Poly-p-xylene surface coating equipment of ancient books and literatures and its coating technology

A technology of parylene and coating equipment, which is applied to the surface coating liquid device, metal material coating process, coating, etc., which can solve the problems of short life, high cost, and low repair rate, and achieve Guaranteed uniformity and consistency, volume-boosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

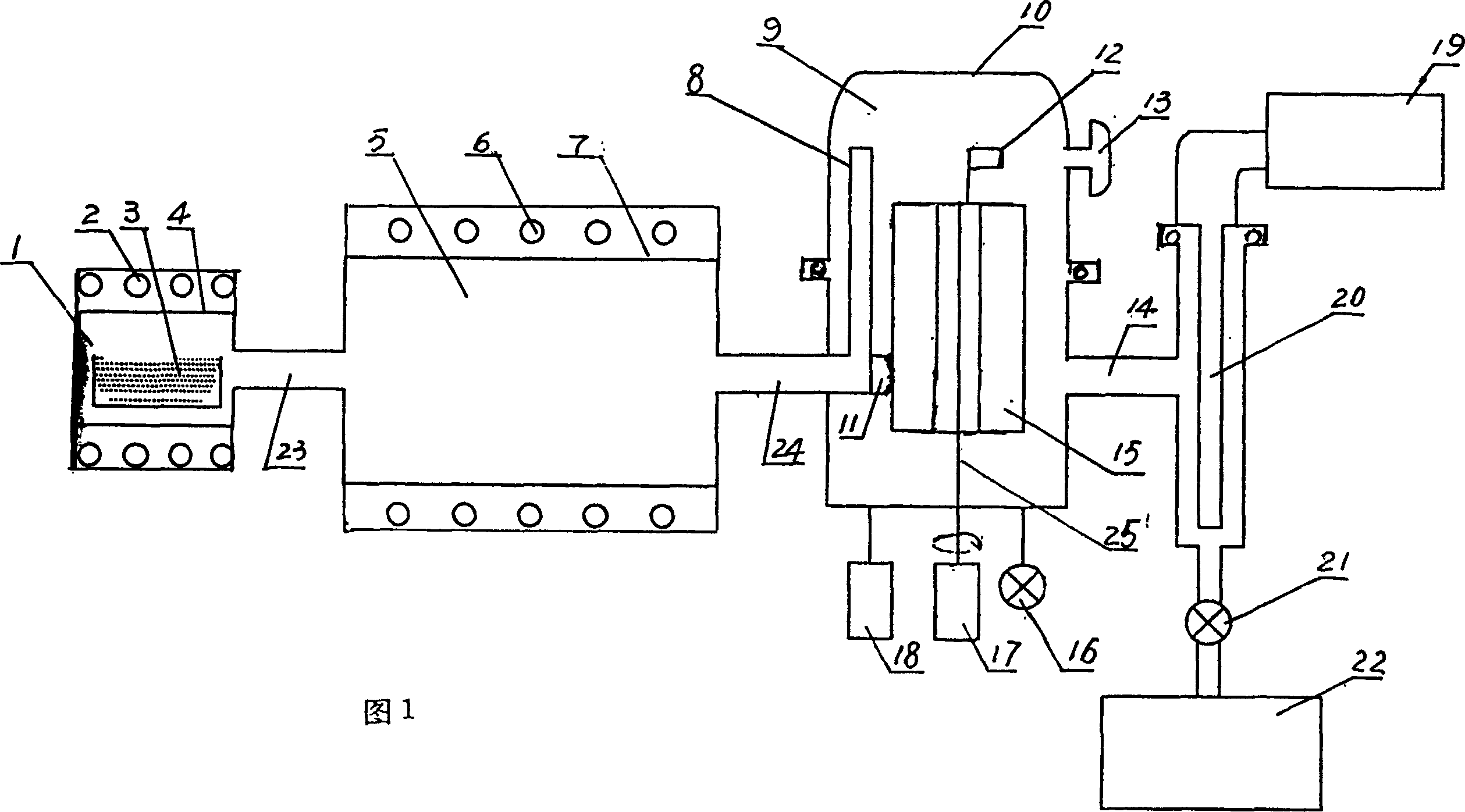

[0035] The parylene surface coating process of ancient books and documents includes the following steps:

[0036] 1. Put the p-xylene raw material in the evaporation boat in the evaporation chamber;

[0037] 2. Clamp the books or documents to be coated on the book expansion bracket in the polymerization deposition chamber, and close the vacuum bell jar;

[0038] 3. Open the throttle valve, turn on the vacuum mechanical pump, and evacuate the system to make the vacuum degree of the system below 10pa;

[0039] 4. Raise the temperature of the cracking chamber to 600°C, open the cold trap, and make the temperature of the cold trap below -80°C, and then heat the evaporation chamber to steadily increase the temperature of the evaporation chamber to 120°C. When the temperature of the evaporation chamber exceeds 90°C, adjust the throttle valve The pumping speed is to keep the vacuum degree of the sedimentation chamber at 20pa. At the same time, start the transmission motor to make th...

Embodiment 2

[0046] The parylene surface coating process of ancient books and documents includes the following steps:

[0047] 1. Put the p-xylene raw material in the evaporation boat in the evaporation chamber;

[0048] 2. Clamp the books or documents to be coated on the book expansion bracket in the polymerization deposition chamber, and close the vacuum bell jar;

[0049] 3. Open the throttle valve, turn on the vacuum mechanical pump, and evacuate the system to make the vacuum degree of the system below 10pa;

[0050] 4. Raise the temperature of the cracking chamber to 700°C, open the cold trap, and make the temperature of the cold trap below -80°C, and then heat the evaporation chamber to steadily increase the temperature of the evaporation chamber to 125°C. When the temperature of the evaporation chamber exceeds 90°C, adjust the throttle valve The pumping speed is to keep the vacuum degree of the precipitation chamber at 40pa, and at the same time start the transmission motor to make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com