Gas extraction system and method for thick and hard roof high-gas coal seam

A coal seam gas and gas drainage technology, which is applied in the field of thick and hard roof and high gas coal seam gas drainage system, can solve the problems of damage to the integrity of thick and hard roof and the influence of advancing speed, and achieve high construction efficiency, high implementation efficiency, and high construction efficiency. The effect of simple structure composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

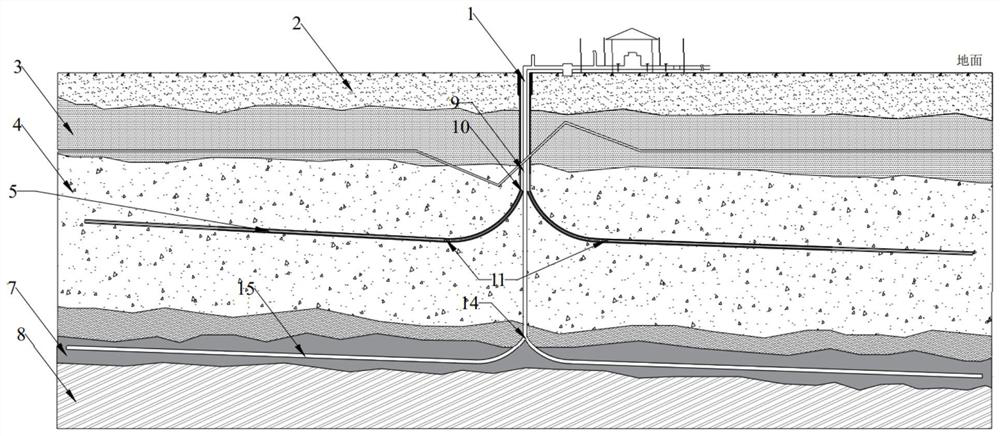

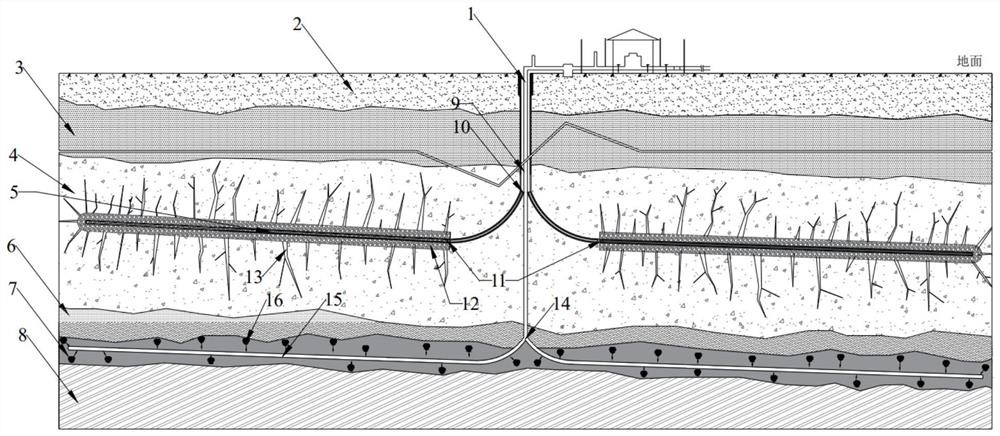

[0041] For high-gas mines, the amount of gas gushing out from coal seams is large during the mining process, and the risk of coal and gas outburst is high, which seriously threatens the safety of roadway operations in the working face. In the process, the overhanging area of the basic roof is large, and pressure from too long a distance will cause a rock burst accident, which also seriously threatens the safe and efficient production of the mine.

[0042] In the existing technology, for mines with both thick and hard basic roof and high gas, two independent treatment methods are used to deal with them separately, and the construction location and construction structure are not related to each other. For the elimination of thick and hard basic roof, the Reasonable setting of coal pillars, deep hole blasting and roof cutting for pressure relief, etc., both of which require relevant operations after mining at the working face; The roof of the upper part of the coal seam is dril...

Embodiment 2

[0048] This embodiment provides a gas drainage method for a thick, hard roof and high gassy coal seam, based on the gas drainage system for a thick and hard roof and high gassy coal seam in Example 1, the steps are as follows:

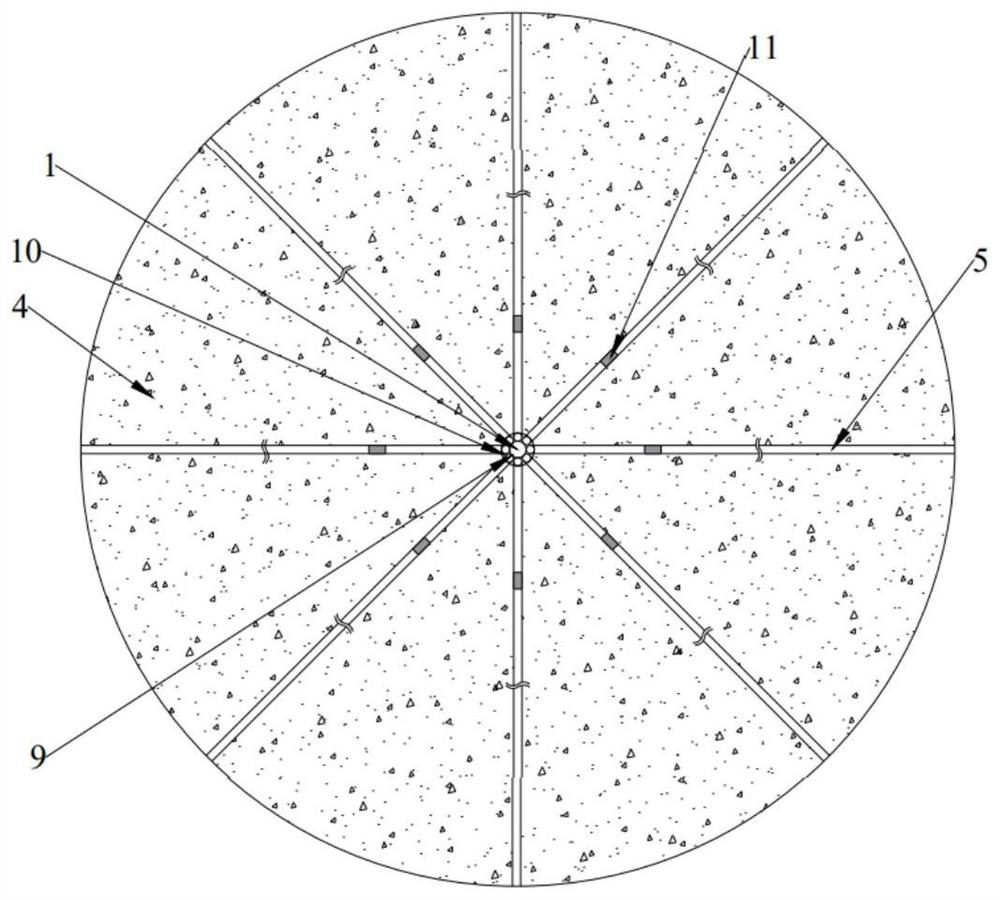

[0049] 1. Set up a large borehole. Before the mining of the working face, arrange a gas machine room on the ground, open a large borehole 1 vertically downward from the ground next to the gas machine room, and reinforce the large borehole 1 to ensure that it can It will be used for a long time until the blasting and pressure relief work of the basic roof and the gas drainage work are completed, and the large borehole 1 will be opened to the position of the hard rock formation 4 of the basic roof;

[0050] 2. Set up blasting drill holes. From the bottom 10 of the big drill hole 1, a number of blast drill holes 5 are extended along the circumference. The blast drill holes 5 are divergent and evenly opened at 4 hard rock formations on the basic top. Subseq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com