Industrial wastewater treatment method

A treatment method and technology for industrial wastewater, applied in water/sewage multi-stage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of unsatisfactory desorption effect, affecting membrane service life, Insufficient desorption effect, etc., to achieve the effect of excellent desorption effect, efficient removal and improvement of desorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The treatment device and treatment method in the present invention are mainly aimed at the phenol cyanide wastewater, including the effluent of the biochemical treatment system, the concentrated brine from the desalination station, the coke oven gas desulfurization waste liquid from the coke oven gas desulfurization waste liquid, and the salt solution after neutralization by wet acid production (2% dilute sulfuric acid through NaOH) neutralization), but not limited to these ranges. The percentages involved in the present invention are all mass percentages.

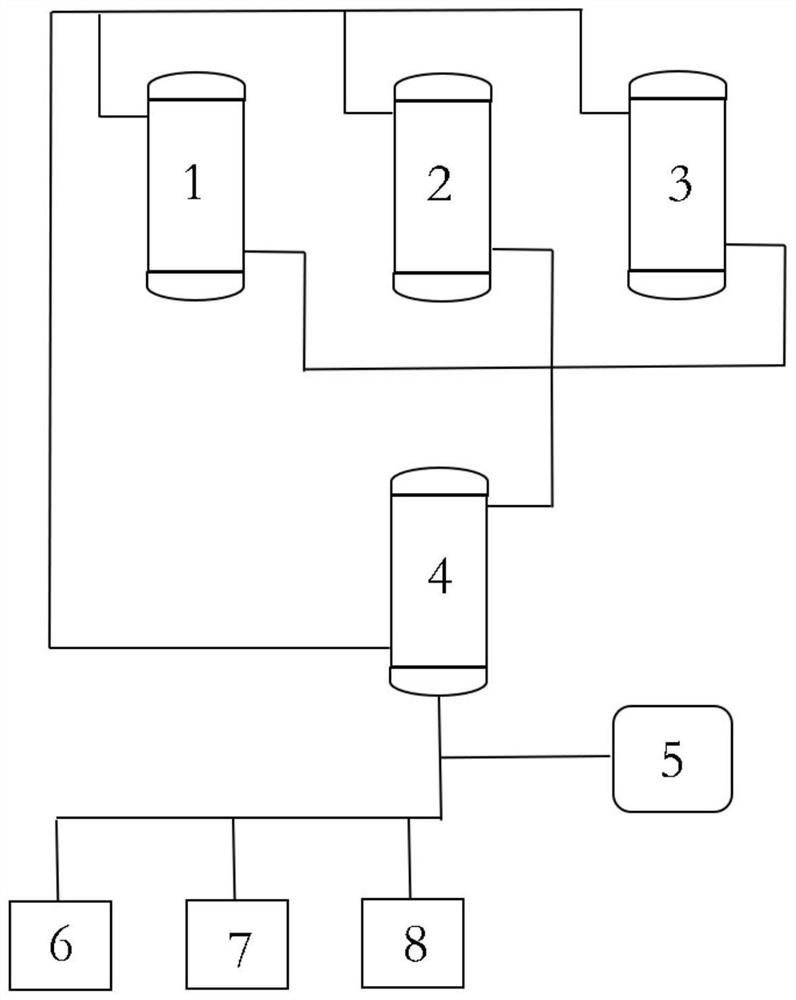

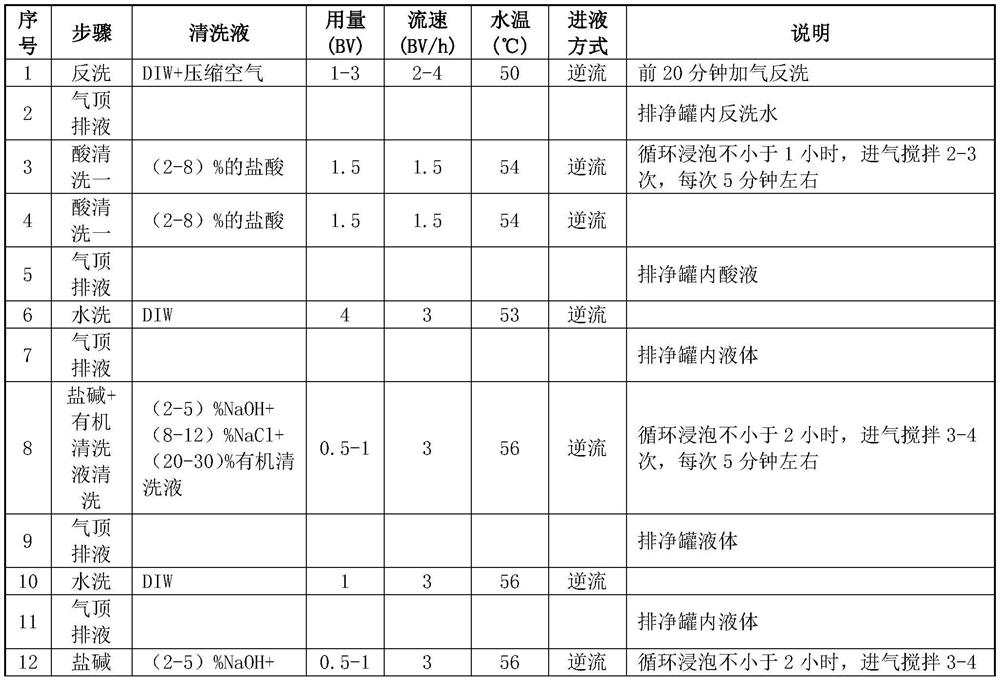

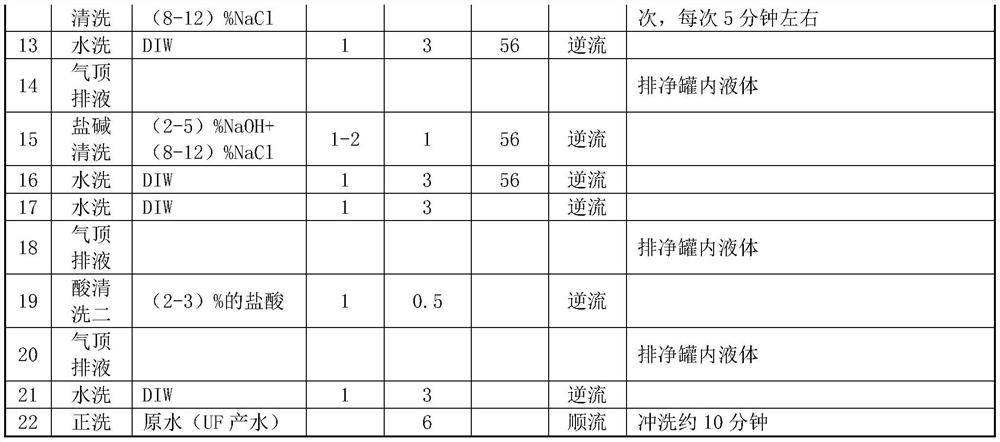

[0031] A method of industrial wastewater treatment, such as figure 1 As shown, the adopted device includes three parallel adsorption tanks (adsorption tank one 1, adsorption tank two 2, adsorption tank three 3), and a desorption tank 4 connected with the three adsorption tanks through the resin transfer pipe, and the three adsorption tanks Two of the tanks work alternately, and the third is for standby. The desorpt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com