Process for circulation strengthening extraction of high purity copper powder by using copper scrap

A technology of waste miscellaneous copper and copper powder, applied in the direction of improving process efficiency, etc., can solve the problems of solution volume expansion, large acid consumption, low copper powder yield, etc., to achieve the promotion of reaction efficiency, strong oxidation ability, and equipment size small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

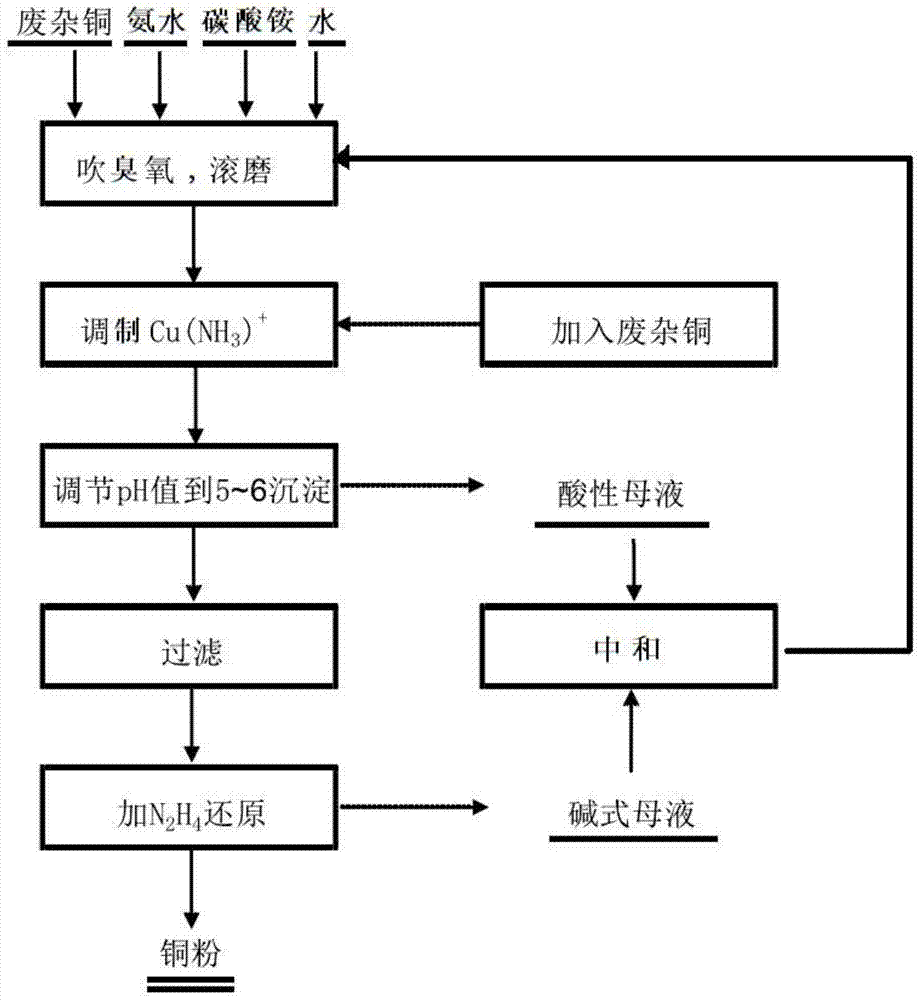

Method used

Image

Examples

Embodiment 1

[0023] 1) Taking the copper content of scrap copper, concentrated ammonia water, ammonium carbonate, and water as raw materials, take 10 kg of scrap copper (including 2 kg of copper), 10 liters of concentrated ammonia water, 10 kg of ammonium carbonate, and 50 liters of water, and put them into In the drum type ball mill, add a corresponding amount of iron balls according to the weight ratio of scrap copper raw materials and iron balls to 1:0.5, start the ball mill, and the speed is between 50rpm;

[0024] (2) Introduce ozone into the immersion liquid of the above ball mill at a speed of 6m 3 / h;

[0025] (3) After running the above leaching system for 30 hours, stop the introduction of ozone, add 10 kg of waste miscellaneous copper materials, continue to run and start heating reaction for 5 hours, quickly filter while hot, and transfer the mother liquor to an enamel reaction kettle in, and start stirring;

[0026] (4) Add 1mol / L sulfuric acid solution to the mother liquor, ...

Embodiment 2

[0028] 1) Taking the copper content of scrap copper, concentrated ammonia water, ammonium carbonate, and water as raw materials, take 10 kg of scrap copper (including 2 kg of copper), 15 liters of concentrated ammonia water, 5 kg of ammonium carbonate, and 150 liters of water, and put them into In the drum type ball mill, add a corresponding amount of iron balls according to the weight ratio of scrap copper raw materials to iron balls is 1:0.8, start the ball mill, and the speed is between 80rpm;

[0029] (2) Introduce ozone into the immersion liquid of the above ball mill at a speed of 10m 3 / h;

[0030] (3) After running the above leaching system for 18 hours, stop the introduction of ozone, add 12 kg of waste miscellaneous copper materials, continue to run and start heating reaction for 3 hours, quickly filter while hot, and transfer the mother liquor to an enamel reaction kettle in, and start stirring;

[0031] (4) Slowly add sulfuric acid solution with a concentration o...

Embodiment 3

[0033] 1) Taking the copper content of scrap copper, concentrated ammonia water, ammonium carbonate, and water as raw materials, take 10 kg of scrap copper (including 2 kg of copper), 10 liters of concentrated ammonia water, 5 kg of ammonium carbonate, and 100 liters of water, and put them in In the drum type ball mill, add a corresponding amount of iron balls according to the weight ratio of scrap copper raw materials and iron balls to 1:1, start the ball mill, and the speed is between 100rpm;

[0034] (2) Introduce ozone into the immersion liquid of the above ball mill at a speed of 15m 3 / h;

[0035] (3) After running the above leaching system for 10 hours, stop the introduction of ozone, add 10 kg of waste miscellaneous copper materials, continue to run and start heating reaction for 3 hours, quickly filter while hot, and transfer the mother liquor to an enamel reaction kettle in, and start stirring;

[0036] (4) Slowly add 1mol / L sulfuric acid solution to the mother liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com