Non-methane total hydrocarbon detection system and method based on single valve

A non-methane total hydrocarbon detection system technology, which is applied in the field of non-methane total hydrocarbon detection system based on single valve, can solve the problems of difficult synchronization of valve switching, inaccurate analysis data, and the need for multi-channel carrier gas. Avoid the loss of analytical accuracy, accurate analytical data, and reduce the effect of chromatographic peak broadening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

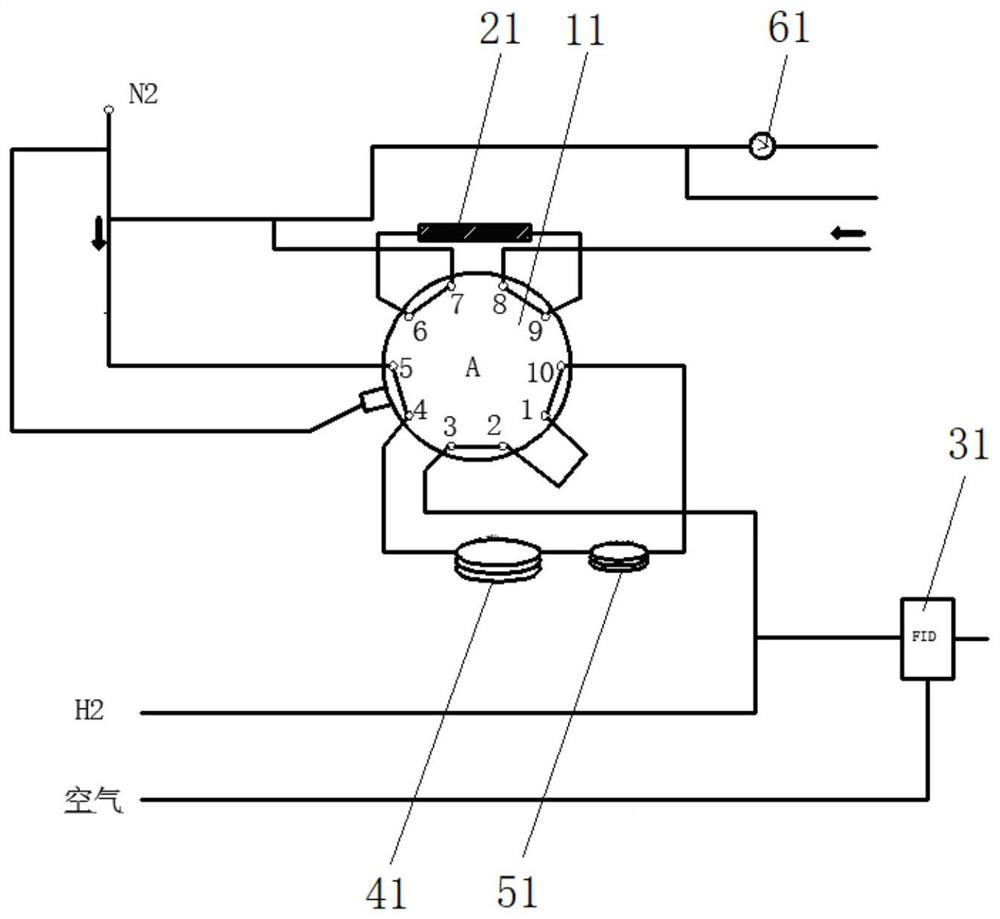

[0032] figure 1 A schematic structural diagram of a non-methane total hydrocarbon detection system based on a single valve in an embodiment of the present invention is given, as figure 1 As shown, the non-methane total hydrocarbon detection system based on single valve comprises:

[0033] Quantitative loop 21, chromatographic column 41 and detector 31, these parts all are prior art;

[0034] A multi-way valve 11, such as a ten-way valve, the only port of the multi-way valve 11 is respectively connected to the two ends of the quantitative loop 21, the two ends of the chromatographic column 41, the sample gas, the carrier gas and the detector 31; The carrier gas is selectively connected to one end of the quantitative loop 21 and one end of the chromatographic column 41, and the other end of the quantitative loop 21 is selectively connected to the sample gas and the other end of the chromatographic column 41;

[0035] Adsorption tube 51, the adsorption tube 51 is connected in s...

Embodiment 2

[0046] An application example of the non-methane total hydrocarbon detection system and method based on a single valve according to Embodiment 1 of the present invention.

[0047] In this application example, if figure 1 As shown, the chromatographic column 41 is a PQ column, and the adsorption tube 51 is filled successively with Tenax (adsorbing low boiling point substances) with strong adsorption capacity and Carbalsleve (adsorbing high boiling point substances) with weak adsorption capacity; Through valve; Detector 31 adopts FID;

[0048] The adsorption tube is made of an inertized metal tube. The external power supply is connected to both ends of the adsorption tube, and the heating is directly energized, which significantly increases the heating rate.

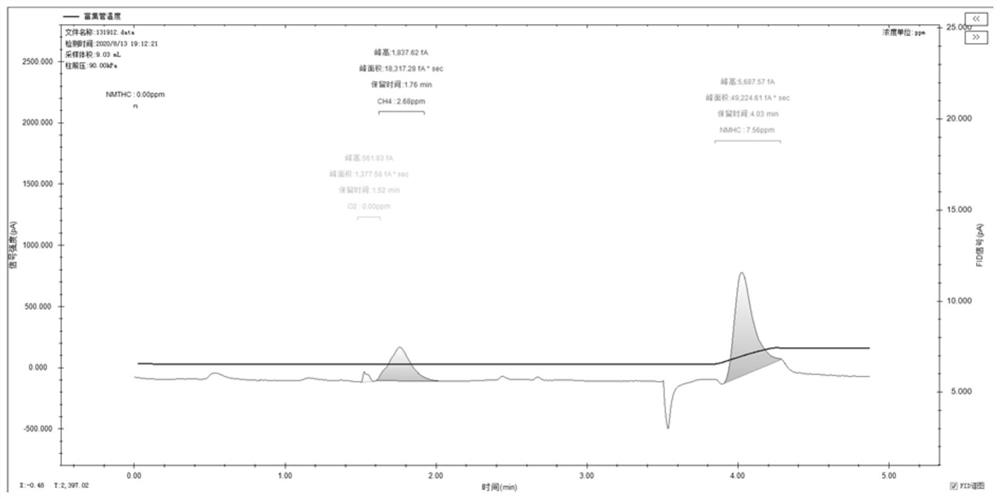

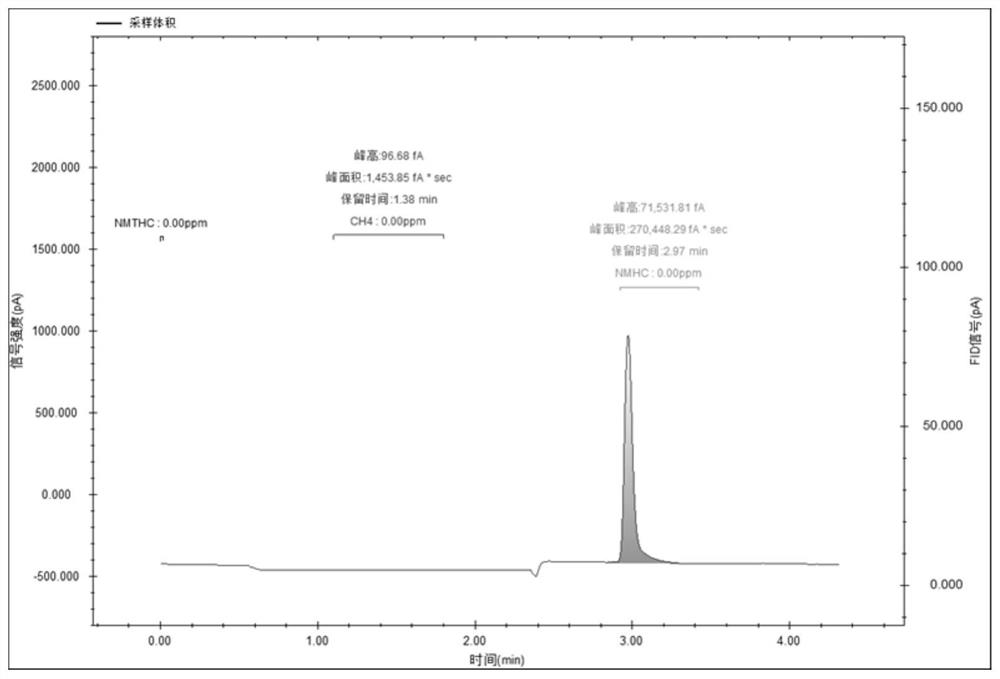

[0049] The non-methane total hydrocarbon detection method based on a single valve in the embodiment of the present invention, that is, the working method of the detection system of this embodiment, the single-valve-based ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com