Reverse osmosis seawater desalination pretreatment device

A pretreatment device and reverse osmosis technology, applied in seawater treatment, osmosis/dialysis water/sewage treatment, multi-stage water treatment, etc., can solve problems such as insufficient activated carbon adsorption, damage to reverse osmosis components, and troublesome filter cleaning. , to achieve the effect of saving manpower, thorough adsorption treatment, and avoiding adsorption dead corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

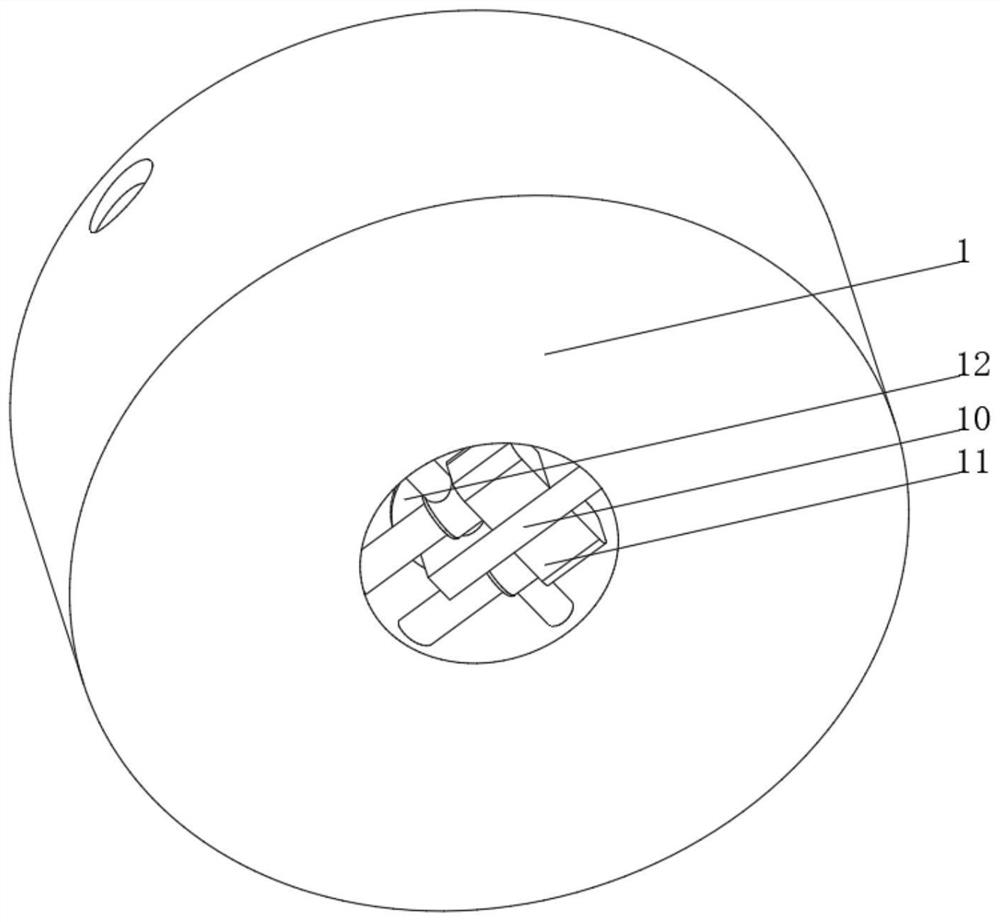

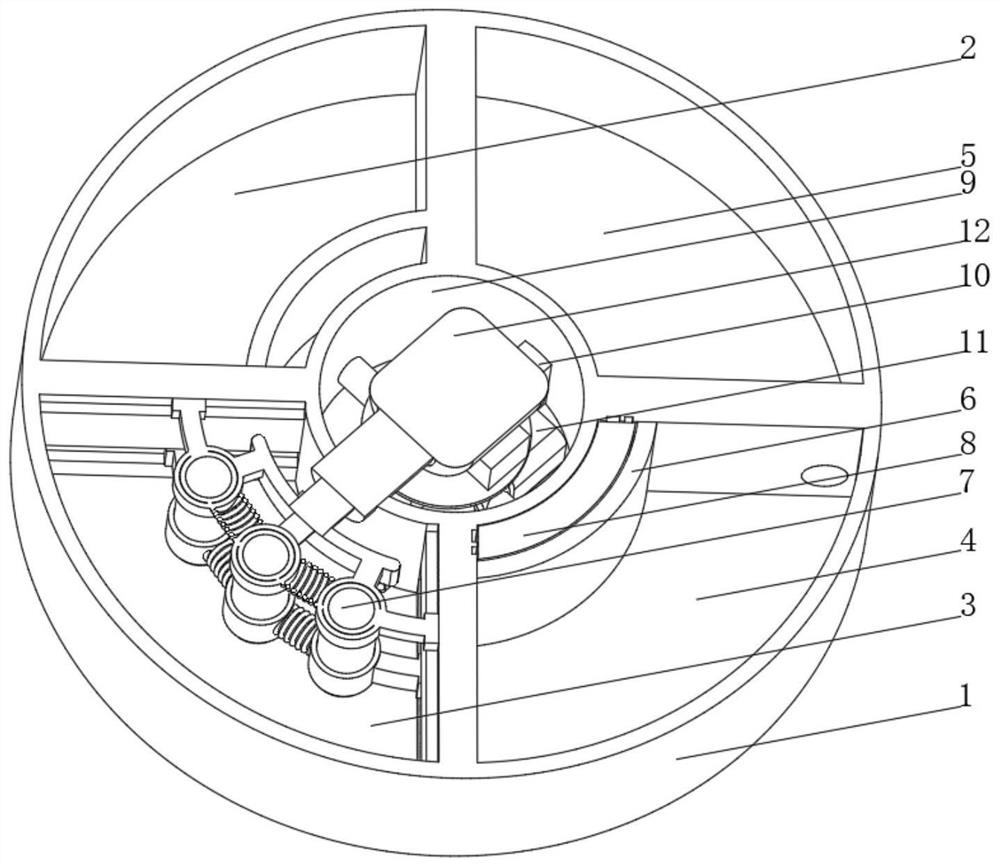

[0037] see Figure 1-3 , the present invention provides a technical solution: a reverse osmosis seawater desalination pretreatment device, specifically comprising:

[0038] A treatment box 1 is provided with a rough filter space 2, an adsorption space 3, a fine filter space 4, and a discharge space 5 in sequence in the treatment box 1, and the rough filter space 2 and the fine filter space 4 are both provided with an arc-shaped filter screen 6, and the adsorption An adsorption device 7 is arranged inside the space 3;

[0039] A cleaning device 8, the cleaning device 8 is arranged inside the fine filter space 4, and one side of the cleaning device 8 is closely attached to the curved filter screen 6 inside the fine filter space 4;

[0040] Control space 9, the control space 9 is set at the center position inside the processing box 1, the inner wall of the control space 9 is fixedly connected with a positioning plate 10, both sides of the positioning plate 10 are fixedly connect...

Embodiment 2

[0045] see Figure 1-4 On the basis of Embodiment 1, the present invention provides a technical solution: the cleaning device 8 includes an arc-shaped sliding plate 81, the top of the arc-shaped sliding plate 81 is fixedly connected to the top of the inner wall of the fine filter space 4 through a return spring 82, and the two ends of the arc-shaped sliding plate 81 Both of them are fixedly connected to the limit slide bar 83, and one side of the curved slide plate 81 is fixedly connected with a cleaning brush 84, and a cleaning device 8 is provided. The mesh of the filter screen inside the filter space 4 is small, and the resistance to water is relatively large. When the water pump 11 sends water to the inside of the fine filter space 4, the water pressure on the side of the filter screen on the inner wall of the fine filter space 4 near the cleaning device 8 increases gradually. Push the cleaning brush 84 inside the cleaning device 8 to move upwards. After the fine filtratio...

Embodiment 3

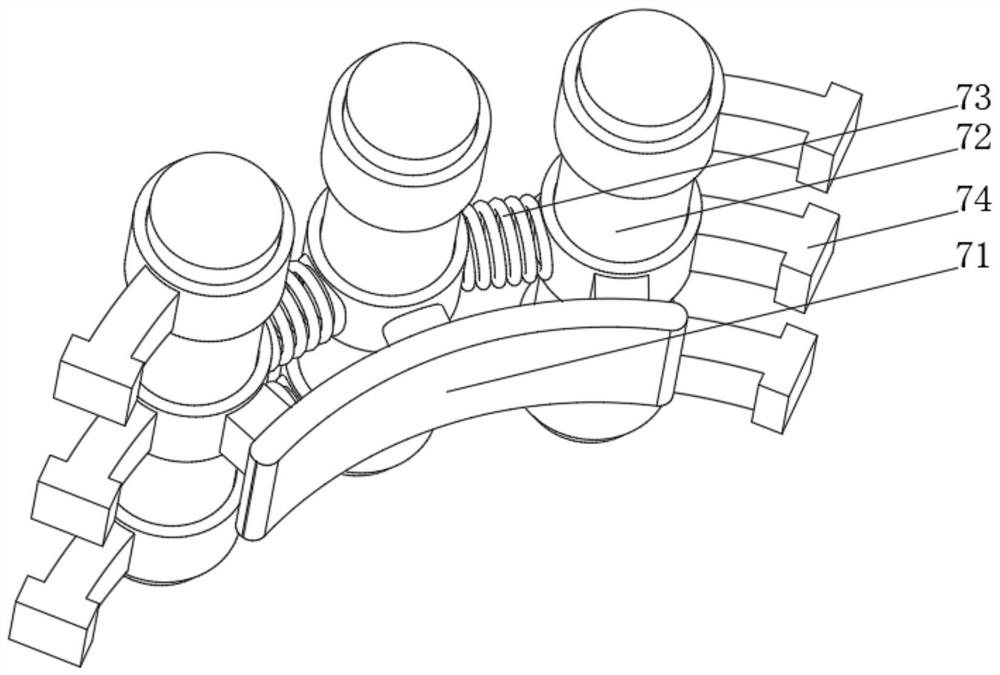

[0047] see Figure 1-5 On the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the cleaning brush 84 includes a fixed frame 841, the bottom of the inner wall of the fixed frame 841 is fixedly connected with a fixed brush 842, and the inner wall of the fixed frame 841 is located at the bottom of the fixed brush 842. Part of the rotation is connected with a rotating brush 843, and the two ends of the rotating brush 843 run through the fixed frame 841 and are fixedly connected with a rotating gear 844. Adapted to the tooth groove, the rotating gear 844 extends to the inside of the tooth groove and engages with the inner wall of the tooth groove. There are multiple groups of rotating brushes 843 connected by rubber shafts. A cleaning brush 84 is provided, and a rotating brush 843 is arranged inside the cleaning brush 84 , when the cleaning brush 84 moves up and down, it can drive the rotating gear 844 to rotate through the tooth groove i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com