Reinforced gas extraction method based on phase change pulse wave

A gas extraction and pulse wave technology, which is applied in the field of enhanced gas extraction based on phase change pulse wave, can solve the problems of large fracturing affected area, large gas desorption amount and high success rate, and achieves the increase of fracturing affected area, The effect of increased gas concentration and low cost of extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

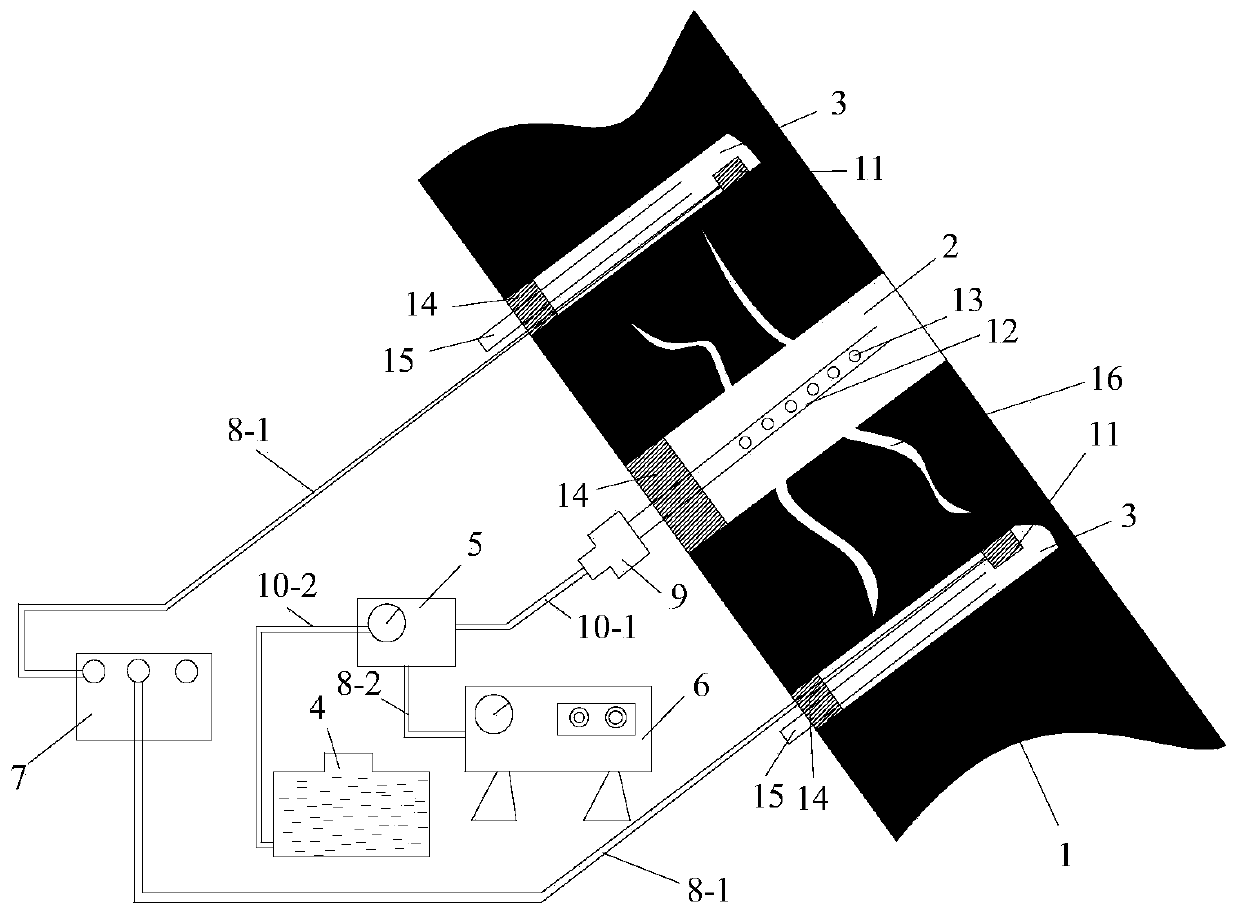

[0021] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0022] figure 1 As shown, an enhanced regional gas drainage method based on phase-change pulse waves: first, phase-change fracturing holes 2 are constructed on the side of the roadway in vertical coal seam 1, and pulse induction holes 3 are respectively constructed at 10m positions at both ends of phase-change fracturing holes 2, The phase change fracturing hole 2 has a diameter of 120-130mm and a length of 120m, and the pulse induction hole 3 has a diameter of 40-50mm and a length of 120m; In the crack hole 2, one end of the phase change fracturing tube 12 is sent to the bottom of the phase change fracturing hole 2. The phase change fracturing tube 12 has a diameter of 25 mm and a length of 124 m. There are several small holes on the wall of the phase change fracturing tube 12 13; connect the gas extraction pipes 15 in sequence, respectively sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com