Polluted gas adsorption and desorption equipment and method

A pollution gas, adsorption and desorption technology, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of not widely used regenerative adsorbent, secondary pollution, long heating time, etc., to improve regeneration efficiency and repeatability. The ability to adsorb polluted gases, uniform and rapid heating, and the effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0031] In the present invention, unless stated otherwise, the used orientation words such as "upper, lower, top, bottom" usually refer to the orientation shown with reference to the drawings. "Inner and outer" refer to inner and outer relative to the outline of each component itself.

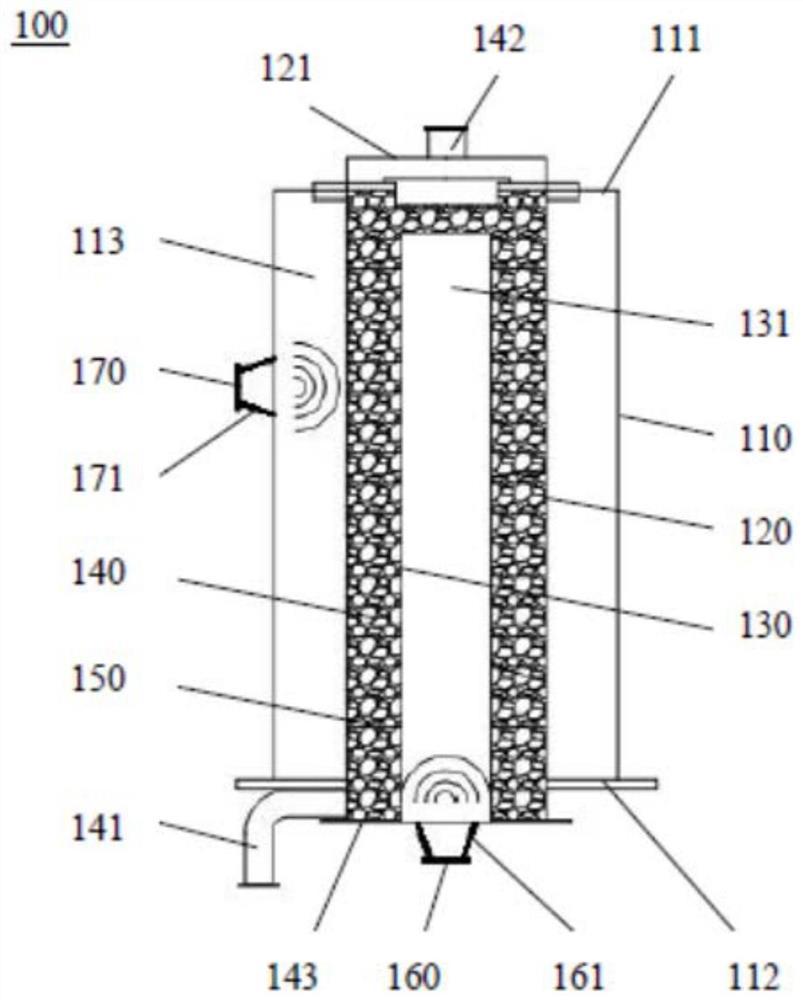

[0032] One aspect of the present invention provides a pollution gas adsorption and desorption device, the pollution gas adsorption and desorption device 100 includes a housing assembly, a first microwave generator 160 and a second microwave generator 170, and the housing assembly includes an annular adsorption channel 140 and a first opening and a second opening communicating wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com