Renewable flue gas desulfurization agent and preparation method thereof

A desulfurizing agent and flue gas technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of difficult by-product desulfurization gypsum, obstacles to the utilization of desulfurization gypsum, large one-time investment, etc., and achieve absorption and desorption. Appropriate process temperature difference, easy industrial production, and low desorption temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of the renewable flue gas desulfurizer comprises the following steps:

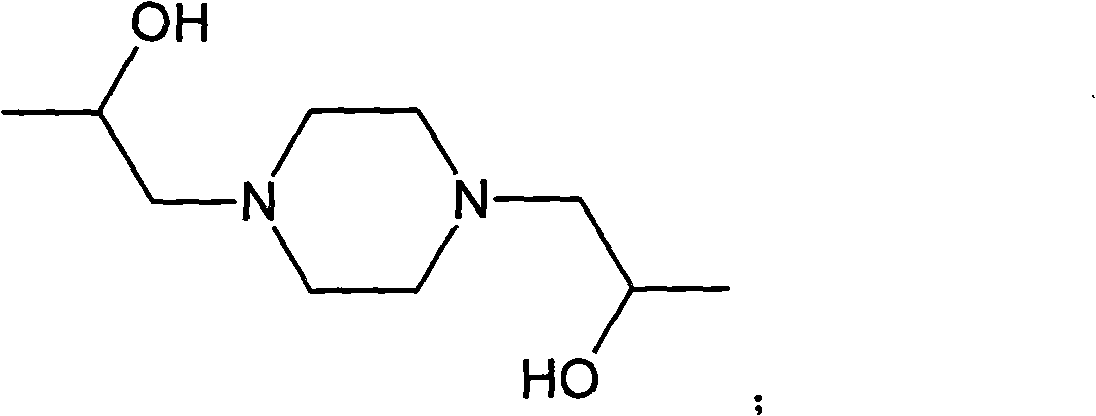

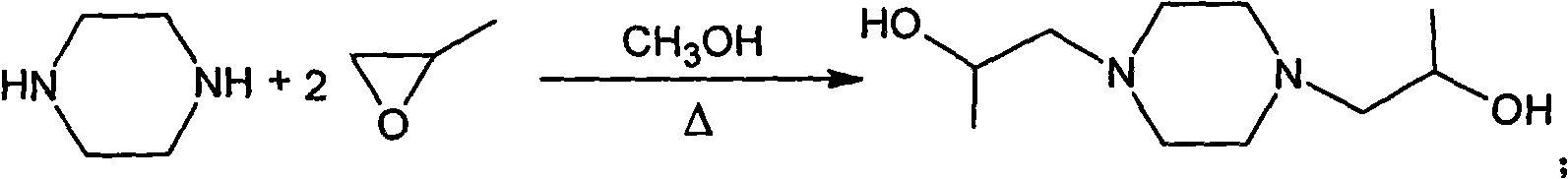

[0027] A, the preparation of 1,4-two (2-hydroxypropyl) piperazine:

[0028] Add 34.4g of anhydrous piperazine into methanol at an equal mass temperature of 60°C. After completely dissolving, slowly add 46.5g of propylene oxide dropwise under condensing and reflux stirring, and the dropping time is ≥0.5h. After the dropwise addition, keep the temperature at 65-75°C to continue the reaction for 1.0h, then cool naturally to room temperature, a large amount of white needle-like crystals are precipitated, filter the filter cake, wash with 5.0ml of methanol three times, and dry in vacuum at 60°C for 3.0h, namely 1,4-Bis(2-hydroxypropyl)piperazine is obtained. Determination of the pKa of 1,4-bis(2-hydroxypropyl)piperazine conjugate acid at 25°C by potentiometric analysis 1 3.8, pKa 2 is 8.2.

[0029]

[0030] Anhydrous piperazine Propylene oxide 1,4-bis(2-hydroxypropyl)piperaz...

Embodiment 2

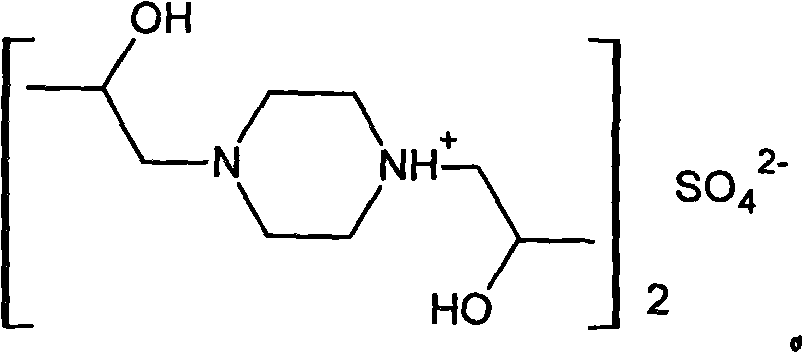

[0042] The reproducible 1,4-two (2-hydroxypropyl) piperazine mass fraction is 20% 1, the preparation method of the aqueous solution of 4-bis (2-hydroxypropyl) piperazine sulfate comprises the following steps:

[0043] A, the preparation of 1,4-two (2-hydroxypropyl) piperazine: with embodiment 1;

[0044] B, the preparation of 1,4-two (2-hydroxypropyl) piperazine sulfate aqueous solution:

[0045] Under stirring conditions, slowly add 2.2g of concentrated sulfuric acid dropwise to a beaker containing 33.8g of water, then slowly add 9.0g of 1,4-bis(2-hydroxypropyl)piperazine, and the solution obtained after completely dissolving is It is an aqueous solution of 1,4-bis(2-hydroxypropyl)piperazine sulfate with a mass fraction of 20% of 1,4-bis(2-hydroxypropyl)piperazine. Chemical reaction equation is with embodiment 1.

Embodiment 3

[0047] The reproducible 1,4-two (2-hydroxypropyl) piperazine mass fraction is 50% 1, the preparation method of the aqueous solution of 4-bis (2-hydroxypropyl) piperazine sulfate comprises the following operating steps:

[0048] A, the preparation of 1,4-two (2-hydroxypropyl) piperazine: with embodiment 1;

[0049] B, the preparation of 1,4-two (2-hydroxypropyl) piperazine sulfate aqueous solution:

[0050] Under stirring conditions, slowly add 5.5g of concentrated sulfuric acid dropwise to a beaker containing 17.0g of water, then slowly add 22.5g of 1,4-di(2-hydroxypropyl)piperazine, and the solution obtained after completely dissolving is It is an aqueous solution of 1,4-bis(2-hydroxypropyl)piperazine sulfate with a mass fraction of 1,4-bis(2-hydroxypropyl)piperazine of 50%. Chemical reaction equation is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com