Slotting induced-flow pressure-relief anti-reflection method for complicated seam

A technology of coal seam and induced blowout, which is used in earth-moving drilling, wellbore/well components, mining equipment, etc., can solve the problems of low drilling utilization efficiency, difficult desorption of coal gas, and low gas drainage efficiency. Improve the field application value and social benefits, increase the effective scope of influence, and shorten the coal seam outburst elimination time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

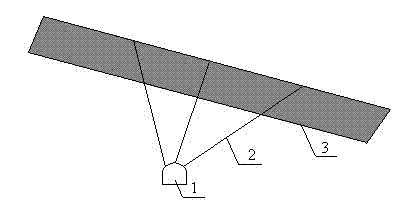

[0019] Embodiment 1. The complex coal seam slotting method of the present invention to induce spouting, pressure relief and anti-permeability enhancement:

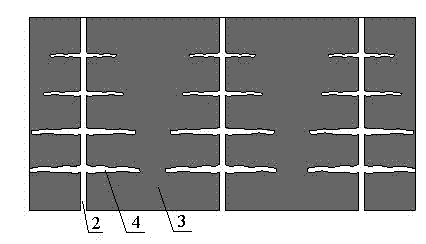

[0020] a. If Figure 4 As shown, firstly, according to the layout of the coal seam bottom drainage roadway and the parameters of the measures to protect the coal seam, the drilling parameters of the through-bed drainage are designed. The distance between the drilling holes 2 entering the coal seam is 4-8m;

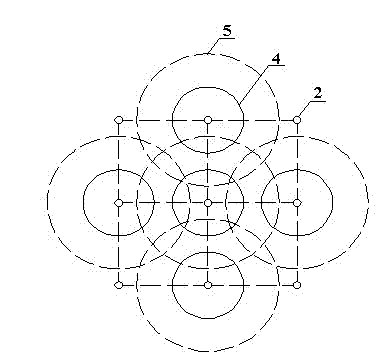

[0021] b. Send the high-pressure water jet into the bed-crossing drainage borehole 2 through the sealed drill pipe to the top plate of the coal seam 3, and start from the coal seam roof of the bed-crossing drainage borehole 2 to perform fixed-point rotary hydraulic slotting through high-pressure water jet rotation, Inducing the unsteady ejection of the coal body, the water pressure of the high-pressure water jet pipeline can be adjusted between 5 and 15 MPa at this time; when the gas gushes violently in the drill hol...

Embodiment 2

[0025] Embodiment two, such as Figure 5 As shown, the method of interlayer drilling and interval slotting to induce jetting to relieve pressure and increase permeability is basically the same as Example 1, except for some similarities. The layout of interlayer-crossing drainage drilling 2 selects the drilling holes for slotting and spraying operations, and selects the number and parameters of slotting and spraying-through-bed drainage drilling 2 according to the actual situation and needs of the site. The distance between the coal seam of drilling hole 2 is 4~6m, and the high-pressure water jet fixed-point cutting and erosion, the amount of coal slag removed and the distance between adjacent cutting positions can be adjusted according to the actual situation of coal seam and gas occurrence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com