Renewable flue gas desulfuration agent and applications thereof

A technology for regenerating flue gas and desulfurizing agent, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., and can solve problems such as loss of absorption of absorbents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

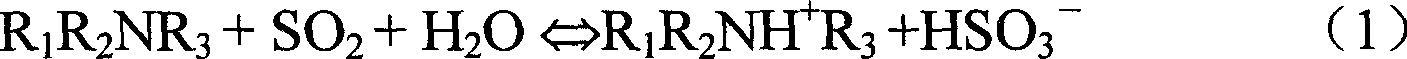

Method used

Image

Examples

Embodiment 1

[0030] Composition (weight percent) of renewable flue gas desulfurizer:

[0031] β-Hydroxyethylethylenediamine: 20%

[0032] Phosphoric acid: 10%

[0033] Citric acid: 2%

[0034] Hydroquinone: 0.2%

[0036] Deionized water: 67%

[0037] The experimental setup consists of four parts:

[0038] 1) Gas distribution system: The simulated flue gas is controlled by mass flowmeters of nitrogen, air, carbon dioxide, sulfur dioxide and nitric oxide to provide accurate gas flow to the system and form gases with different concentrations. The simulated flue gas is uniformly passed through the mixer and then enters the heating furnace to be heated and mixed with water vapor from another way to 200-300°C and enters the washing system.

[0039] 2) Washing system: The circulating washing water is extracted from the bottom of the washing tower, and after being measured by the flow meter, it enters the nozzle of the washing tower in two wa...

Embodiment 2

[0047] Composition (weight percent) of renewable flue gas desulfurizer:

[0048] 1,4-bis(2-hydroxyethyl)piperazine: 30%

[0049] Sulfurous acid: 18%

[0050] p-Phenylenediamine: 0.5%

[0052] Deionized water: 51%

[0053] The experimental device is the same as in Example 1, and the experimental conditions are: absorption temperature 55°C, liquid-gas ratio 0.5kg / m 3 .

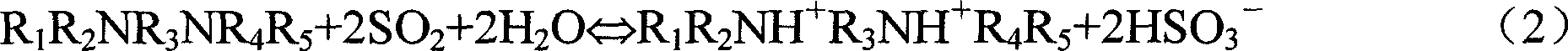

[0054] The experimental results are shown in Table 2.

[0055] Table 2 Absorption effect of desulfurizer in Example 2

[0056]

[0057] Shown by the data in table 2: the renewable flue gas desulfurizer of the present invention has an effect on SO in flue gas 2 The content fluctuates between 2000~8200mg / m 3 When fluctuating, it can ensure that the desulfurization rate is above 90%, the regeneration steam consumption is low, and the steam consumption is reduced by more than 30%.

Embodiment 3

[0059] Composition (weight percent) of renewable flue gas desulfurizer:

[0060] 1,4-bis(2-hydroxypropyl)piperazine: 10%

[0061] Hydroxyethylpiperazine: 15%

[0062] Sulfuric acid: 8%

[0063] Sulfurous acid: 7%

[0064] p-Phenylenediamine: 0.5%

[0066] Deionized water: 58.5%

[0067] The experimental device is the same as that in Example 1, and the experimental conditions: the absorption temperature is 40°C, and the liquid-gas ratio is 1kg / m 3 .

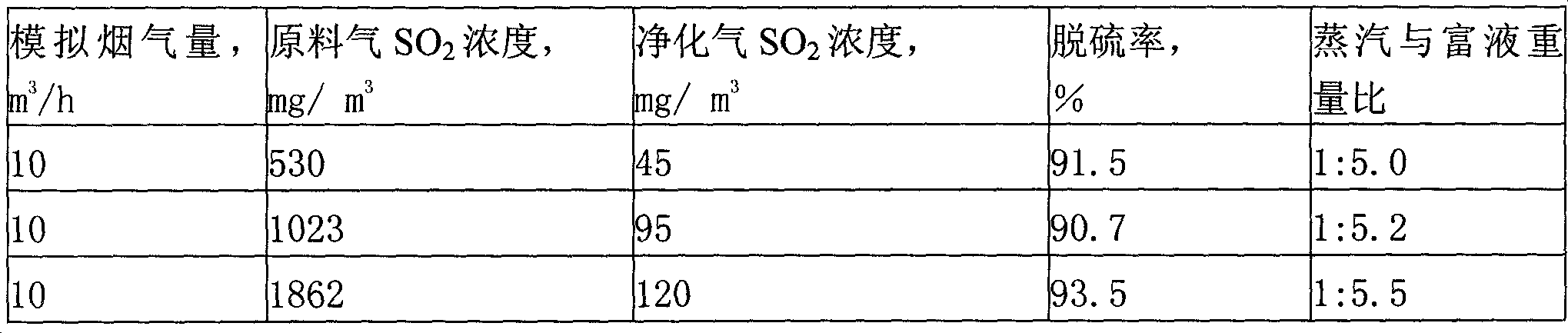

[0068] The experimental results are shown in Table 3.

[0069] Table 3 Example 3 Desulfurization agent absorption effect

[0070]

[0071] Shown by the data in table 3: the renewable flue gas desulfurizer of the present invention has an effect on SO in flue gas 2 The content is 1500~2500mg / m 3 When fluctuating, the desulfurization rate can be guaranteed to be around 96%, and as the absorption temperature decre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com