Device for recovering oil and gas by condensation-adsorption method

A technology of recovery device and adsorption method, which is applied in the direction of distribution device, special distribution device, liquid distribution, transportation or transfer device, etc. It can solve the problems of unsatisfactory economic indicators and technical performance, affecting desorption effect, poor cooling effect, etc. Achieve high vacuum level, enhanced cooling effect, and improved life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

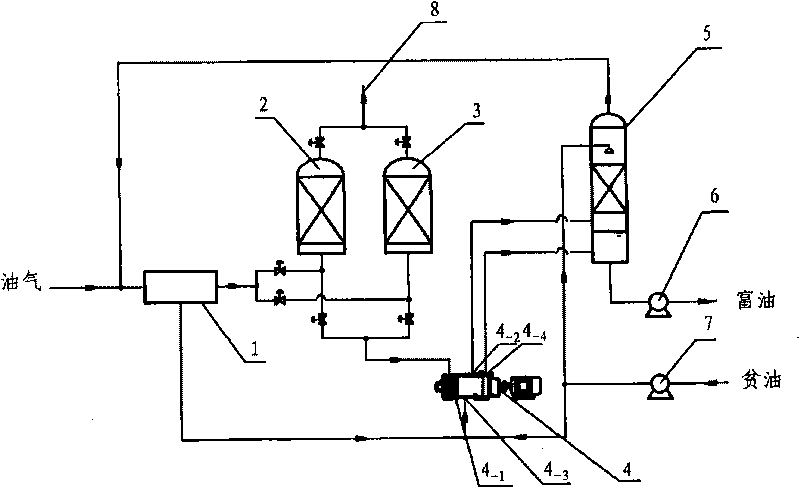

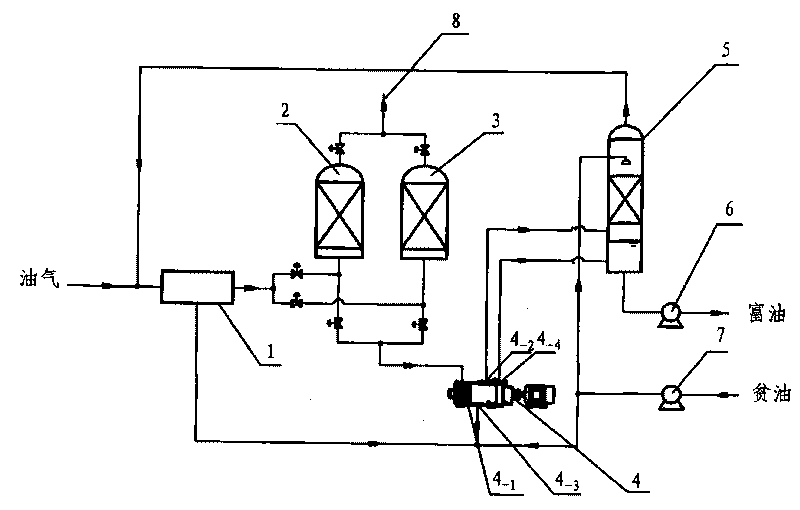

[0017] Such as figure 1 As shown, the present invention is a kind of oil gas recovery device utilizing the condensation adsorption method, the device comprises a heat exchanger 1, an adsorber 2, an adsorber 3, a dry vacuum pump 4, an absorption tower 5, a rich oil pump 6, a lean oil pump 7, The air exhaust pipe 8 is characterized in that: the left end of the heat exchanger 1 has an oil and gas inlet, and the right end has an oil and gas outlet, and the oil and gas outlet is connected to the bottom of the adsorber 2 and the adsorber 3 through the pipeline, and the bottom of the heat exchanger is connected to the dry vacuum pump 4 oil inlet 4 -3 Connected by pipes, the bottoms of the two adsorbers are respectively connected to the oil and gas inlet of the dry vacuum pump through pipes 4 -1 connected, and the upper parts of the two adsorbers are respectively connected to the exhaust pipe 8 through pipes, and the oil and gas outlet 4 of the dry vacuum pump 4 -2 and oil outlet 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com