Method for efficiently extracting V/W/Ti from waste denitration catalyst

A waste denitration catalyst and alkali leaching technology, applied in the direction of titanium oxide/hydroxide, titanium dioxide, process efficiency improvement, etc., can solve the problems of secondary pollution of heavy metals, inability to achieve high recovery rate at the same time, waste of resources, etc. The effect of permeability, avoiding acid-base consumption and reducing cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

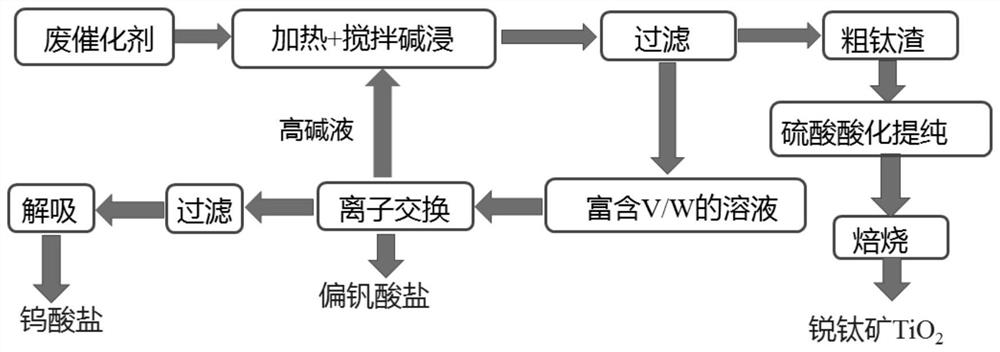

Method used

Image

Examples

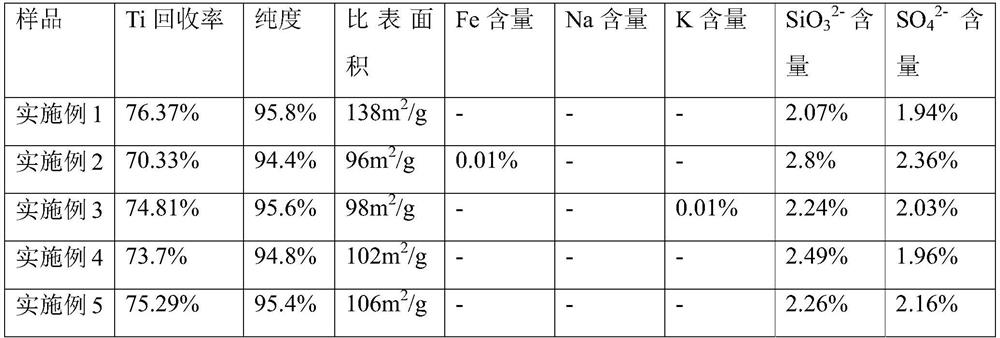

Embodiment 1

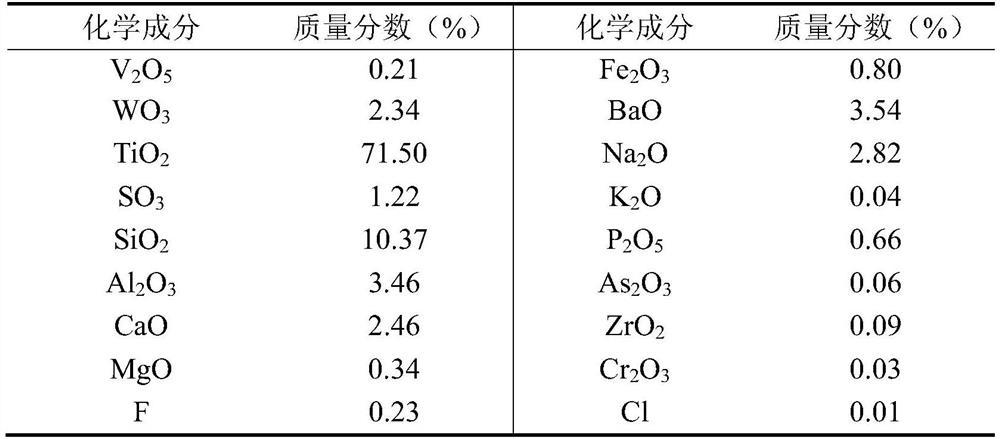

[0045] (1) The waste denitration catalyst is soot-blown, washed with water, ground, and passed through a 120-mesh sieve.

[0046] (2) Weigh 100g of the sieved sample and place it in an autoclave, add 120g of NaOH solution with a mass fraction of 30% and a stirring bar, heat up to 100°C, stir at 700r / min for 3h, and cool to room temperature After filtration, leachate and filter cake were obtained, and the filter cake was dried at 100° C. for 12 hours to obtain coarse titanium slag.

[0047] (3) Pass 100mL of the leachate obtained in step (2) into a glass tube containing 50g of polypropylene fiber, and exchange at a constant temperature of 25°C for 1h to obtain VO-rich 3 - The effluent and adsorbed WO 4 2- ionic fibers. Rich in VO to 100g 3 - Add 4.17g ammonium chloride in the effluent liquid, filter to obtain product ammonium metavanadate.

[0048] (4) the adsorption WO obtained in step (3) 4 2- 250mL, 2mol / L NH 4 Cl and 1mol / LNH 3 ·H 2 The desorption solution of O ...

Embodiment 2

[0053] (1) The waste denitration catalyst is soot-blown, washed with water, ground, and passed through a 120-mesh sieve.

[0054] (2) Weigh 100g of the sieved sample and place it in an autoclave, add 100g of NaOH solution with a mass fraction of 20% and a stirring bar, heat up to 60°C, stir at 750r / min for 3h, and cool to room temperature After filtration, leachate and filter cake were obtained, and the filter cake was dried at 100° C. for 12 hours to obtain coarse titanium slag.

[0055] (3) Put 100mL of the leaching solution obtained in step (2) into a glass tube containing 71.4g of polypropylene fibers, and exchange at a constant temperature of 25°C for 0.5h to obtain VO-rich 3 - The effluent and adsorbed WO 4 2- ionic fibers. Enriched with VO to 100g 3 - Add 7.14g ammonium chloride in the effluent liquid, filter to obtain product ammonium metavanadate.

[0056] (4) the adsorption WO obtained in step (3) 4 2- The ionic fiber uses 85.7mL, 1mol / L NH 4 Cl and 0.5mol / ...

Embodiment 3

[0061] (1) The waste denitration catalyst is soot-blown, washed with water, ground, and passed through a 120-mesh sieve.

[0062] (2) Weigh 100g of the sieved sample and place it in an autoclave, add 80g of NaOH solution with a mass fraction of 40% and a stirring bar, heat up to 200°C, stir at 700r / min for 9h, and cool to room temperature After filtration, leachate and filter cake were obtained, and the filter cake was dried at 100° C. for 12 hours to obtain coarse titanium slag.

[0063] (3) Pass 50mL of the leach solution obtained in step (2) into a glass tube containing 10g of polyvinyl alcohol fibers, and exchange at a constant temperature of 30°C for 12h to obtain VO-rich 3 - The effluent and adsorbed WO 4 2- ionic fibers. Enriched with VO to 50g 3 - Add 1g ammonium chloride in the effluent liquid, filter to obtain product ammonium metavanadate.

[0064] (4) the adsorption WO obtained in step (3) 4 2- 30mL, 3mol / L NH 4 Cl and 3mol / LNH 3 ·H 2 The desorption sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com