High-concentration N-phenylmaleimide reaction liquid post-treatment process

A maleimide and reaction liquid technology, applied in the field of fine chemicals, can solve the problems of unmentioned yield, long overall process, affecting yield, etc., achieve rapid layering, reduce alkali consumption, and avoid three wastes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

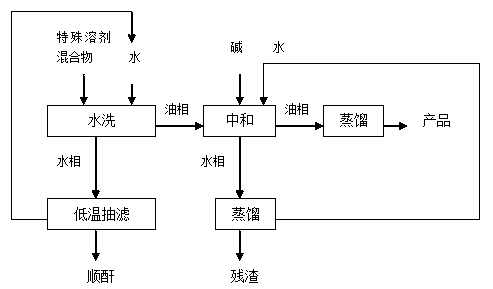

Embodiment 1

[0017] Add 200ml of xylene, 13ml of dimethyl sulfoxide mixture and 160ml of water to 538g of 37.27% N-PMI reaction solution, stir at 102°C for 30min, wait for the temperature to cool to 60°C, pour 1000ml of liquid separation Layers in the funnel. When the separated aqueous phase was cooled to 20°C, it was suction-filtered in a sand core funnel with a pore size of G3 to obtain 27.4 g of 92.3% maleic anhydride solid. Pour the separated oil phase into a four-neck flask to heat, add 100g of 10% Na at 80°C 2 CO 3 Neutralize until the pH is 7, separate layers when cooled to 42°C, take the neutralized water phase for distillation, and spin the neutralized oil phase under a vacuum of -0.094Mpa to stop heating when the liquid temperature is 110°C to obtain 374.8 g solvent and 197g content are 99.25% N-PMI product, and the aftertreatment yield is 97.5%.

Embodiment 2

[0019] The operating conditions are the same as in Example 1. When washing with water, 13ml of dimethyl sulfoxide is changed to 20ml of dimethylformamide, added to 527.9g of 40% N-PMI reaction solution, stirred at 70°C for 5min, and cooled to 72°C at the same temperature When the mixture was poured into a 1000ml separatory funnel to separate layers, the rest of the conditions remained unchanged. 29.6g of 90.9% maleic anhydride solid, 380.2g of solvent and 208g of N-PMI product with a content of 99.19% were obtained, and the post-treatment yield was 97.7%.

Embodiment 3

[0021] The operating conditions are the same as in Example 1. When washing with water, 200ml of xylene is changed to 180ml of toluene and added to 529.5g of 43.3% N-PMI reaction solution, and the neutralized oil phase is subjected to spin liquid distillation at a vacuum of -0.098Mpa. The remaining conditions constant. 28.1 g of 93.5% maleic anhydride solid, 370.6 g of solvent and 226 g of N-PMI product with a content of 99.48% were obtained, and the post-treatment yield was 98.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com