A two-phase mixture for capturing carbon dioxide

A carbon dioxide and titanium oxide technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of low decarburization capacity, high regeneration energy consumption, strong equipment corrosion, etc., to improve the desorption rate, The effect of reducing energy consumption for regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

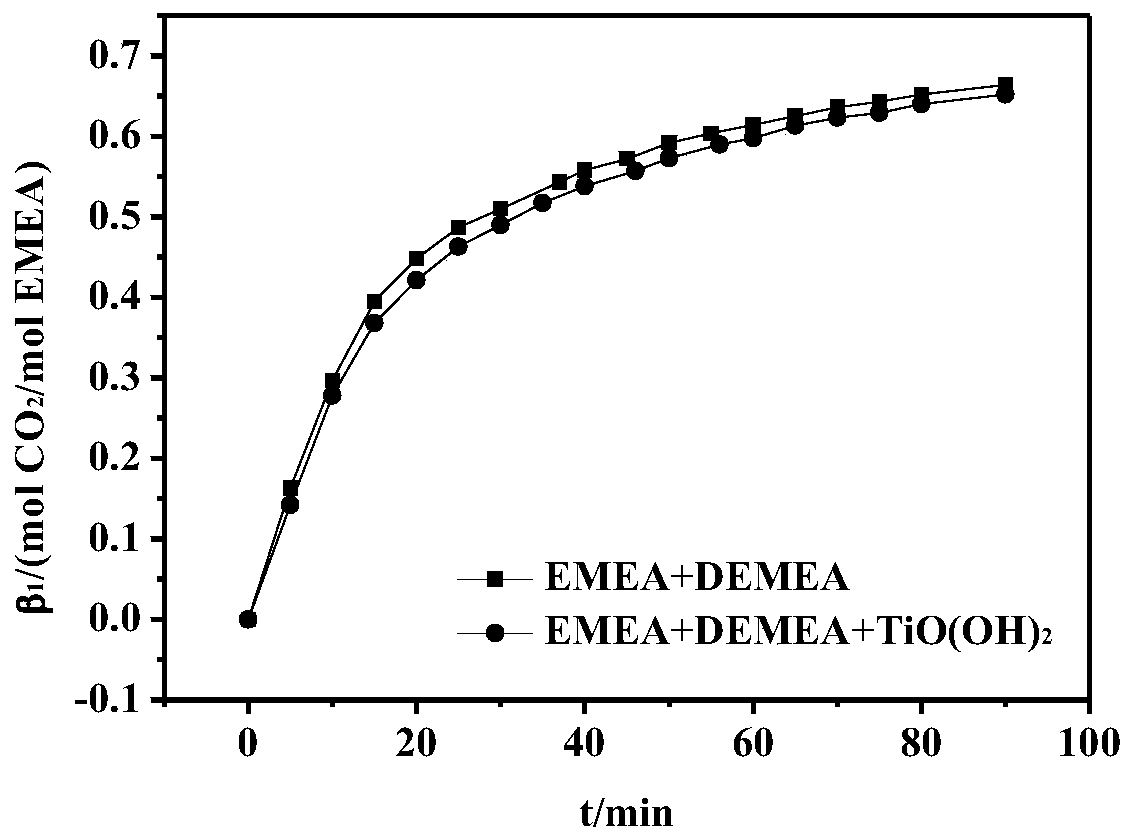

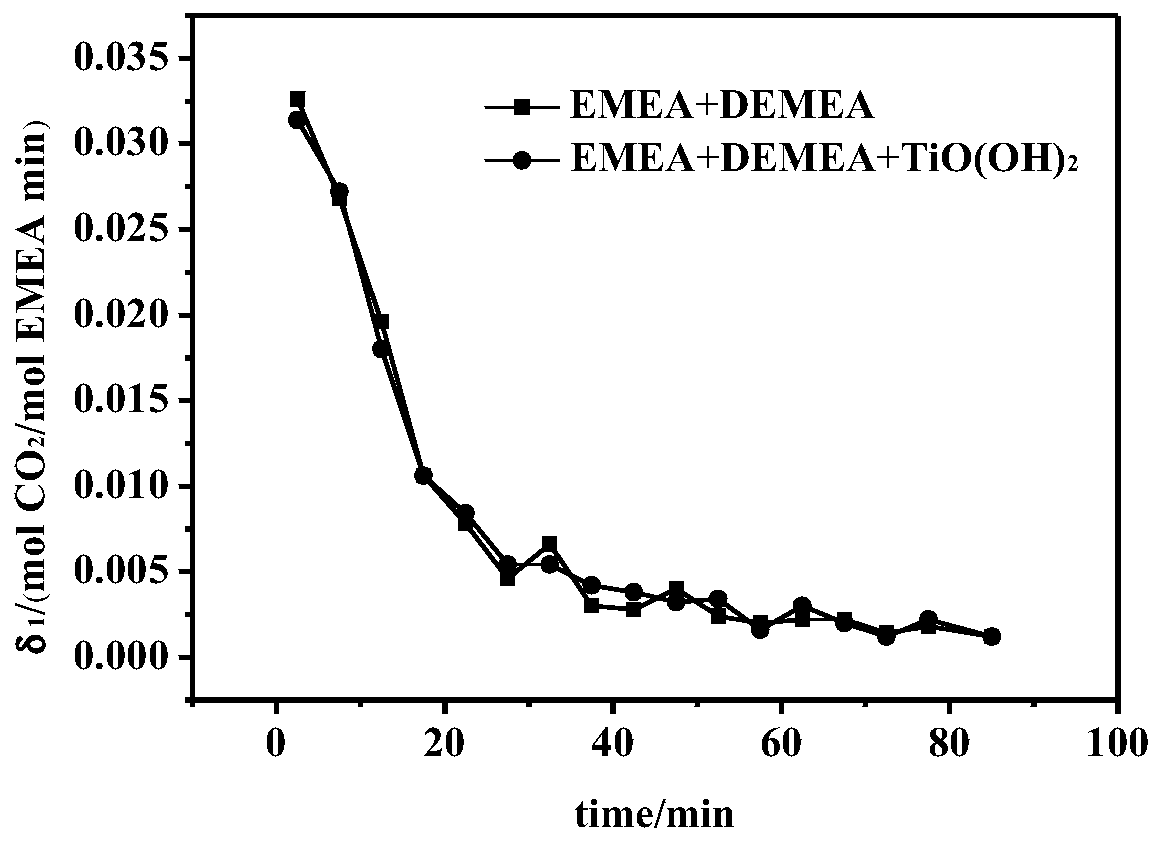

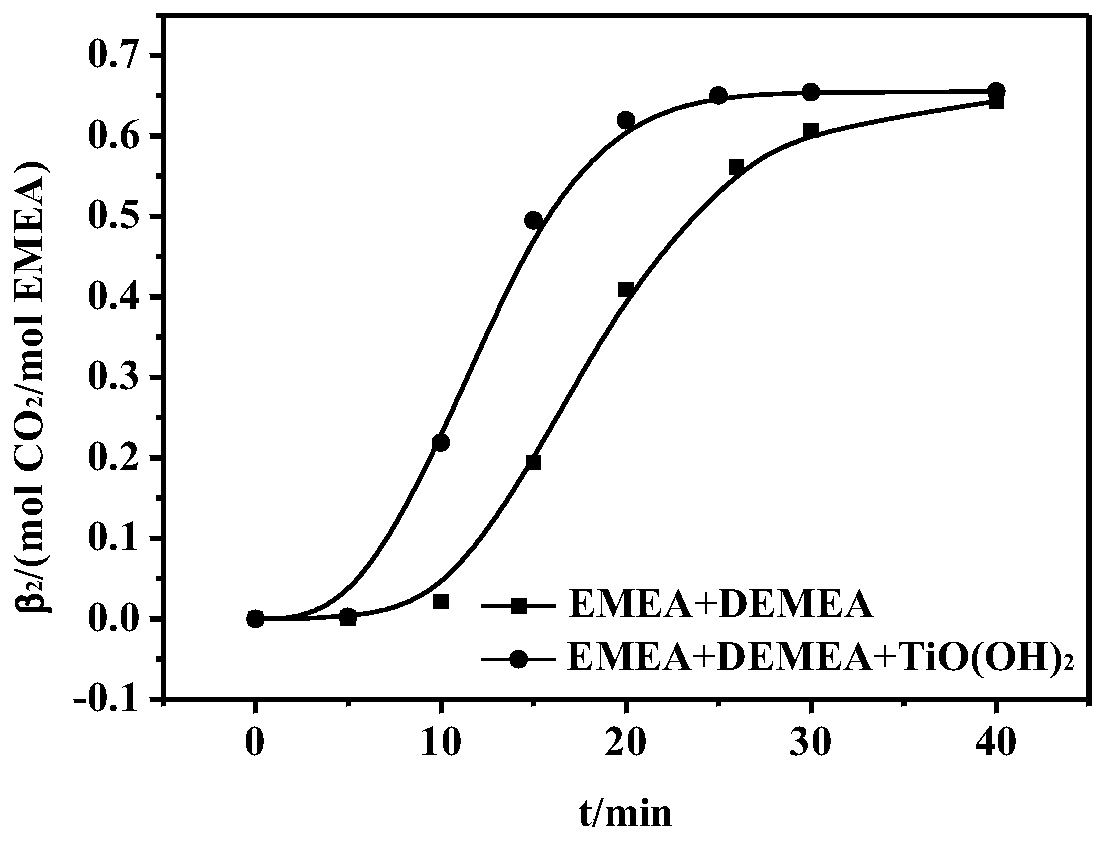

[0043] 100g 30wt%EMEA+70wt%DEMEA+1g TiO(OH) 2 The two-phase mixture of packing into 250ml is furnished with in the reactor of constant temperature oil bath stirrer (experimental apparatus sees Figure 11 ). At a temperature of 40°C, at a flow rate of 250ml / min, CO with a pressure of 0.2MPa and a concentration of 99.995% was introduced. 2 , use a wet anti-corrosion flowmeter for continuous measurement, and calculate the absorption of carbon dioxide (see figure 1 , see Table 1), absorption rate (see figure 2 ). After the solution reaches saturation, set the temperature of the oil bath to 120°C for desorption, and measure the amount of desorption (see image 3 ) and desorption rate (see Figure 4 ), after five absorption and desorption experiments, the stability of the two-phase mixture was observed (see Figure 5 ). Characterization of TiO(OH) by XRD, FT-IR and SEM 2 stability (see Figure 6 ,7,8,9). pass 13 C NMR characterization of the product of the liquid phase E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com