Method and device for reducing regeneration energy consumption of decarburization absorption liquid

A technology of absorbing liquid and decarbonization, which is applied in the field of energy saving and environmental protection, can solve the problems of reducing the energy consumption of absorbing liquid regeneration, and achieve the effects of saving decarbonization operating costs, reducing heating energy consumption, and reducing the amount of rich liquid regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

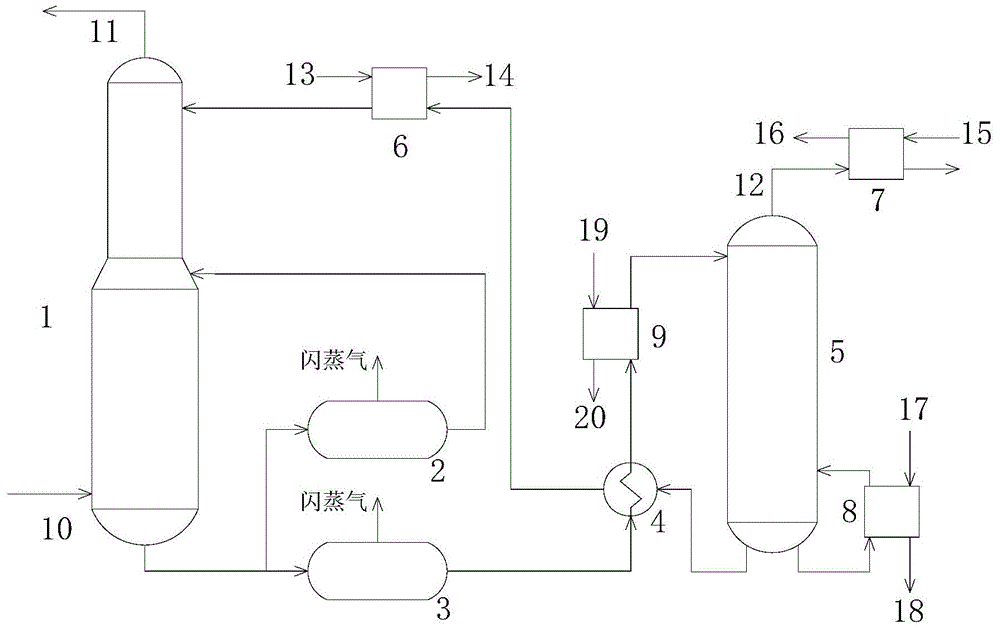

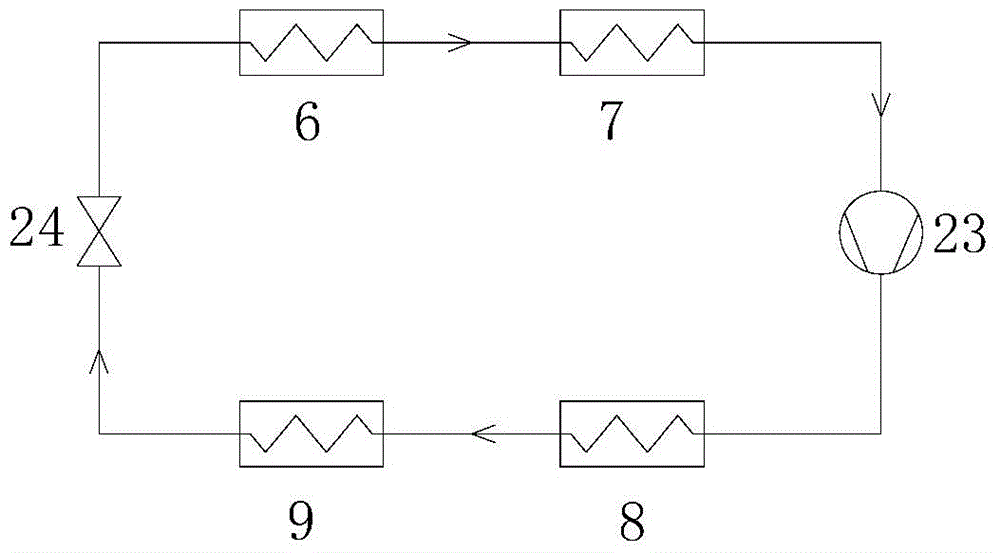

[0034] Such as figure 1 The method and device for reducing the regeneration energy consumption of the decarburization absorption liquid of the present invention shown in the present invention, the gas to be purified enters the absorption tower 1 from the gas inlet 11 to be purified, and the operating pressure in the tower is 4MPa, and the gas is discharged from the purified gas outlet 11 after purification, Activated MDEA decarbonization absorption tower absorbs CO in sufficient contact 2 The activated MDEA solution (rich liquid) flows out from the bottom of the tower, and 3 / 5 of the rich liquid flow (rich liquid A) enters the first flash tank 2, and the CO absorbed in the solution at normal pressure (local atmospheric pressure) 2 After desorption, the flash liquid is subjected to low-density ultrasonic waves at the outlet of the first flash tank after flash desorption, and the ultrasonic working time is 2 seconds. 2 . The remaining 2 / 5 rich liquid (rich liquid B) enters the...

Embodiment 2

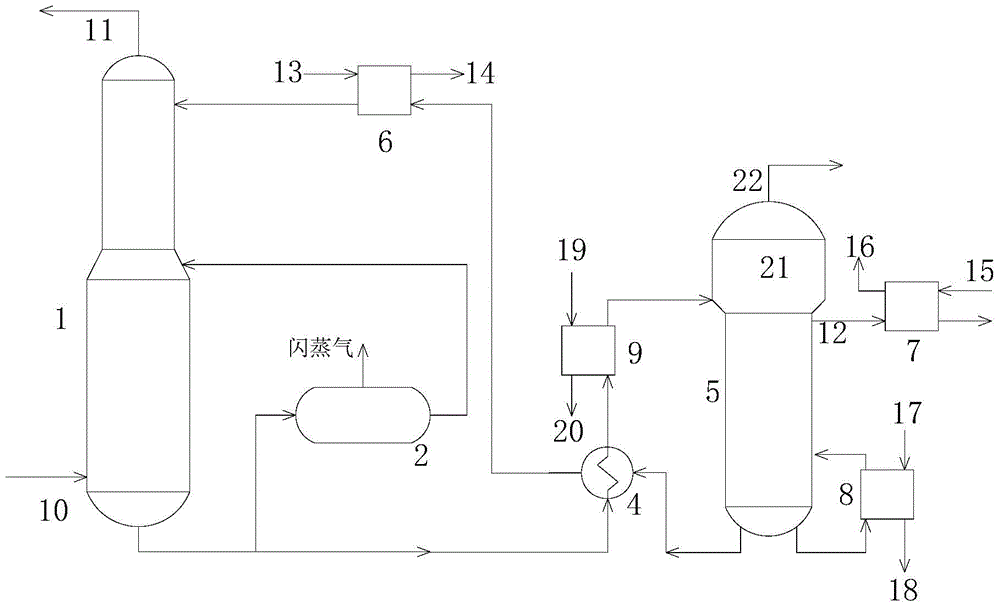

[0036] This embodiment is basically the same as Embodiment 1, the difference is: as figure 2 , 1 / 3 of the rich liquid (rich liquid A) applies low-density ultrasound to the flash liquid after flash desorption in the first flash tank, and the ultrasonic working time is 30 seconds; 2 / 3 of the rich liquid (rich liquid C) does not pass through the first flash tank The second flash tank decompresses and flashes, and directly enters the desorption device 21 installed on the top of the regeneration tower after being heated by a heat exchanger and a heat pump. In this device, the rich liquid releases a large amount of acid gas and is discharged through the desorption gas outlet 22. The diameter of the device is 1.1 times the diameter of the regeneration tower, and the bottom of the device communicates with the main body of the regeneration tower.

Embodiment 3

[0038] This embodiment is basically the same as Embodiment 2, except that the desorption device installed at the top of the regeneration tower has a diameter of 1.5 times the diameter of the regeneration tower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com