Motorcycle fuel evaporative pollutant control system

A technology for controlling system and pollutants. It is applied in the direction of charging system, adding non-fuel substances to fuel, engine components, etc. It can solve the problems of inability to ensure effective desorption of fuel vapor in the carbon tank, affecting discharge under working conditions, and insufficient negative pressure, etc. problems, to achieve the effect of saving processing hours, improving quality and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

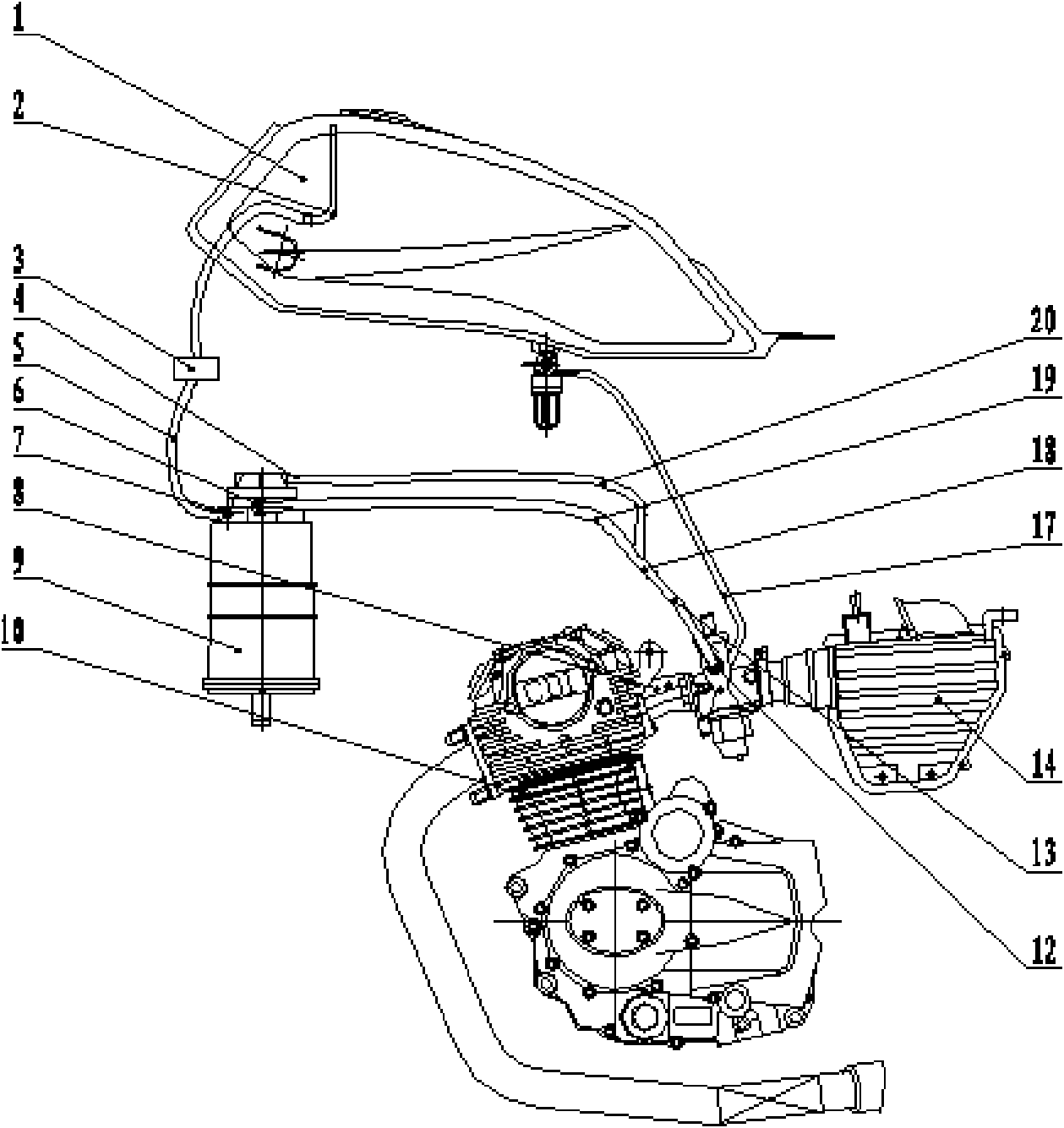

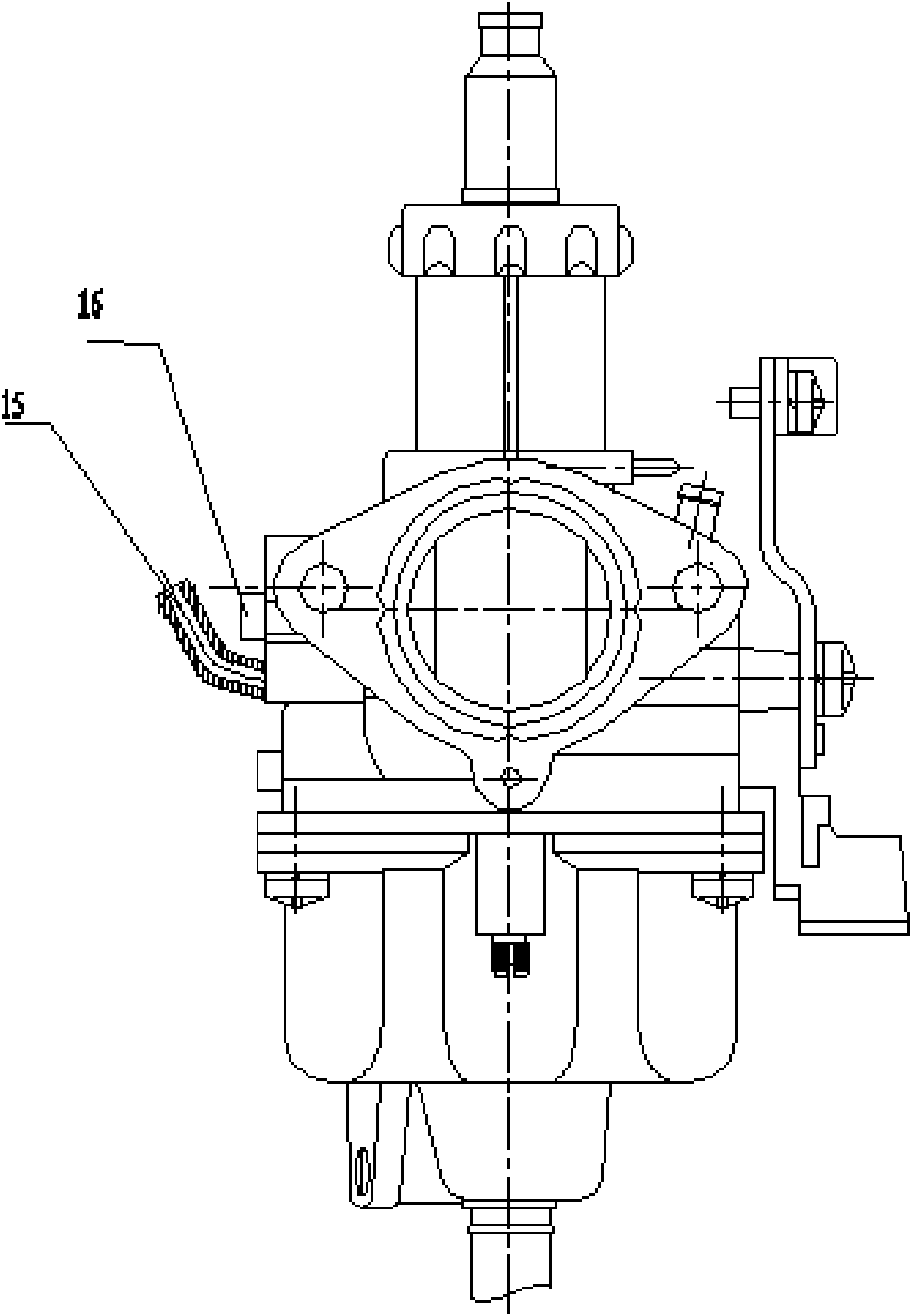

[0015] Such as figure 1 As shown, the carbon canister 9 adopts a canister with a storage volume of 200ml to ensure that it has sufficient adsorption capacity, and the mass of normal adsorbed fuel vapor is about 20 grams. The intake adsorption port 7 of the carbon canister 9 is connected to the fuel tank vent pipe 2 through the fourth pipeline 5, the gasoline shut-off valve 3 is installed on the fourth pipeline 5, and the pressure control valve 4 of the carbon canister 9 is connected to the fuel tank vent pipe 2 through the second pipeline 20. The three-way pipe 18 is connected to one port, and the gas outlet and desorption port 6 of the carbon tank 9 is connected to the other port of the three-way pipe 18 through the first pipeline 19. After the third pipe 13 is connected to the third port of the three-way pipe 18 The air passages of the carburetor 12 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com