Carbon tank desorption mechanism for motor vehicle

A technology for motor vehicles and carbon tanks, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc. It can solve the problems of difficult control of overall sealing performance, high product cost, and difficult reduction of defective rate, so as to improve product quality and market Competitiveness, overall product cost reduction, and effects of enhanced sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

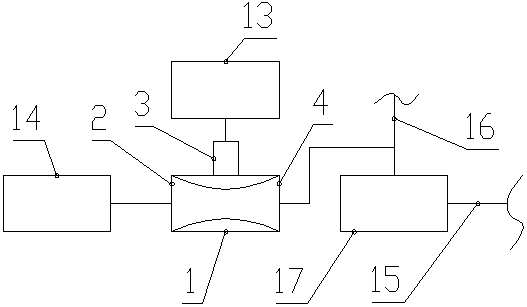

[0021] Such as figure 1 with figure 2 As shown, the motor vehicle carbon canister desorption mechanism of the present invention includes a carbon canister 13, an air filter 17 and an engine supercharger 14 installed in the motor vehicle; the air filter 17 is connected with an intake pipe 15 and an air outlet pipe 16 , The engine supercharger 14 has an intake end and an air outlet end.

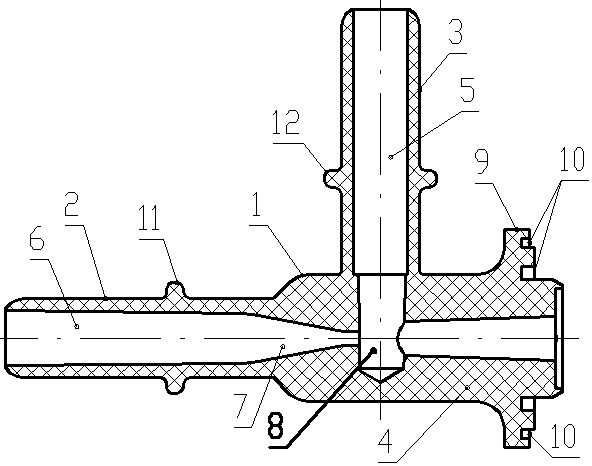

[0022] The motor vehicle carbon tank desorption mechanism of the present invention also includes a Venturi tube, and the Venturi tube includes a housing 1, and the housing 1 includes an intake pipe section 2, a desorption pipe section 3 and a discharge pipe section 4; the intake pipe section of the Venturi tube 2. Connect the gas outlet end of the engine supercharger 14, the discharge pipe section 4 of the Venturi tube is connected to the air outlet pipe 16 of the air filter, and the desorption pipe section 3 of the Venturi tube is connected to the carbon tank 13;

[0023] The inlet pipe sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com