Infrared method for improving coal bed gas extraction rate

A technology for coal seam gas and extraction rate, which is applied in the field of infrared improvement of coal seam gas extraction rate, can solve the problems of complicated construction process, influence safety production, low extraction efficiency, etc. The effect of shortening the extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

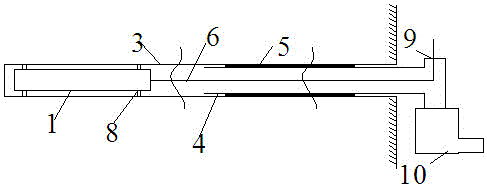

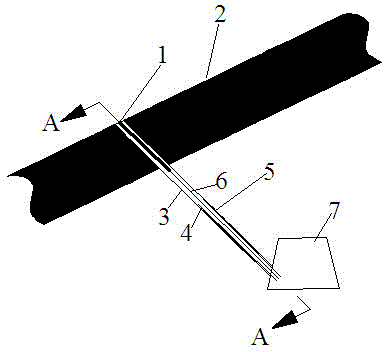

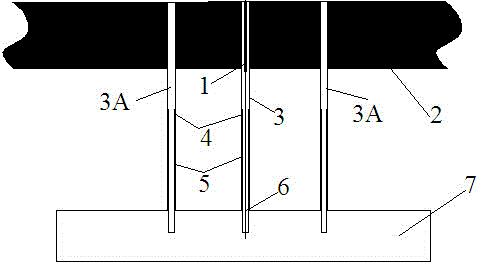

[0017] Depend on Figure 1-Figure 3 A method for improving coal seam gas extraction rate by infrared as shown includes the following steps: (1) measuring the physical and chemical properties of coal seam 2 in the laboratory, using laboratory instruments such as a permeability tester, a specific surface area porosity tester, a heat conduction The coefficient tester and industrial analyzer measure the permeability, porosity, thermal conductivity, water content, etc. of the coal seam 2, and provide experimental basis for the preliminary design of the infrared parameter scheme, and then preliminarily design several sets of infrared parameter schemes. The infrared parameter scheme includes infrared light wave (2) Excavate the bottom extraction roadway 7 along the coal seam 2, that is, excavate the bottom suction roadway 7 along the strike direction under the coal seam 2, and then drill the reconstruction hole 3 from the bottom suction roadway 7 to the coal seam 2, and in the reconst...

Embodiment 2

[0020] Depend on figure 1 , Figure 4 and Figure 5 A method for improving coal seam gas extraction rate by infrared is shown, (1) The physical and chemical properties of the coal seam 2 are measured in the laboratory, using laboratory instruments such as a permeability tester, a specific surface area porosity tester, a thermal conductivity tester and Industrial analyzers, etc. measure the permeability, porosity, thermal conductivity, moisture content, etc. of coal seam 2 to provide experimental basis for the preliminary design of infrared parameter schemes, and then preliminarily design several sets of infrared parameter schemes. The infrared parameter schemes include the frequency and wavelength of infrared light waves , (2) Excavate the top pumping roadway 11 along the coal seam 2, that is, dig out the top pumping roadway 11 along the direction above the coal seam 2, and then drill the reformed hole 3 from the top pumped roadway 11 to the coal seam 2, and make holes on bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com