Method for recovering high yield and high purity hydrogen and ethylene from refinery dry gas

A refinery dry gas, high-yield technology, applied in chemical instruments and methods, hydrogen separation, hydrocarbons, etc., can solve the problems of high energy consumption, absorbent and equipment investment, and inability to recover hydrogen at the same time, to achieve cold oil The effect of increasing the dew point at the top of the absorption tower, reducing operating costs, and reducing the amount of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

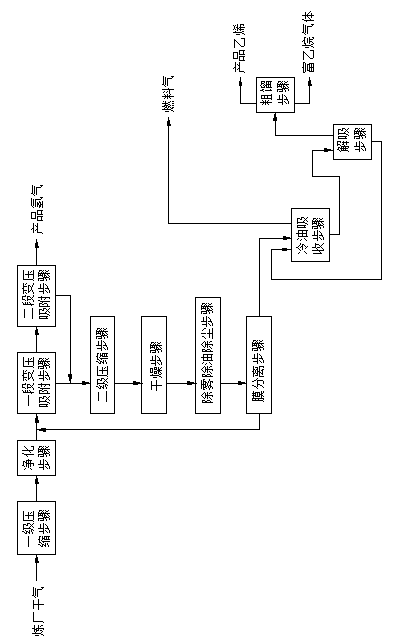

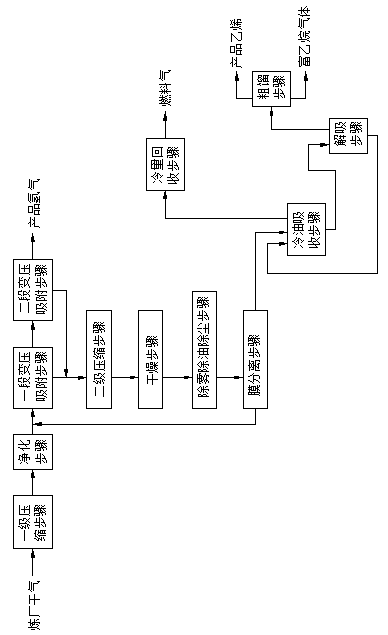

[0038] Such as figure 1 As shown, the method for recovering hydrogen and ethylene with high yield and high purity from refinery dry gas is characterized in that it comprises the following steps:

[0039] One-stage compression step: dry the refinery with a hydrogen content of 56.2%, an ethane content of 7.2%, an ethylene content of 6.2%, a methane content of 22.2%, a nitrogen content of 5.5%, a carbon dioxide content of 0.9%, and an acid gas content of 1.8%. The pressure of gas (volume ratio) is raised to 0.7Mpa.

[0040] Purification step: use the existing low-temperature methanol washing process to remove carbon dioxide, sulfur dioxide, hydrogen sulfide and other acid gases in the refinery dry gas with a pressure of 0.7 MPa obtained in the first-stage compression step.

[0041] The first-stage PSA regeneration step: send the dry gas from the refinery to the first-stage PSA regeneration tower for pressure swing adsorption at 30°C. It is clear to those skilled in the art that...

Embodiment 2

[0053] Such as figure 1 As shown, the method for recovering hydrogen and ethylene with high yield and high purity from refinery dry gas is characterized in that it comprises the following steps:

[0054] One-stage compression step: dry the refinery with 46.5% hydrogen content, 12.4% ethane content, 6.0% ethylene content, 20% methane content, 9.5% nitrogen content, 2.2% carbon dioxide and above components, and 3.2% acid gas content. The pressure of gas (volume ratio) is raised to 1.0Mpa.

[0055] Purification step: use the existing low-temperature methanol washing process to remove carbon dioxide, sulfur dioxide, hydrogen sulfide and other acid gases in the refinery dry gas with a pressure of 1.0 MPa obtained in the first-stage compression step.

[0056] The first-stage PSA regeneration step: send the dry gas from the refinery to the first-stage PSA regeneration tower for pressure swing adsorption at 30°C. It is clear to those skilled in the art that pressure swing adsorption...

Embodiment 3

[0068] Such as figure 1 As shown, the method for recovering hydrogen and ethylene with high yield and high purity from refinery dry gas is characterized in that it comprises the following steps:

[0069] One-stage compression step: dry the refinery with 18.5% hydrogen content, 14.5% ethane content, 16% ethylene content, 30% methane content, 14.5% nitrogen content, 3.5% carbon 2 or higher component content, and 3% acid gas content. The pressure of gas (volume ratio) is raised to 0.7Mpa.

[0070] Purification step: use the existing low-temperature methanol washing process to remove carbon dioxide, sulfur dioxide, hydrogen sulfide and other acid gases in the refinery dry gas with a pressure of 1.2 MPa obtained in the first-stage compression step.

[0071] The first-stage PSA regeneration step: send the dry gas from the refinery to the first-stage PSA regeneration tower for pressure swing adsorption at 30°C. It is clear to those skilled in the art that pressure swing adsorption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com