Double-purpose vapor and electric-heating three-shaft desorption and permeation test device

A technology of permeation experiment and electric heating, which is applied in the direction of measuring devices, permeability/surface area analysis, material inspection products, etc., can solve the problems of small gas volume, closed pressure cracks, limited application range, etc., to increase the amount of gas desorption, The effect of increasing penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

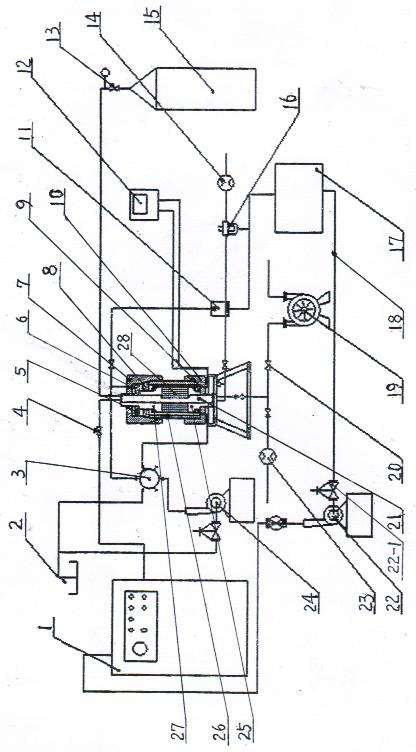

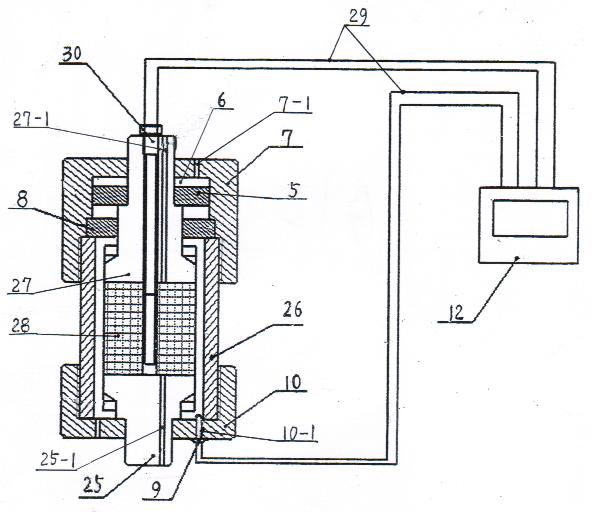

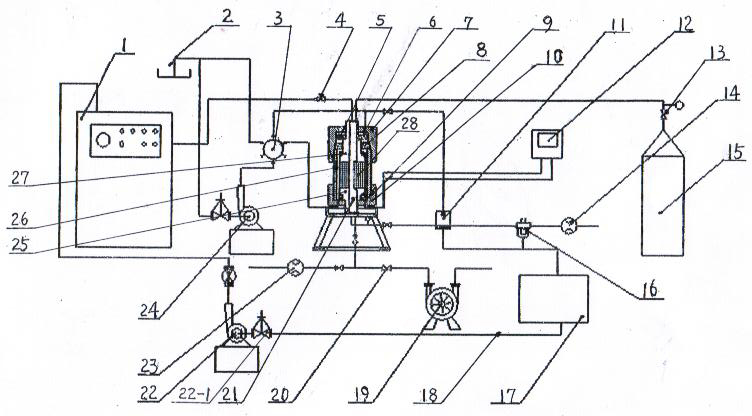

[0011] Examples, see attached figure 1 , The steam heating device and the electric heating device share a sleeve 26, upper and lower pressure caps 7, 10 and the device in the sleeve 26 of the steam and electric heating dual-purpose triaxial desorption permeation experimental device. The whole device of steam heating is that the upper end of the sleeve 26 of the triaxial pressure chamber 6 is screwed to the upper pressure cap 7, and the lower end of the sleeve 26 is screwed to the lower pressure cap 10, and a coal sample 28 is housed in the middle of the sleeve 26. Coal sample 28 tops load onto pressure head 27, the bottom of coal sample 28 dresses down pressure head 25, upper and lower pressure heads 27,25 stretch out the central hole of upper and lower pressure caps 7,10 respectively. A steam channel 21 is established at the center holes of the upper and lower pressure caps 7, 10 and the coal sample 28. The baffle plate 8 is installed at the junction of the sleeve 26 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com