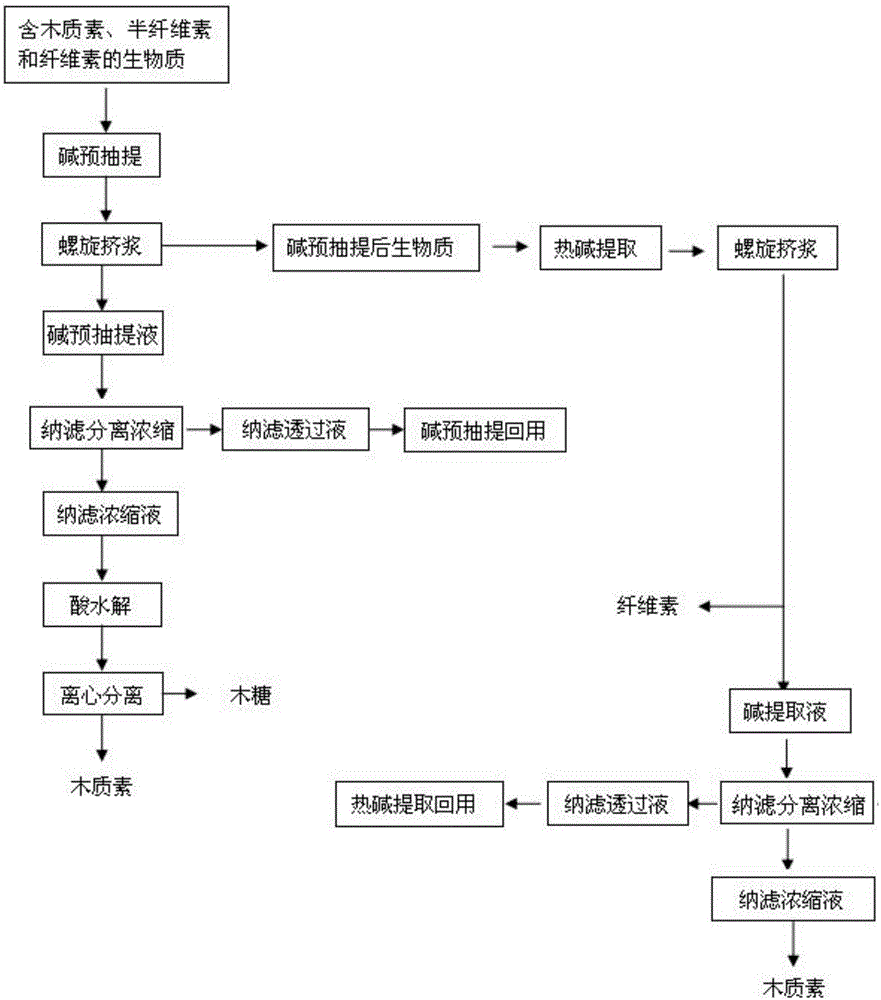

A technology of hemicellulose and lignin, which is applied in the field of high-efficiency separation and purification technology, can solve the problems of insufficient separation and extraction of lignin, hemicellulose and cellulose, the recovery rate of single components, and the inability to recycle, etc., to achieve economical improvement Benefits and social benefits, the effect of lowering temperature and reducing alkali consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Step 1, 10Kg of water content is that the bagasse (removing pith) of 50wt% is placed in the digester, according to the quality of the absolutely dry bagasse and the total liquid mass (the quality of the water in the bagasse and the quality of the NaOH solution added) The ratio of the sum) is 1:8, 35Kg of NaOH solution with a mass concentration of 11.43% is added, and the mass of NaOH is adjusted to 10% of the total liquid mass; The bagasse is subjected to alkali pre-extraction; then a screw press is used for solid-liquid separation to obtain 35.4Kg of alkali pre-extraction solution and 7.75Kg of bagasse after alkali extraction. The content of pentose in the alkali pre-extraction solution is 2.45wt %, the mass concentration of NaOH is 10.4%.

[0056] In step 2, the 35.4Kg alkali pre-extraction solution obtained in step 1 is subjected to nanofiltration separation and concentration, using a roll-type nanofiltration membrane module with a molecular weight cut-off of 600 Dal...

Embodiment 2

[0065] Step 1. Place 3Kg of corn stalks with a moisture content of 10wt% in the digester, and according to the quality of the absolutely dry corn stalks and the total liquid mass (the sum of the quality of the water content in the corn stalks and the mass of the added NaOH solution) The ratio is 1:8, 21.3Kg of NaOH solution with a mass concentration of 10.14% is added, and the mass of NaOH is adjusted to be 10% of the total liquid mass; Alkali pre-extraction is carried out; then a screw press is used for solid-liquid separation to obtain 18.6Kg of alkali pre-extraction solution and 4.72Kg of corn stover after alkali extraction. The content of pentose in the alkali pre-extraction solution is 3.25wt%, The mass concentration of NaOH was 9.92%.

[0066] Step 2: Perform nanofiltration separation and concentration on the 18.6Kg alkali pre-extraction solution obtained in Step 1, using a roll-type nanofiltration membrane module with a molecular weight cut-off of 800 Daltons, the membr...

Embodiment 3

[0075] Step 1, be that 55.47wt% bamboo chips (here chooses Cizhu) of 55.47wt% are placed in the digester, according to the quality of the absolutely dry bamboo chips (the quality of the moisture content in the bamboo chips and the quality of the NaOH solution that adds) The ratio of the sum) to the total liquid mass is 1:6, add 10.6Kg of NaOH solution with a mass concentration of 6.3%, and adjust the NaOH mass to 5% of the total liquid mass; the digester is heated with heat transfer oil, and when the temperature reaches 140 ℃ Incubate for 2h, and carry out alkali pre-extraction on the bamboo chips; then use a screw press for solid-liquid separation to obtain 12.24Kg of alkali pre-extraction solution and 2.72Kg of alkali-extracted bamboo chips. The pentose in the alkali pre-extraction solution is obtained. The content is 2.10wt%, and the mass concentration of NaOH in the alkali pre-extraction solution is 4.5%.

[0076] In step 2, the 12.24Kg alkali pre-extraction solution obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com