Flue gas absorbent of desulfurization and denitrification, and desulfurization and denitrification method thereof

A technology for desulfurization, denitrification, and flue gas, which is applied in the field of flue gas purification, can solve problems affecting fertilizer quality, etc., and achieve the effects of rapid desorption, high desulfurization and denitrification rate, and low desorption energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

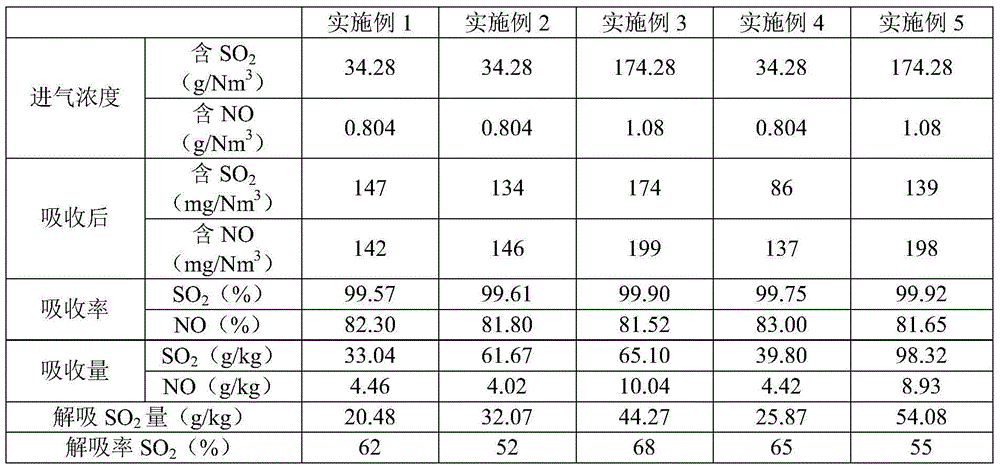

Examples

Embodiment 1

[0018] 70 grams of absorption component ethylpiperazine, 2 grams of activation component diazabicyclo, 20 grams of reducing component urea, 0.1 gram of corrosion inhibitor sodium vanadate and 0.1 gram of antioxidant 4-tert-butylcatechol, Add water to 500 grams, stir evenly, adjust the acidity of the solution with 0.1 mol / liter sulfuric acid solution, and quantify it to 1000 grams with distilled water, control the pH value of the above solution to 6.5, and obtain the flue gas desulfurization and denitrification agent 1 of the present invention. The ionization constant pKa of the absorbing component is 7.

[0019] The composition (volume) of the simulated flue gas is: CO 2 : 14.4%; O 2 : 9.5%; H 2 O: 10.4%; SO 2 : 1.2%; CO: 1.1%; NO: 0.2%, H 2 S: 110mg / Nm 3 , and the rest is nitrogen.

[0020] First heat 1000 grams of desulfurization and denitrification agent 1 to 50°C, then pump the desulfurization and denitrification agent 1 from the upper end of the packed absorption to...

Embodiment 2

[0023] 10 grams of the absorption component dropropizine, 0.1 grams of the activation component diazabicyclo, 5 grams of the reducing component urea, 0.005 grams of the antioxidant N, N-bis(2-hydroxyethyl) glycine and 1 gram of the Potassium metaaluminate etchant, add water to 500 grams, stir evenly, adjust the acidity of the solution with 0.1 mol / liter phosphoric acid solution, and quantify it to 1000 grams with distilled water, control the pH value of the above solution to 7.0, and obtain the cigarette smoke of the present invention Gas desulfurization and denitrification agent 2. The ionization constant pKa of the absorbing component is 6.

[0024] The composition (volume) of the simulated flue gas is: CO 2 : 14.4%; O 2 : 9.5%; H 2 O: 10.4%; SO 2 : 1.2%; CO: 1.1%; NO: 0.2%, H 2 S: 110mg / Nm 3 , and the rest is nitrogen.

[0025] First heat 1000 grams of desulfurization and denitrification agent 2 to 30°C, then pump the desulfurization and denitrification agent 2 from ...

Embodiment 3

[0028] 80 grams of absorption component N-hydroxyethylpiperazine, 10 grams of activation component diazabicyclo, 100 grams of reduction component urea, 0.005 grams of antioxidant diphenylamine, 0.005 grams of antioxidant p-phenylenediamine and 0.025 grams Corrosion inhibitor sodium dihydrogen phosphate, add water to 500 grams, stir evenly, adjust the acidity of the solution with 0.1 mol / liter boric acid solution, and quantify it to 1000 grams with distilled water, control the pH value of the above solution to 5.5, and obtain the present invention Flue gas desulfurization and denitrification agent 3. The ionization constant pKa of the absorbing component is 5.

[0029] The composition of the simulated flue gas is (volume): CO 2 : 15.2%; O 2 : 10.3%; H 2 O: 7.6%; SO 2 : 6.1%, NO: 0.5%, and the rest is nitrogen.

[0030] After heating 1000 grams of desulfurization and denitrification agent 3 to 40°C, pump the desulfurization and denitrification agent 3 into the supergravity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com