Sewage treatment process and sewage treatment system thereof

A sewage treatment system and sewage treatment technology, applied in biological water/sewage treatment, adsorbed water/sewage treatment, water/sewage multi-stage treatment, etc. Low problems, to achieve the effect of small residual sludge, easy cleaning and high oxygen utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

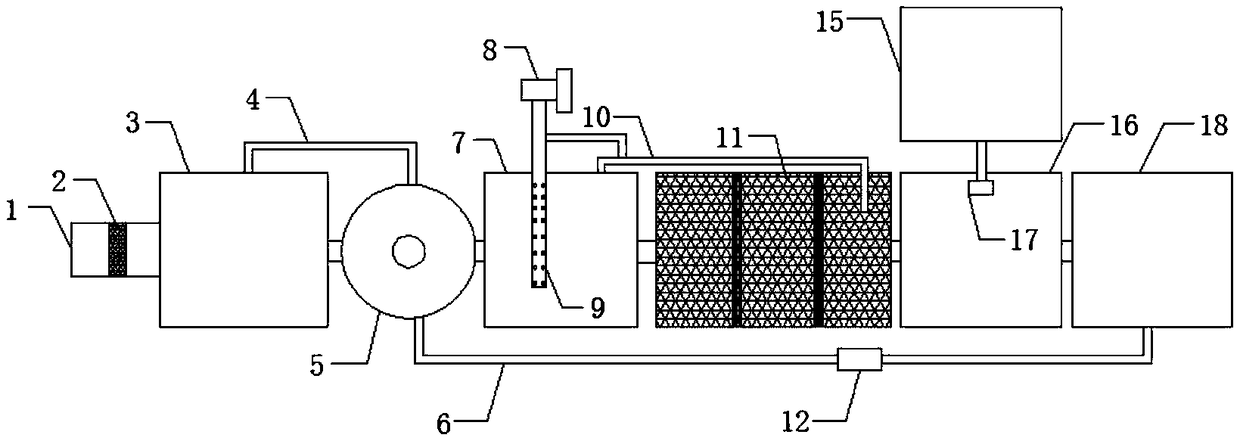

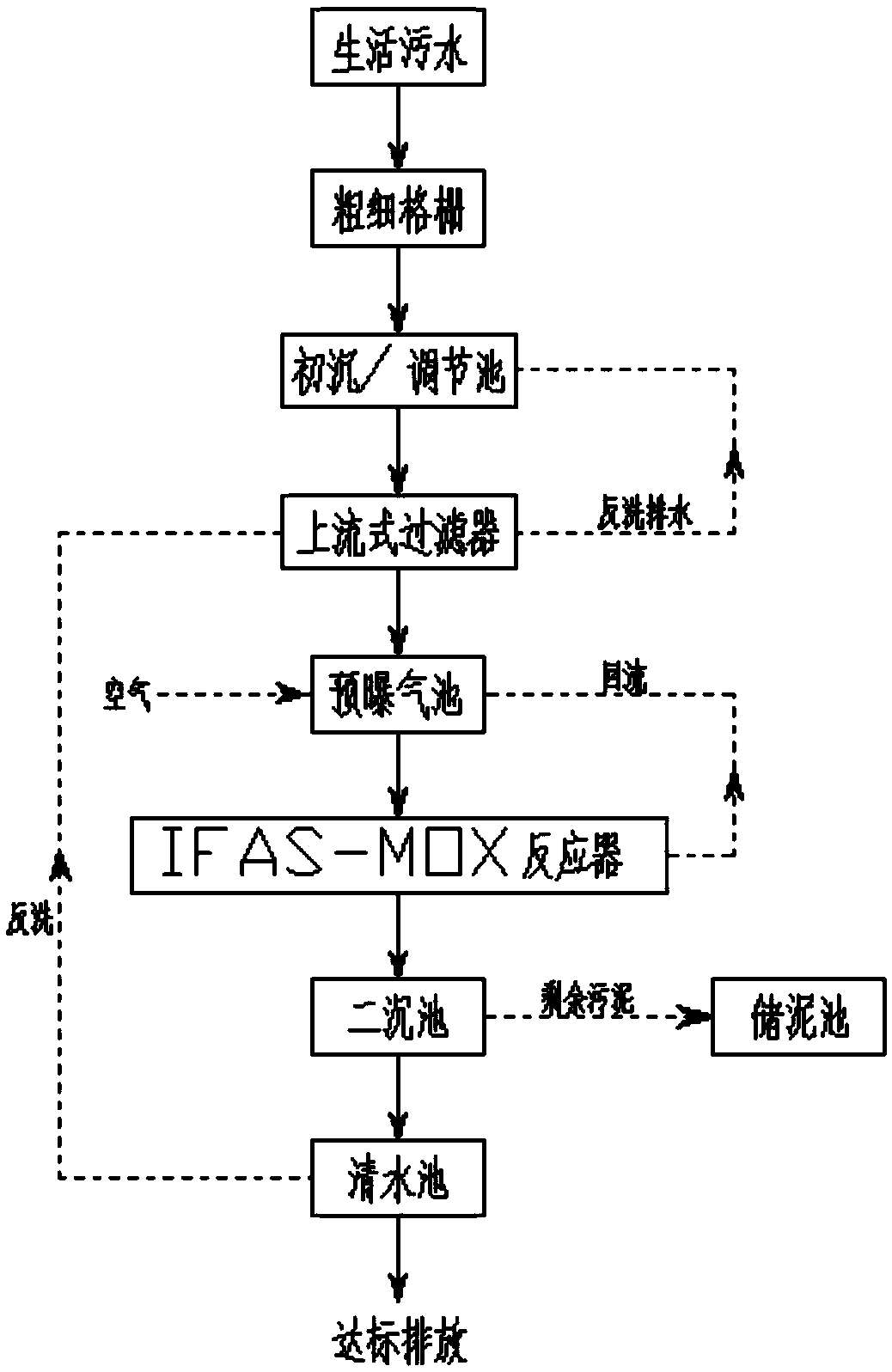

[0021] Please refer to Figure 1-6 As shown, a sewage treatment process and its sewage treatment system include a primary sedimentation / adjustment tank 3, an upflow filter 5, a pre-aeration tank 7, an IFAS-MOX reactor 11, a secondary sedimentation tank 16 and clear water connected in sequence Pool 18, one side of the primary sedimentation / adjustment pool 3 is provided with a sewage inlet tank 1, and a thick and thin grille 2 is installed in the sewage inlet tank 1, and a microporous aeration tube 9 is installed on the bottom of the pre-aeration tank 7, and the microporous One end of the aeration pipe 9 communicates with the blower fan 8 positioned outside the pre-aeration tank 7, and the IFAS-MOX reactor 11 is connected in series in multiple stages, and the water outlet of the IFAS-MOX reactor 11 is installed with a fan connected to the pre-aeration tank 7. The return pipe 10 and the clean water tank 18 are connected to the upflow filter 5 through the backwash water pipe 6, an...

Embodiment 2

[0025] This embodiment provides a sewage treatment process and a sewage treatment system thereof, which are roughly the same as the sewage treatment system and sewage treatment process in Example 1, except that multiple grid holes are installed in the sewage inlet tank 1 to gradually reduce Small thick and thin grids 2, so as to gradually remove large suspended solids and impurities of different volumes in the sewage to prevent the grid from clogging, and then pass through the primary sedimentation / adjustment tank 3, upflow filter 5, pre-aeration tank 7, IFAS -MOX reactor 11, secondary sedimentation tank 16 and clear water tank 18 are processed.

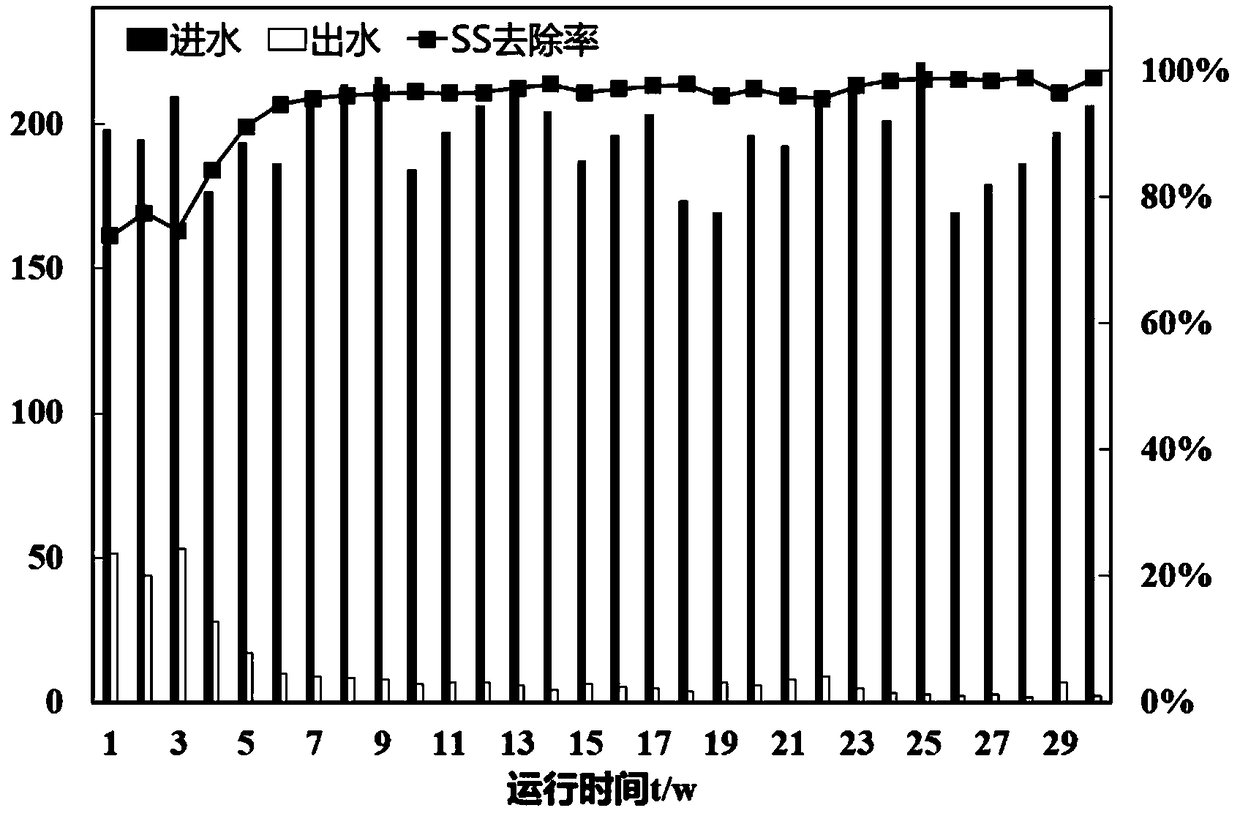

[0026] The present invention utilizes the advantages of the upflow filter, which is not easy to be blocked, has a fast filtering speed, and is easy to clean, to realize sewage pretreatment; utilizes the advantages of biofilm technology and activated sludge technology in the IFAS-MOX reactor, without increasing the sludge concentration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com