A Method for Strengthening Regional Gas Drainage with Hydrothermal Coupled Fracturing

A gas extraction, hydrothermal coupling technology, applied in gas discharge, mining fluid, mining equipment, etc., can solve the problems of heavy workload, insufficient pressure relief, high cost, increase the area affected by fracturing, and increase gas desorption. The effect of promoting the development of fissures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

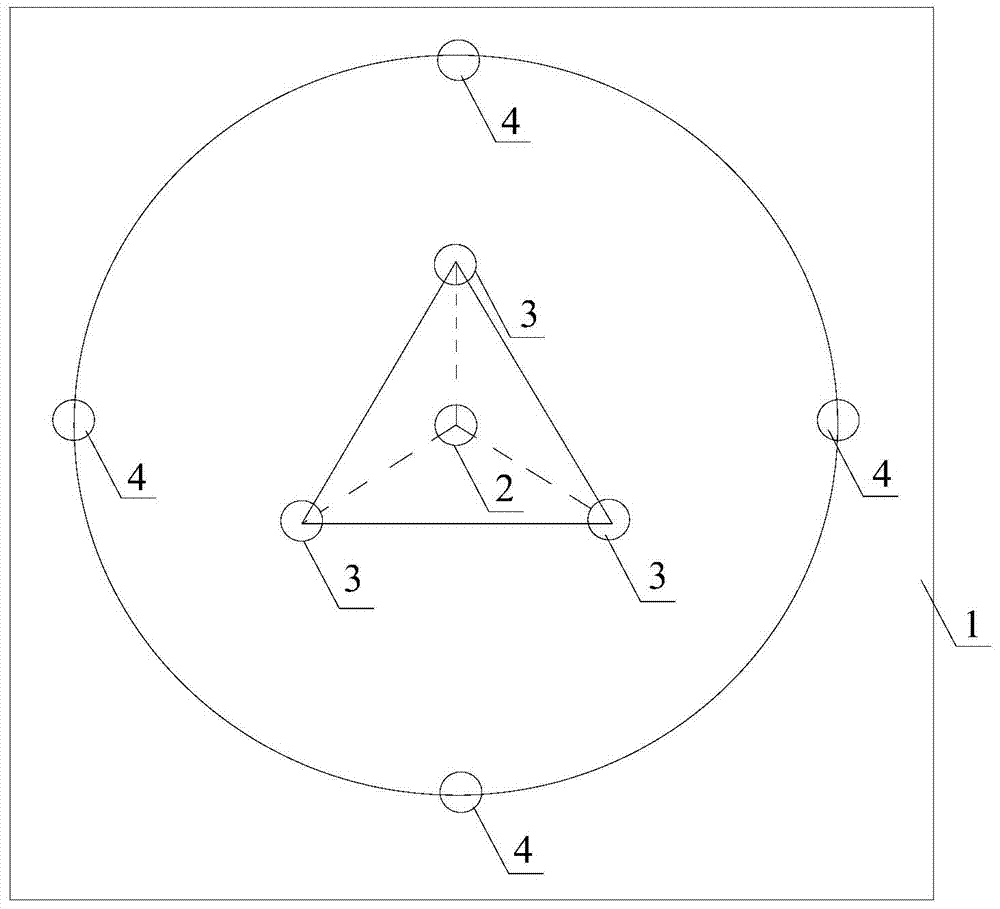

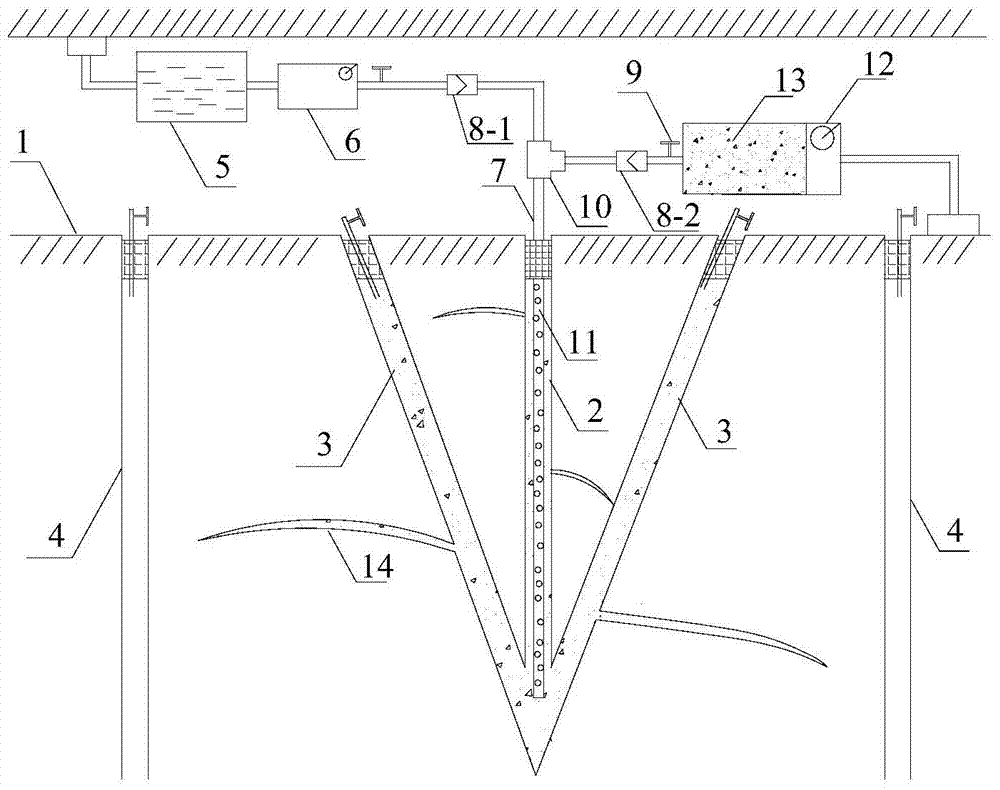

[0019] figure 1 with figure 2 As shown, a hydrothermal coupling fracturing enhanced regional gas drainage method: First, the main fracturing hole 2 and three branch fracturing holes 3 are sequentially constructed on the coal seam roadside 1, and the main fracturing holes 2 are arranged in an equal position. At the center of the side triangle, the opening positions of the three branch fracturing holes 3 are respectively arranged at the three vertices of the equilateral triangle, and the terminal holes of the three branch fracturing holes 3 meet at the center line of the equilateral triangle , forming a regular triangular pyramid with the equilateral triangle as the base and the branch fracturing hole 3 as the edge, so that the main fracturing hole 2 and the three branch fracturing holes 3 are connected in the coal seam, and the main fracturing ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com