Method for purifying and enriching low-concentration vanadium-containing water solution

A low-concentration, aqueous solution technology, applied in the direction of improving process efficiency, can solve the problems affecting the quality of vanadium precipitation operation products, the mud can not be processed on time, affecting the continuity of production, etc. Effect of settling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

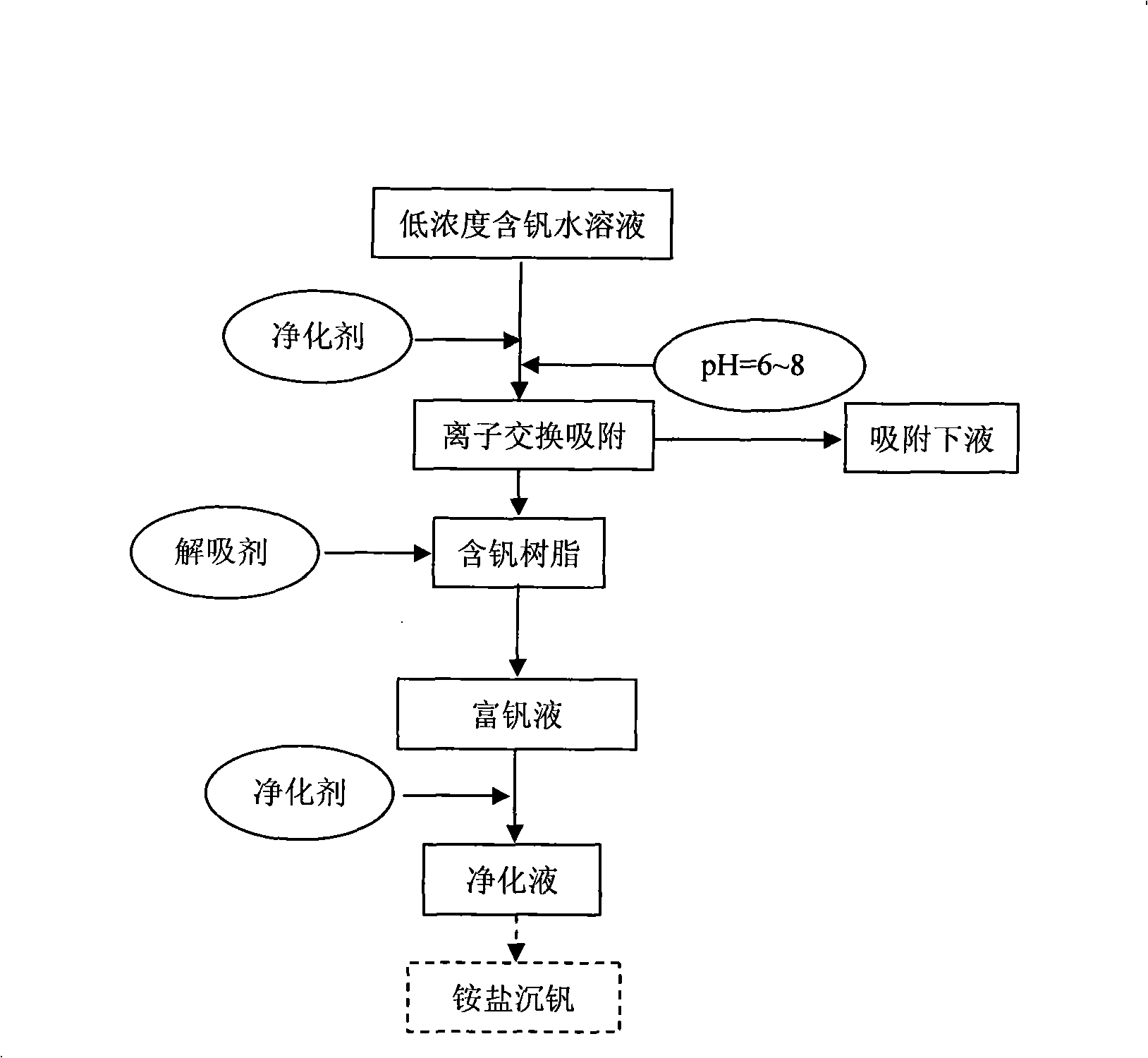

[0014] A method for purifying and enriching low-concentration vanadium-containing aqueous solution, the method for purifying and enriching such as figure 1 shown: first at V 2 o 5 Add 0.6-5.8g / L CaCl to the low concentration vanadium-containing aqueous solution with a concentration of 2000-3500mg / L 2 , adjust to pH = 6-8 after mixing; then the low-concentration vanadium-containing aqueous solution is -1 ·mL -1 The speed of the wet resin is ion-exchange adsorption through the strong basic anion exchange resin of model 201×7 until the strong basic anion exchange resin of model 201×7 is adsorbed and saturated to obtain vanadium-containing resin and adsorption liquid; then prepare 3~ The mixed solution of 4wt%NaOH+8~11wt%NaCl is used as the desorbent, the consumption of the desorbent is 3~4 times of the volume of the vanadium-containing resin, and the desorbent is 0.8~1.1mL·h -1 ·mL -1 The speed of the wet resin is desorbed by the vanadium-containing resin to obtain a vanadiu...

Embodiment 2

[0016] A method for purifying and enriching low-concentration vanadium-containing aqueous solution, the method for purifying and enriching such as figure 1 shown: first at V 2 o 5 Add 5.8-10g / L Ca(NO 3 ) 2 , adjust to pH = 6-8 after mixing; then the low-concentration vanadium-containing aqueous solution is -1 ·mL -1 The speed of the wet resin is ion-exchange adsorption through the strong basic anion exchange resin of model 201×4 until the strong basic anion exchange resin of model 201×4 is adsorbed and saturated to obtain vanadium-containing resin and adsorption liquid; then prepare 4~ A mixed solution of 5wt% NaOH+11-13wt% NaCl is used as a desorbent, the amount of the desorbent is 4-5 times the volume of the vanadium-containing resin, and the amount of the desorbent is 1.3-1.4mL h -1 ·mL -1 The speed of the wet resin is desorbed by the vanadium-containing resin to obtain a vanadium-rich solution; finally, 1.2-2.5g / L Ca(NO 3 ) 2 , solid-liquid separation to obtain pur...

Embodiment 3

[0018] A method for purifying and enriching low-concentration vanadium-containing aqueous solution, the method for purifying and enriching such as figure 1 shown: first at V 2 o 5 Add 0.6-4.6g / L MgCl to the low-concentration vanadium-containing aqueous solution with a concentration of 2000-3000mg / L 2 , adjust to pH = 6-8 after mixing; then the low-concentration vanadium-containing aqueous solution is -1 ·mL -1 The speed of the wet resin is carried out ion exchange adsorption by the strongly basic anion exchange resin of model D202, until the strong basic anion exchange resin of model D202 is adsorbed and saturated to obtain vanadium-containing resin and adsorption liquid; then prepare 3~4wt%NaOH+ A mixed solution of 8-11wt% NaCl is used as a desorbent, the amount of the desorbent is 3-4 times the volume of the vanadium-containing resin, and the amount of the desorbent is 1.1-1.3mL·h -1 ·mL -1 The speed of the wet resin is desorbed by the vanadium-containing resin to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com