Intelligent constant temperature and ultrasonic wave promoting desorption integrated coal sample tank and using method thereof

An ultrasonic, coal sample tank technology, applied in earth-moving drilling, gas discharge, mining equipment and other directions, can solve the problems of cumbersome instruments, waste of manpower and material resources, incomplete gas desorption, etc., to achieve accurate gas content determination, accelerated desorption rate, The effect of saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific embodiments and drawings.

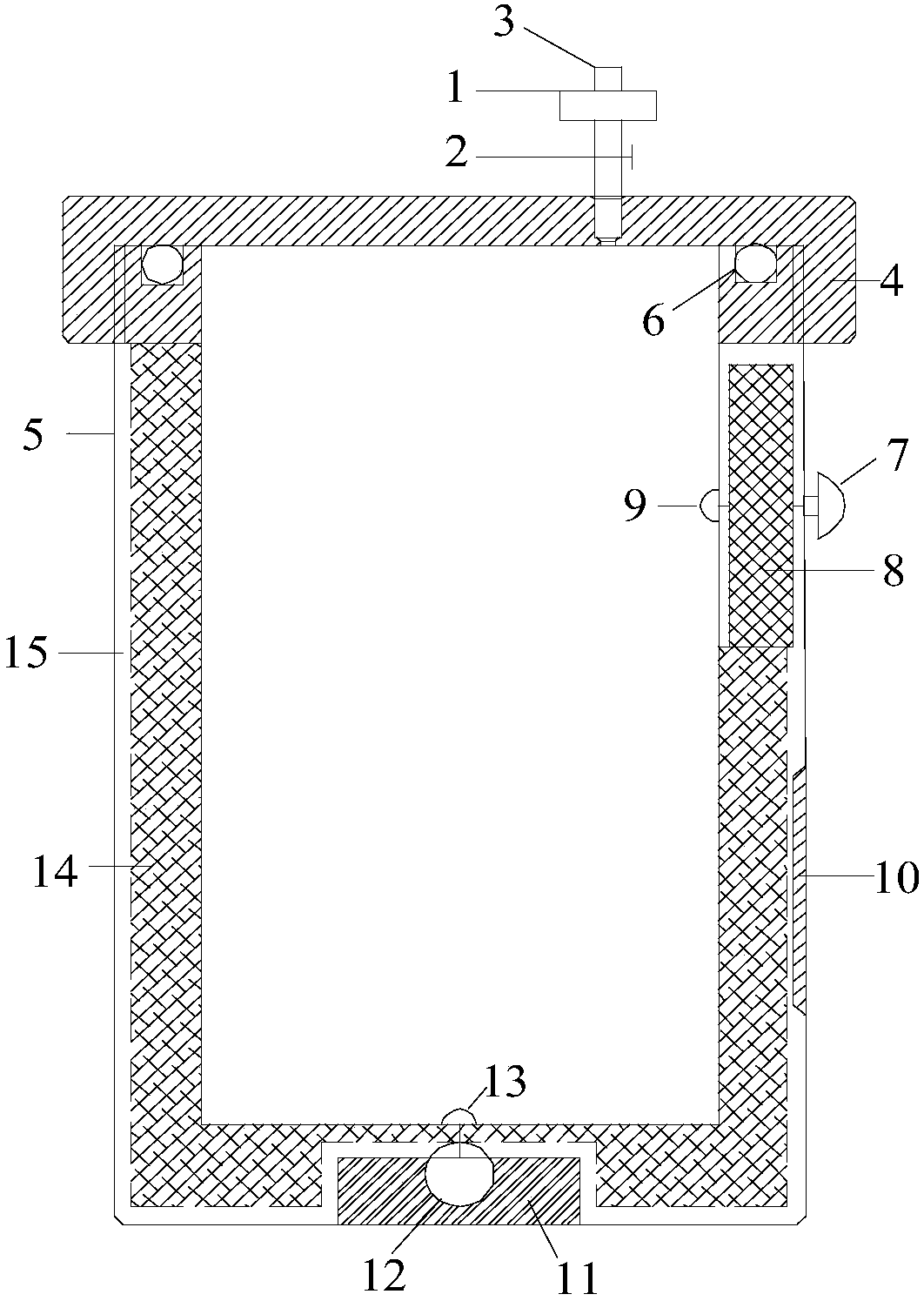

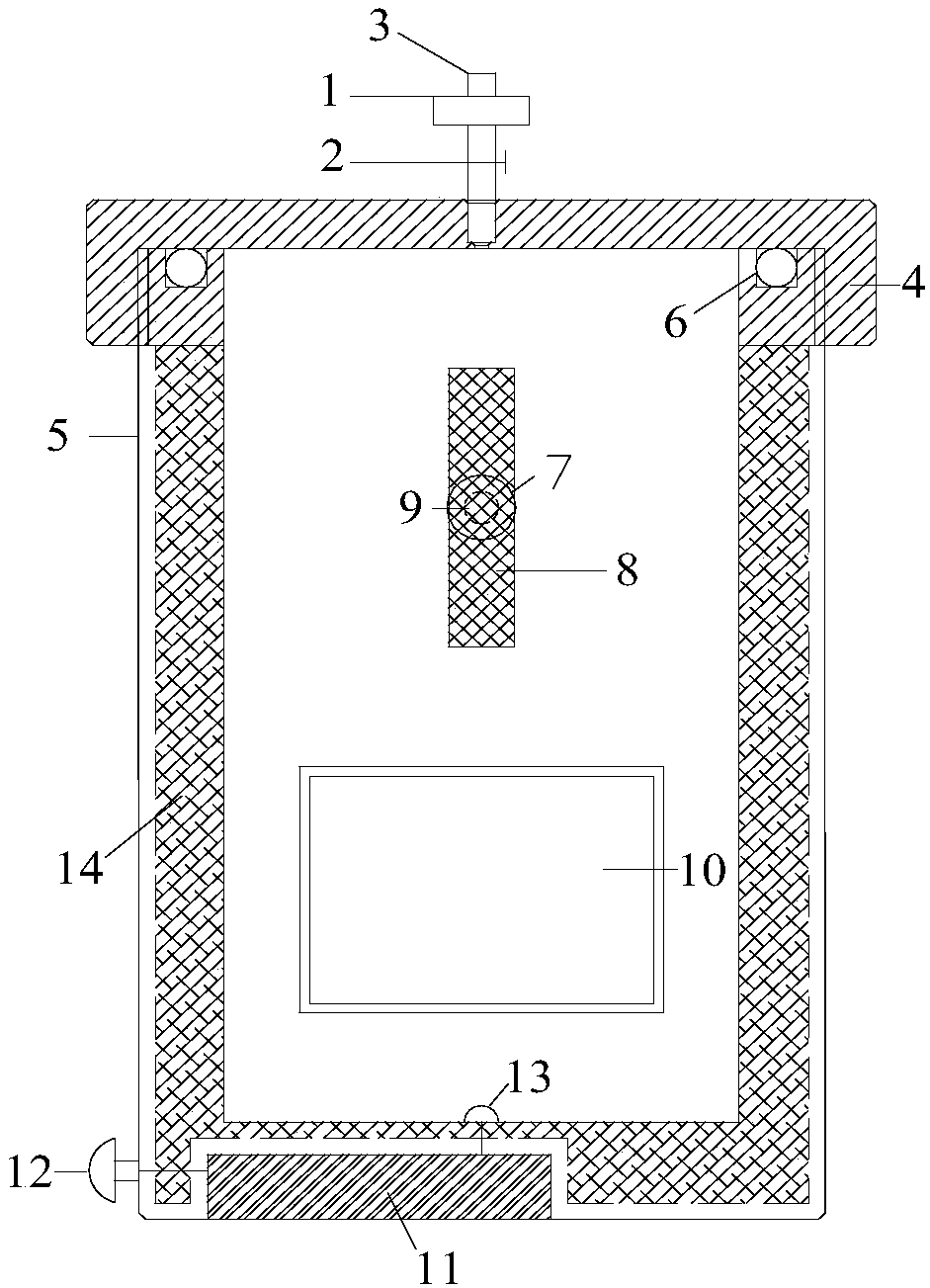

[0025] Such as figure 1 with figure 2 As shown, an intelligent constant temperature, ultrasonic acceleration and desorption integrated coal sample tank includes a tank body 5 and a tank cover 4. The tank cover 4 is screwed on the top of the tank body 5, and is arranged between the tank cover 4 and the tank body 5. The sealing ring 6 seals. An exhaust pipe 3 is installed on the tank cover 4 to communicate with the inside of the tank body 5, and the exhaust pipe 3 is provided with a gas flow meter 1 and an exhaust valve 2. The inner wall of the tank body 5 is provided with a temperature-regulating liner 14, and a temperature-insulating layer 15 made of thermal insulation material is arranged between the temperature-adjusting liner 14 and the inner wall of the tank body 5. A temperature sensor 9 is installed in the tank body 5. An intelligent temperature control de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com