A method for filling false roofs without interstitial columns and maintaining the stability of downward single approach filling

An approach filling and stability technology, applied in the fields of filling, underground mining, earthwork drilling, etc., can solve the problems of large loss of ore volume and unrecoverable ore body, so as to reduce the loss of ore, simplify the construction process, reduce the Effect of Ore Loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

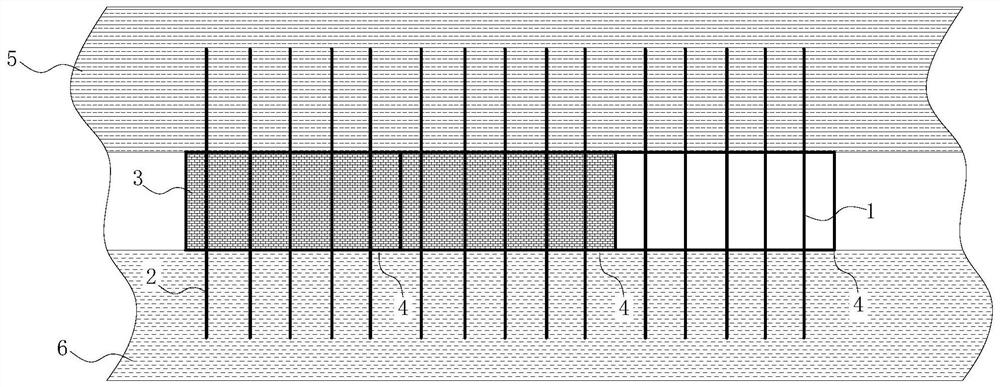

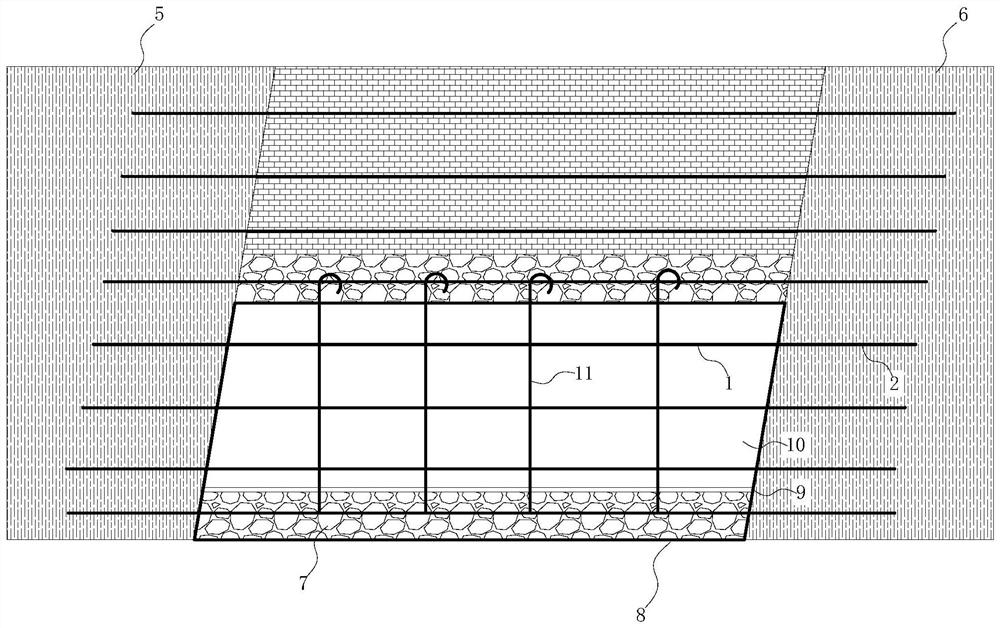

[0029] A method for maintaining the stability of a single downward filling false roof without interstitial columns, the specific steps include:

[0030] Step 1. When mining the inclined thin ore body with broken surrounding rocks, adopt the downward approach layering and non-segmented roadway filling mining method to return to the mining room. After the mining of a mining room in the layering is completed, the artificial field leveling is carried out immediately.

[0031] Before mining, ore chutes, chutes connecting roads, pedestrian ventilation patios, vein-piercing air ducts, vein-piercing transport lanes, cutting drifts and ore loading approaches are all arranged in the footwall of the ore body. The pedestrian ventilation raised shaft is arranged at a distance of 2m from the contact zone of the central footwall of the ore body, and the ore chute and the chute connection road are excavated near the center of the footwall near the ore body; the mining work is carried out from ...

Embodiment 2

[0043] On the basis of Example 1, in order to further illustrate the beneficial effect of a method for filling false roofs without interstitial columns and maintaining the stability of filling a single approach, the actual mining of a gold mine is taken as an example to describe in detail.

[0044] According to geological data and mining technical conditions, the ore body is 150-200m away from the surface, with an average thickness of 5.0m, the average length of the mine house in the stope is 40m, the average length of the mine room column in the adjacent stope is 15m, the height is 50m, and the inclination angle is about 75° , the average ore grade is 3.98g / t, and the ore body itself is extremely broken. The lithology of the ore is pyrite sericite, and the natural collapse phenomenon is serious; the surrounding rock of the ore body is sericized granite, the hanging wall of the ore body is extremely broken, the stability of the foot wall is average, and the thickness is more th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com