Process for adsorbing, desorbing and catalytically oxidizing VOCs by using activated carbon in pharmaceutical industry

A technology of activated carbon adsorption and catalytic oxidation, applied in chemical instruments and methods, gas treatment, membrane technology, etc., can solve the problems of high investment and operating costs, heavy device weight, long heating time, etc., to reduce operating costs and reduce manufacturing Cost, the effect of increasing the design airspeed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

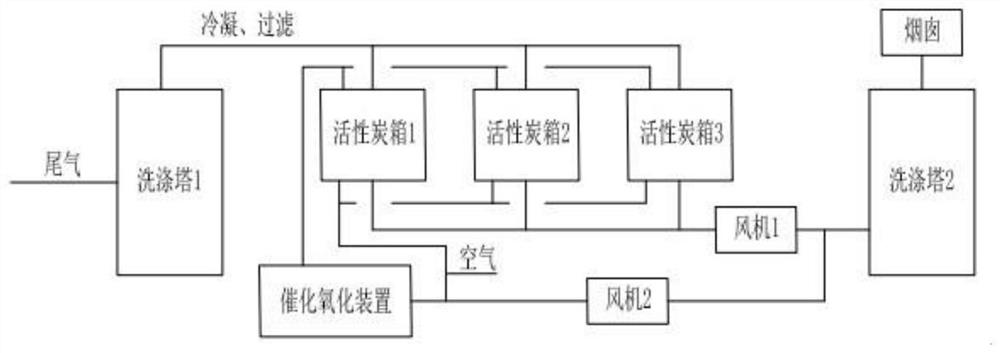

[0016] like figure 1 As shown, a process for activated carbon adsorption and desorption catalytic oxidation of VOCs in the pharmaceutical industry, including an alkali washing tower group, an activated carbon group, a catalytic oxidation device, and a fan; the activated carbon group includes a first activated carbon box, a second activated carbon box, and a third activated carbon box. The upper part of the activated carbon group is connected to the inlet pipe, and the lower part is connected to the outlet pipe. The activated carbon group is connected to the catalytic oxidation device through a branch pipe to form a circular loop; the catalytic oxidation device is equipped with a catalyst, which uses porous thin-walled honeycomb ceramics. As a carrier, a layer of nano-active alumina and a layer of Pt metal-modified nano-scale material H are sequentially loaded on its surface 2 Pt(OH) 6 The catalyst comprises the following components in mass percentage: nano H2Pt (OH) 6 account...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com