Preparation method of solid adsorption material for biogas decarburizing purification

A solid adsorption material and biogas technology, applied in gaseous fuels, chemical instruments and methods, fuels, etc., can solve the problems of low adsorption capacity and inability to avoid chemical deactivation, and achieve simple preparation methods, high stability, slow down deactivation, etc. live question effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of solid adsorption material applied to biogas decarbonization and purification, including the following steps:

[0030] 1) Pretreatment of NKA-9: Pack NKA-9 in the resin column, wash with deionized water at a flow rate of 2BV / h, 1BV is 1 resin column volume, until the effluent does not have white turbidity; then use 0.2mol / L HNO 3 Soak the solution for 4 hours; then wash with deionized water at a flow rate of 2BV / h until the effluent pH is neutral; dry the washed NKA-9 in an oven at 105°C until the weight no longer changes;

[0031] 2) Weigh 0.8g of BPEI with a molecular weight of 1200Da and dissolve it in 30mL of anhydrous methanol; Weigh 2.0g of pretreated NKA-9, pour it into the BPEI solution, and then add 10mL of anhydrous methanol to rinse the container wall The above NKA-9; the system is magnetically stirred at 350 rpm at 50°C for 5-8 hours, until the solvent is completely evaporated; then the residue is placed in a vacuum drying oven, vacuum dri...

Embodiment 2

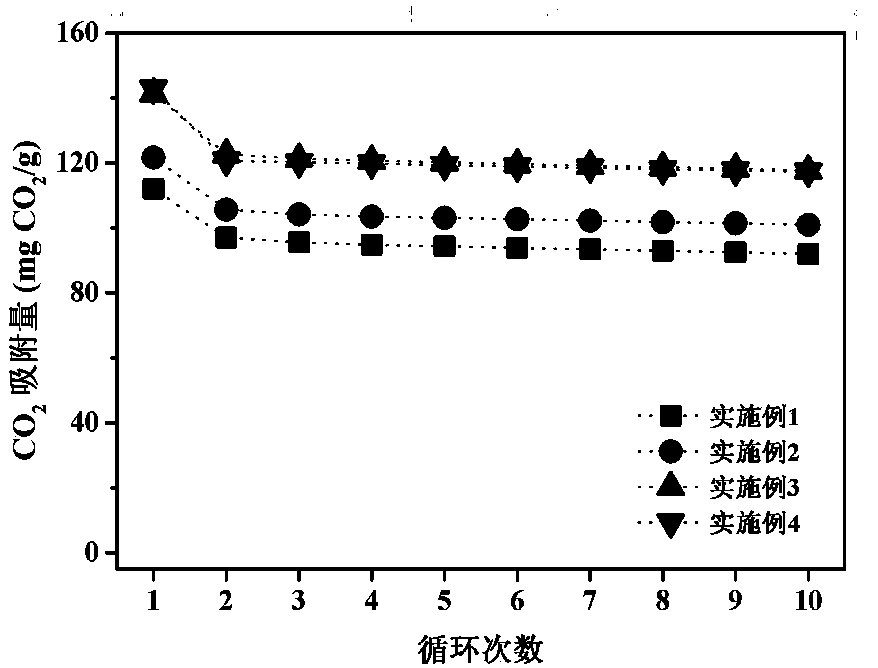

[0040] According to the same preparation method in Example 1, except that the weighed amount of 1200 Da BPEI was changed from 0.8 g to 1.2 g, everything else was the same. A solid adsorption material with a weight ratio of 0.6 between BPEI and NKA-9 was prepared and subjected to ten adsorption-desorption cycle tests.

Embodiment 3

[0042] According to the same preparation method in Example 1, except that the weighed amount of 1200 Da BPEI was changed from 0.8 g to 1.6 g, everything else was the same. A solid adsorption material with a mass ratio of 0.8 of BPEI and NKA-9 was prepared, and the adsorption-desorption cycle test was performed ten times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com