Non-consumptive type device and method for removing multisource trace harmful gases

A harmful gas, non-consumable technology, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve problems such as difficult control, complex device design, weight, volume, and large power consumption, and achieve composite bed adsorption separation The process is simple, the long-term cycle life is guaranteed, and the effect of reducing volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

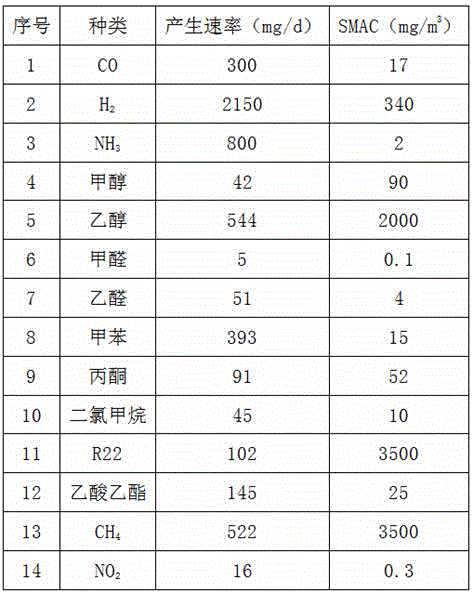

[0049] A multi-source trace toxic and harmful gas removal scheme for a 6-passenger cabin. The design goal is that the device can remove no less than the total amount of pollutants produced in 10 years. The device has a broad-spectrum purification ability for various common volatile organic compounds, of which The generation rate of trace harmful gases is as follows:

[0050] Table 1 Trace harmful gas production rate and concentration control standards

[0051]

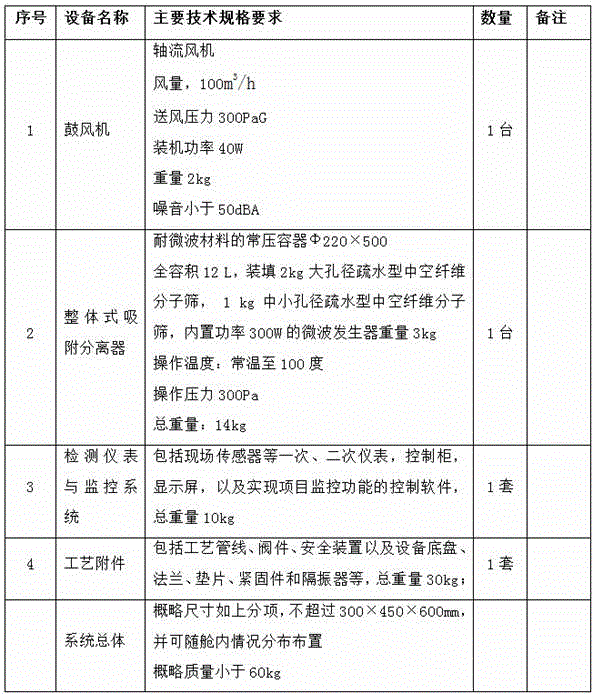

[0052] The device has self-regeneration capability, the power consumption is not more than 350W, the average annual material consumption of all purifiers is not more than 10kg, the initial weight is not more than 90kg, and the device does not cause new harmful gas pollution

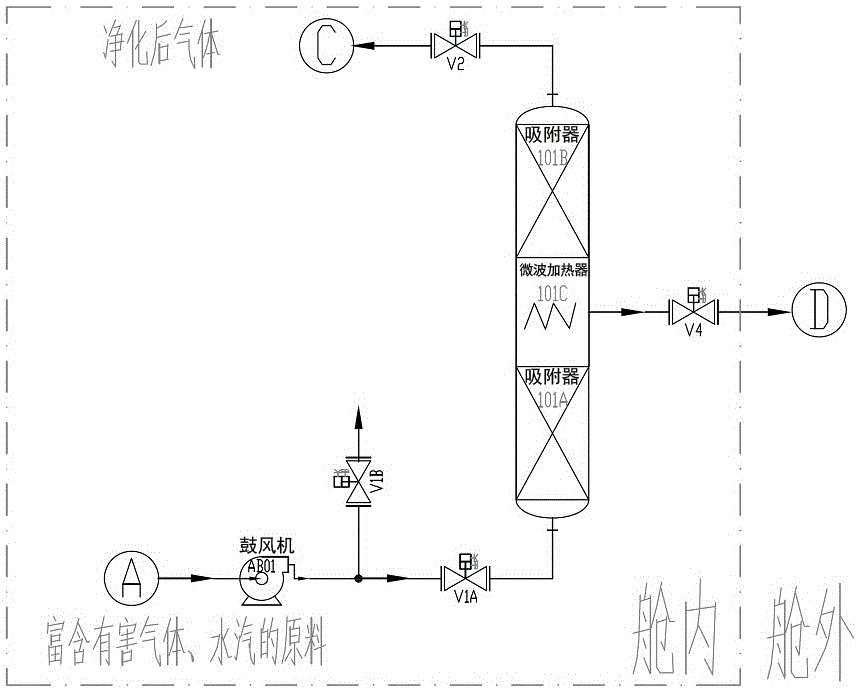

[0053] as attached figure 1 , the system equipment composition design is as follows:

[0054]

[0055] Using the above equipment and figure 1 According to the schematic technical process, the elimination of toxic and harmful gases in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com