Device and method for desorption of gas in coal seam by utilizing ultrasonic principle

A coalbed methane and gas technology, which is applied in the field of gas desorption devices, can solve problems such as the influence of gas purity, complicated gas separation procedures, etc., and achieve the effects of increasing the number of coal seam cracks, expanding pores, and increasing the amount of desorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, a specific embodiment of the present invention will be described in detail with reference to the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

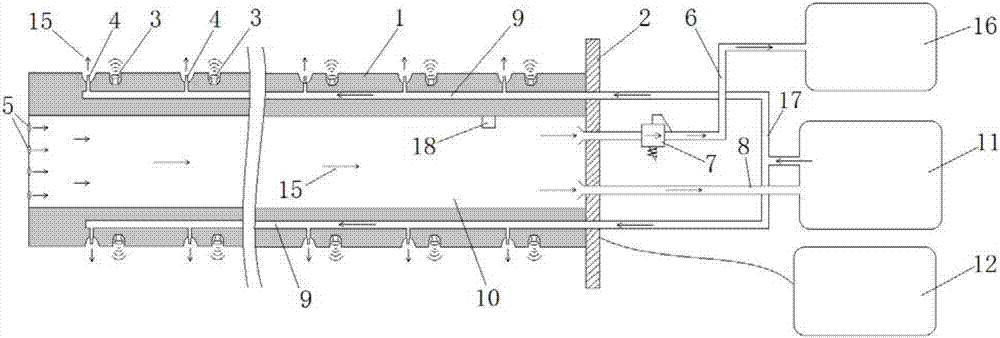

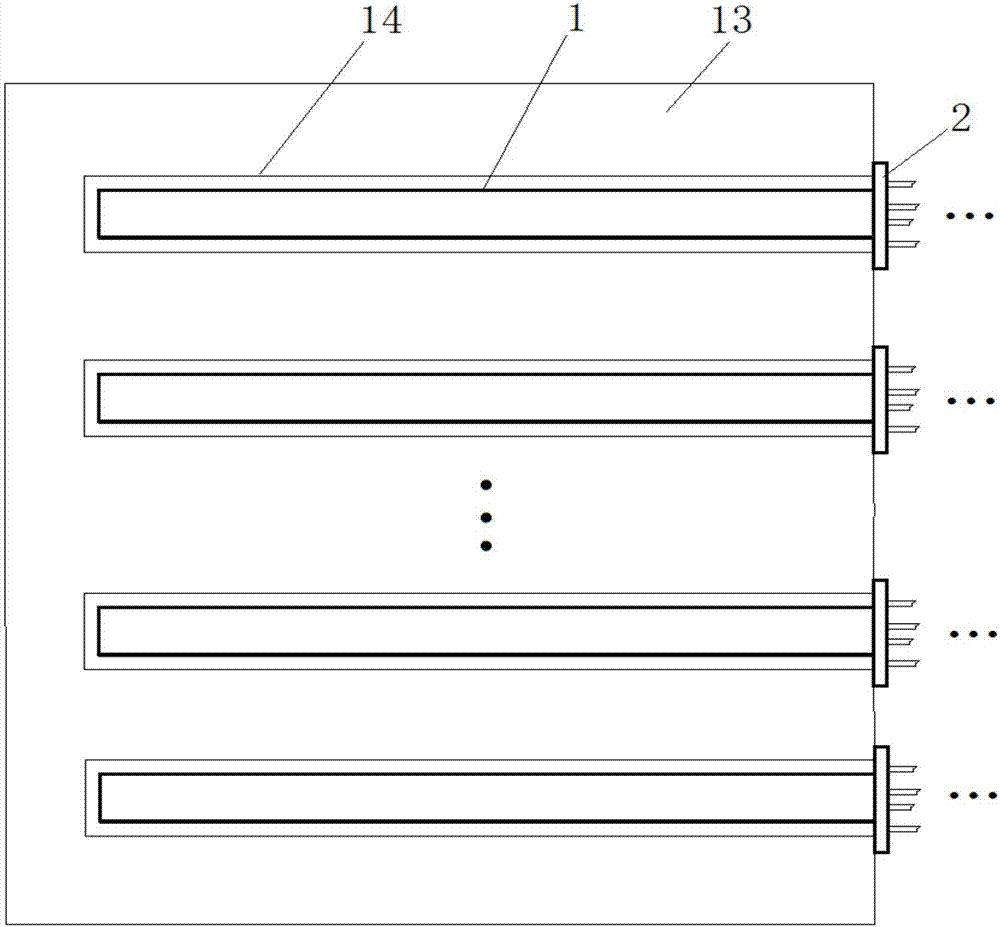

[0023] See figure 1 As shown, this embodiment provides a device and method for desorbing gas in a mining coal seam using the principle of ultrasound. The device includes a plurality of gas gas desorption columns, and each gas gas desorption column is correspondingly placed in the mining coal seam. 13 in each coalbed methane recovery well 14; the gas gas desorption column includes a column 1, a plurality of ultrasonic emitting heads 3 and a plurality of gas nozzles 4 are distributed on the side of the column 1, the column 1 A gas inlet passage 10 and a gas outlet passage 9 are provided inside. The gas inlet passage 10 is provided with a pressure sensor 18 for measuring gas pressure. The gas inlet passage 10 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com