Method for strengthening gas extraction through cooperation of hydraulic punching and cave forming and steam injection

A technology of gas drainage and hydraulic punching, which is applied in the direction of mining fluid, earthwork drilling, flushing wellbore, etc., and can solve problems such as hindering gas drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below.

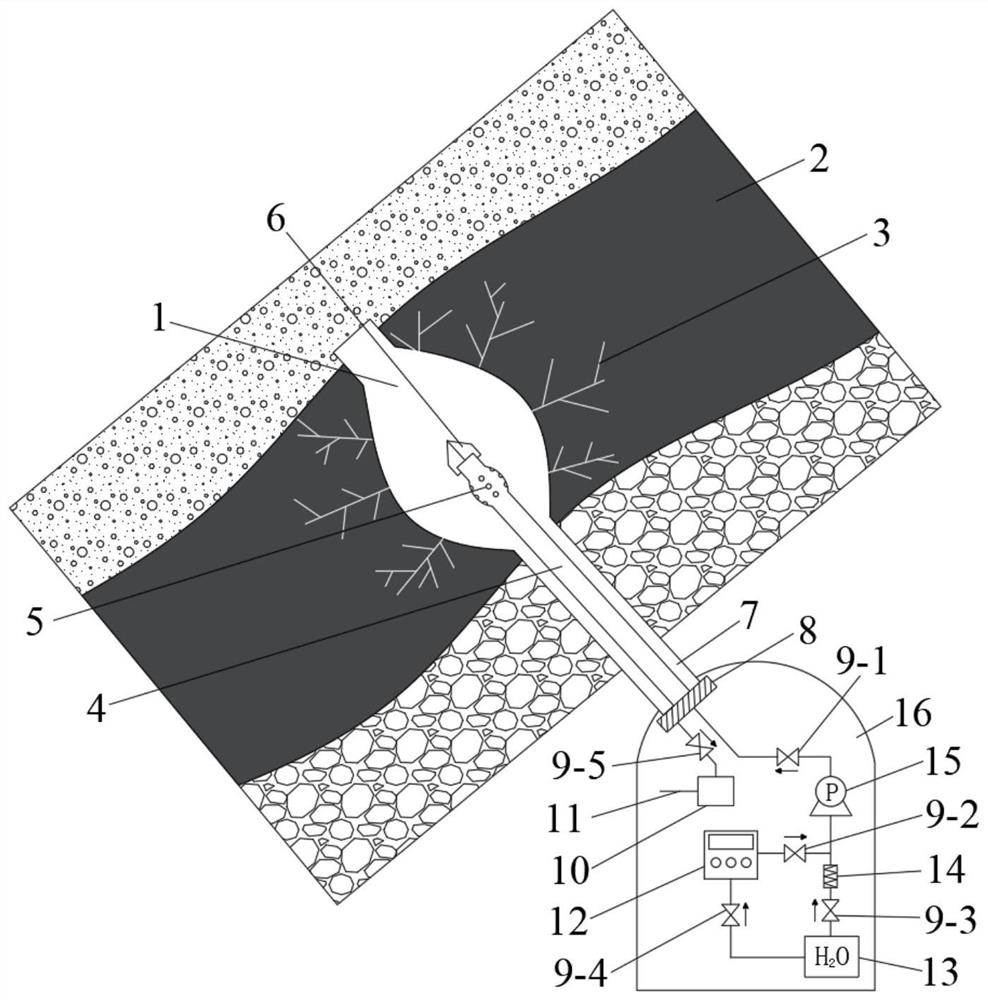

[0019] Such as figure 1 Shown, concrete steps of the present invention are:

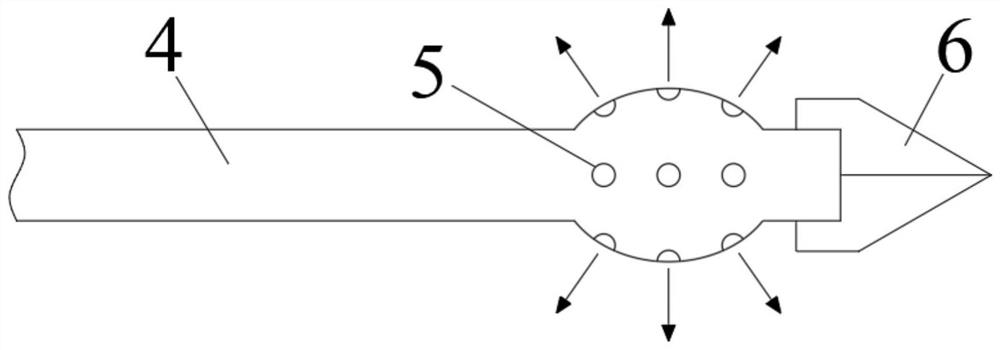

[0020] A. Construction layer-penetrating drilling: use the drilling-punching machine to construct the layer-penetrating drilling 7 from the rock roadway 16 to the upper coal seam 2, so that the hollow drill pipe 4 of the drilling-punching machine extends into the coal seam 2 until the hollow drill pipe 4 The drill bit 6 at the end stops drilling after reaching the coal seam 2 roof; the structure of the hollow drill rod 4 and the drill bit 6 is as follows: figure 2 shown;

[0021]B. Assembling the hydraulic punching and steam fracturing system: Install the hole sealer 8 at the opening of the piercing hole 7 to seal the inside of the piercing hole 7, and then pass the outlet of the booster pump 15 through the pipeline Pass through the hole sealer 8 and communicate with the hollow drill pipe 4, the inlet of the booster pump 15 communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com