Low-energy-consumption desorption system and method for carbon dioxide through cooperation of catalyst and external field reinforcement

A technology of carbon dioxide and catalyst, which is applied in the field of catalyst synergistic external field enhanced carbon dioxide desorption system with low energy consumption, which can solve the problems of low desorption rate, low tower height and complex working conditions, so as to increase the amount of gas desorption, complete desorption reaction and avoid high temperature The effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

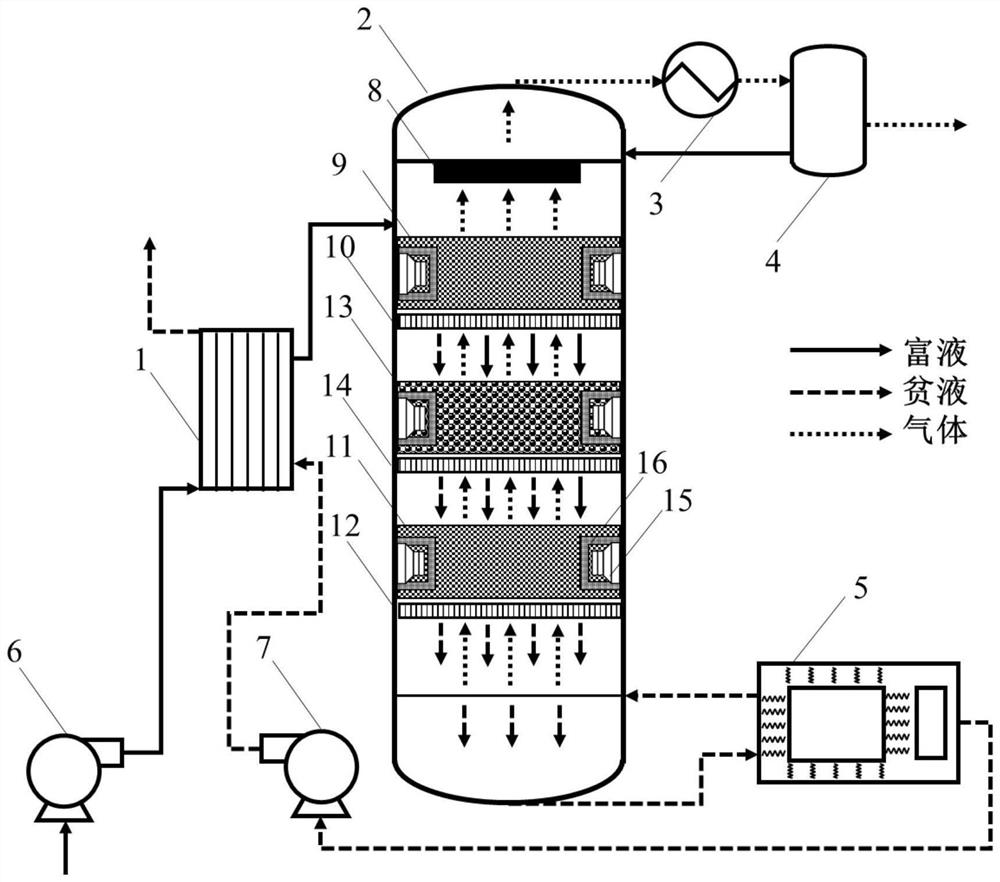

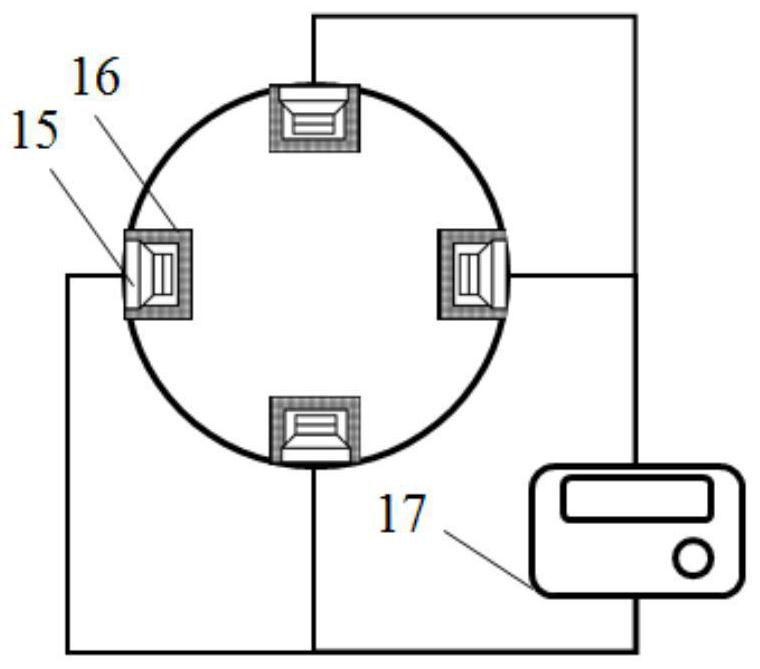

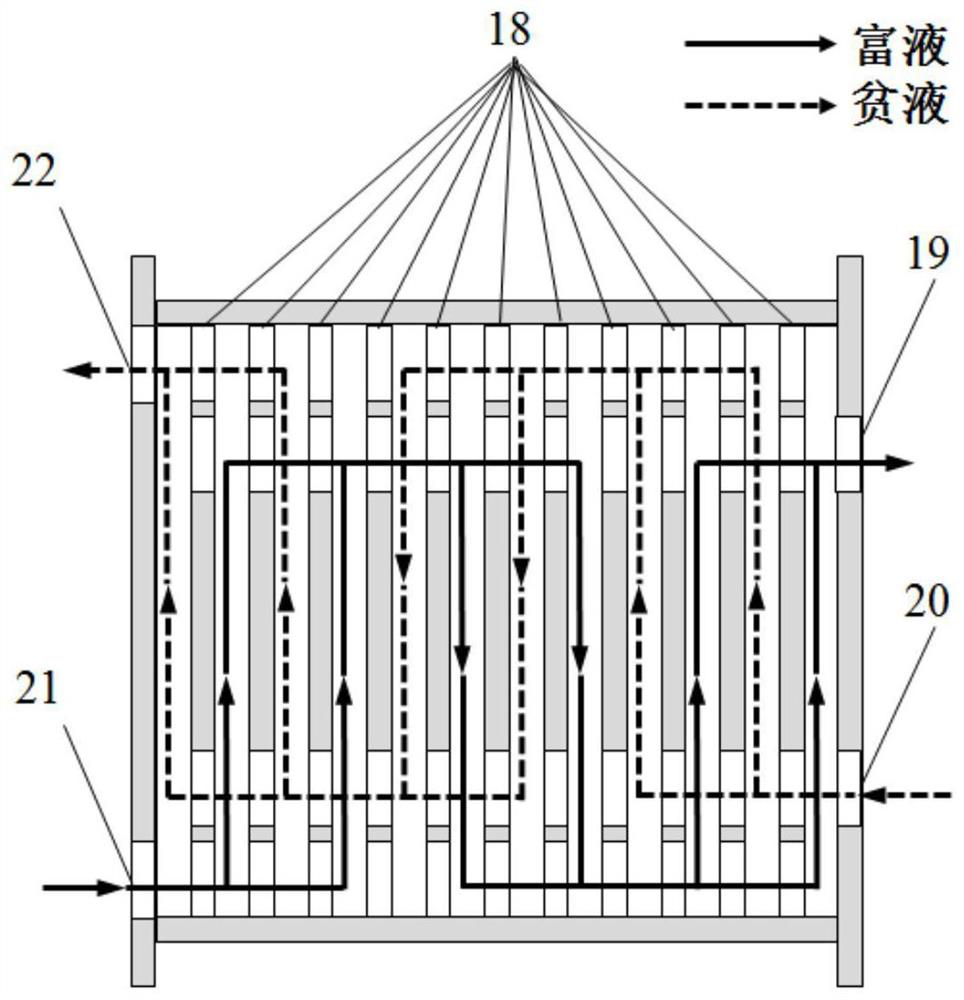

[0043] refer to Figures 1 to 4 , a catalyst cooperates with an external field to strengthen carbon dioxide low-energy consumption desorption system, the system includes a lean-rich liquid heat exchanger 1, a desorption tower 2, a gas-liquid cooler 3 and a gas-liquid separator 4 that are connected in sequence, and the gas-liquid separator 4 is communicated with the desorption tower 2, and the desorption tower 2 is also communicated with the microwave reboiler 5; the desorption tower 2 is provided with a packing area and a catalytic area, and the packing area and the catalytic area are respectively provided with ultrasonic strengthening The lean-rich liquid heat exchanger 1 is communicated with the rich-liquid delivery pump 6 and the lean-liquid delivery pump 7 respectively; the desorption tower is provided with a mist eliminator 8 at the top.

[0044] The packing area includes a first packing area and a second packing area, the first packing area includes a first metal packing...

Embodiment 2

[0049] The traditional desorption method is: absorption of CO 2 The 50-60 ℃ rich liquid and the desorbed 100-110 ℃ depleted liquid are heated by heat exchange, the heated 80-90 ℃ rich liquid enters the desorption tower, and the lean liquid is vaporized by the 110 ℃ reboiler to become the desorption tower The rich liquid inside provides desorption energy, and the lean liquid vaporized by the reboiler is reversely contacted with the rich liquid to complete the desorption. The contact area only passes through the packing area, and the heat source of the reboiler is heated by steam or electricity. The desorbed gas mixture is cooled and the liquid after gas-liquid separation continues to be injected into the desorption tower for circulation. The desorption energy consumption using the traditional desorption method is 4 GJ / t CO 2 .

[0050] The present invention adopts the system of Example 1. On the basis of the traditional desorption method, a catalyst zone where shaped catalyst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com