Apparatus and method for gas extraction through complex strata with pipe protection holes

A technology for extracting gas and complex strata, applied in drilling equipment and methods, gas discharge, safety devices, etc. cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

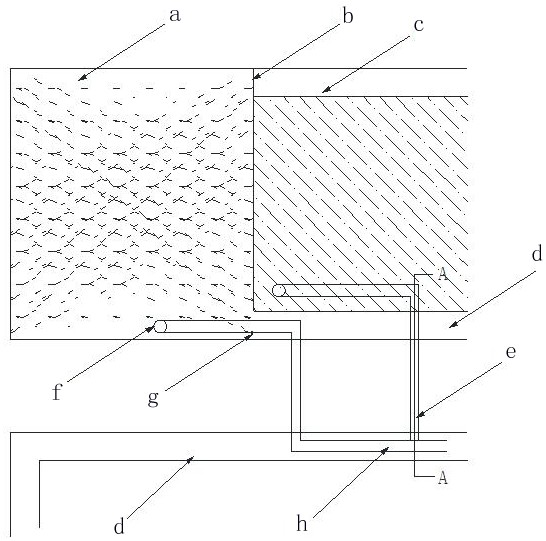

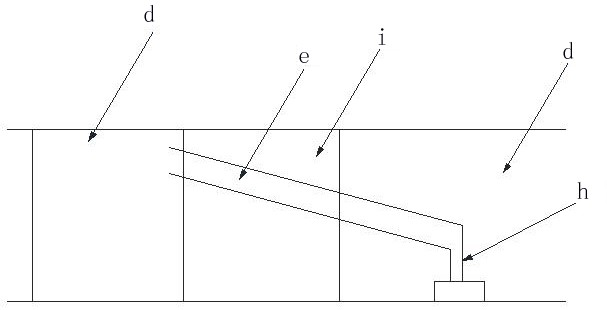

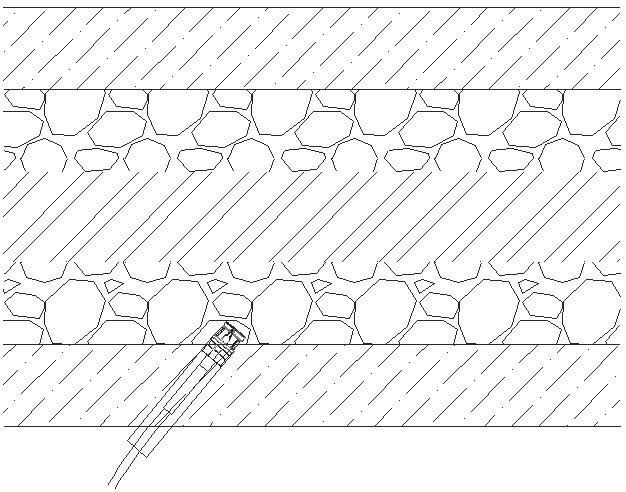

[0038]The utility model relates to a device for gas extraction through complex strata following a pipe and protecting a hole, comprising a traveling mechanism, a power input device, an angle adjustment mechanism, a center directional drilling assembly and an external hole protecting assembly, and a power input device and an angle adjustment mechanism are installed on the traveling mechanism. A central directional drilling assembly is installed on the angle adjustment mechanism, and the power input device drives the central directional drilling assembly. like Figure 5 , 6 As shown, the central directional drilling assembly includes a drill pipe 3, a pilot drill bit 30, an alloy drill bit 32, a guide head control assembly 29, a down-the-hole hammer 27 and a reducing adapter 28, and the front end of the drill pipe 3 is connected with the down-the-hole hammer 27 , the down-the-hole hammer 27 is connected with the guide head control assembly 29 through the reducing joint 28, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com