A kind of low-temperature sulfur and nitrate removal device and treatment method of ship tail gas

A ship tail gas removal technology, applied in gas treatment, separation methods, fertilization devices, etc., can solve the problems of incomplete treatment of harmful substances, achieve high activity, reduce environmental pollution, and high desulfurization and denitrification rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

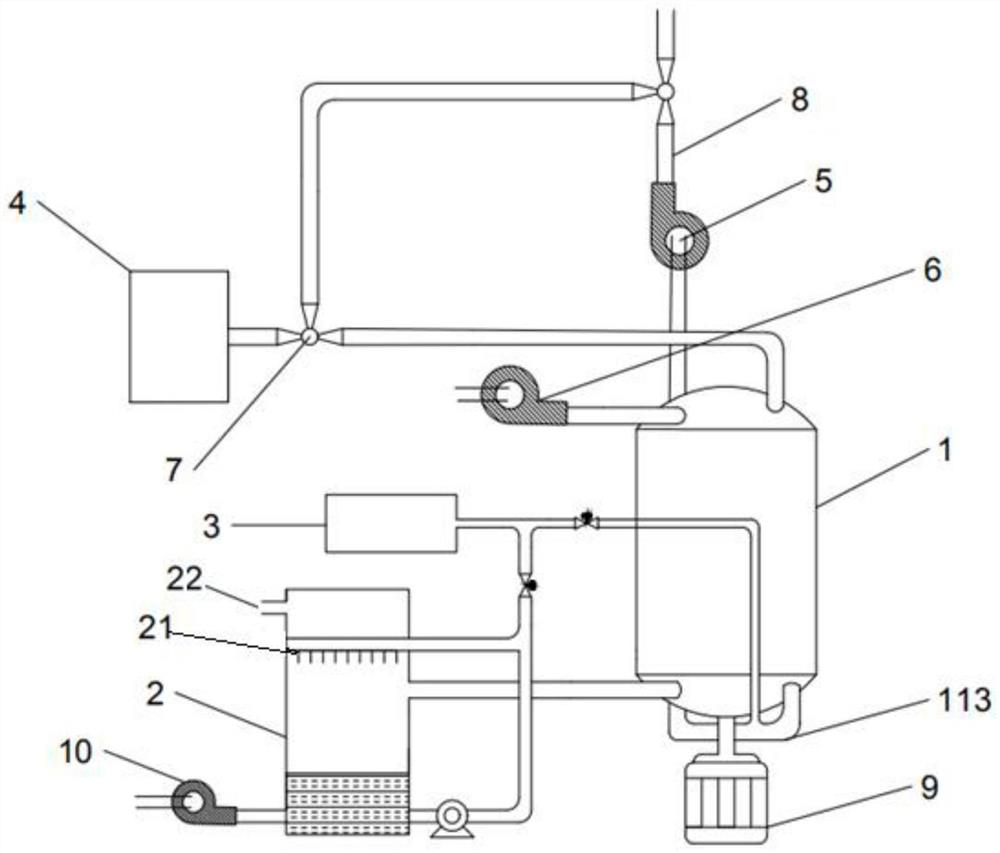

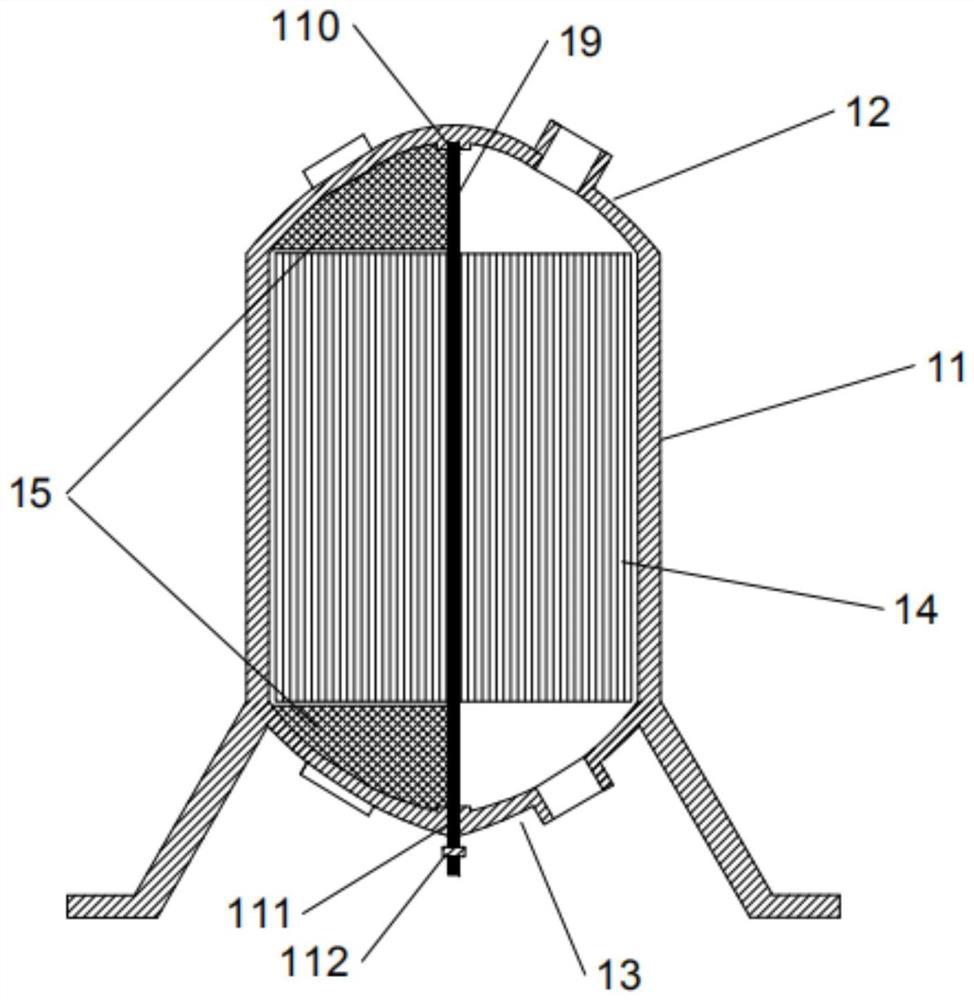

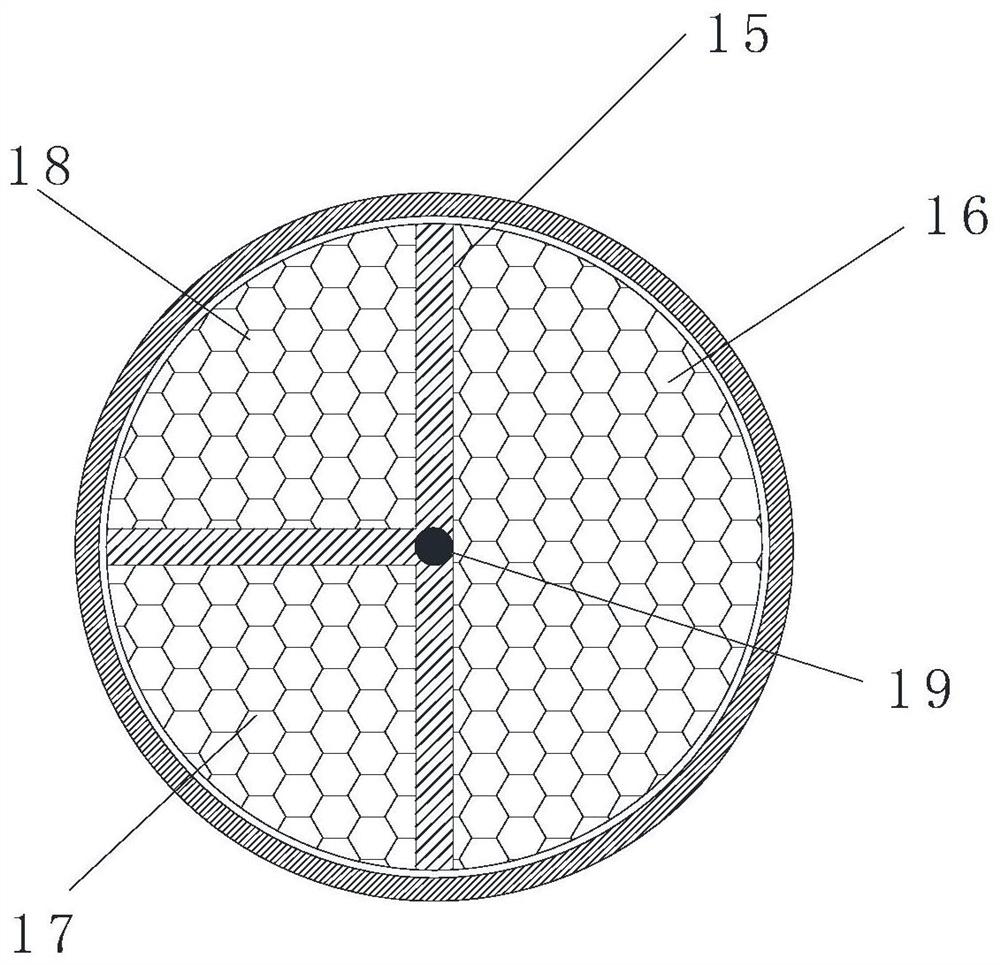

[0029] like Figure 1 to Figure 4 As shown, a low-temperature sulfur and nitric acid removal device for ship tail gas of the present invention comprises a rotary reactor 1, an ammonia water spray tower 2 and an ammonia water storage tank 3, wherein the rotary reactor 1 is provided with a cylindrical shell 11, a top The cover 12 and the bottom cover 13, the housing 11 is provided with a honeycomb column 14, the honeycomb column 14 forms a closed space with the top cover 12 and the bottom cover 13, and the rotary reactor 1 is provided with two partitions 15, The separator 15 divides the sealed space between the honeycomb column 14 and the top cover 12 and the bottom cover 13 into a first space 16, a second space 17 and a third space 18, wherein the first space 16 functions to adsorb SO 2 , the role of the second space 17 is to regenerate the adsorption materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com