Automatic reinjection water heating production increasing process of coal-bed gas well

A coalbed methane well, automatic heating technology, applied in wellbore/well components, mining fluids, earthwork drilling, etc., can solve the problems of difficult to control the combustion front of the burning coal seam, a large amount of coal powder from the coal seam, and limited application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

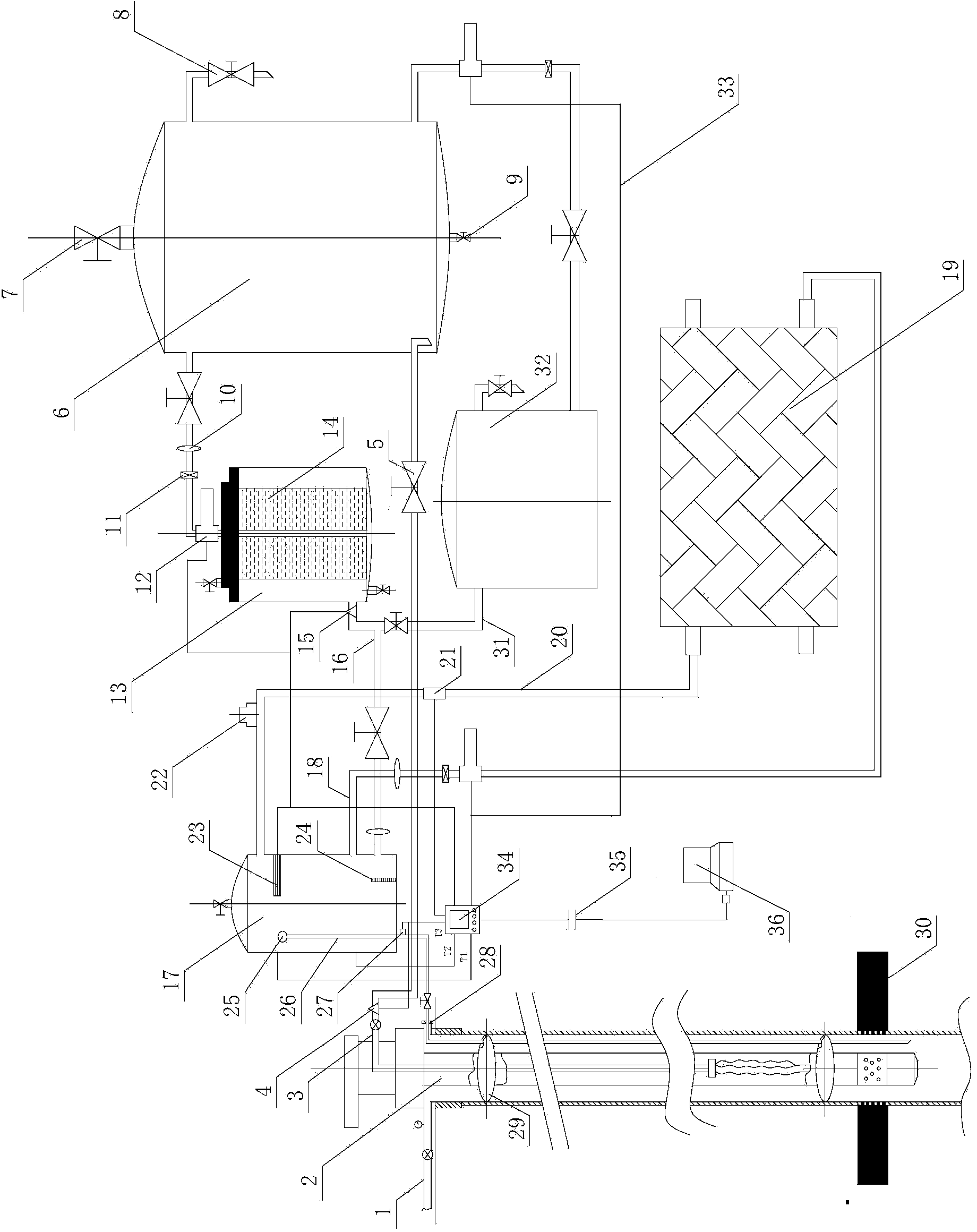

[0022] In order to further understand the invention content, characteristics and effects of this patent, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0023] see figure 1 ,

[0024] An automatic heating and re-injection water stimulation process for coalbed methane wells, comprising the following steps:

[0025] Step A: Precipitate and filter the production fluid, and perform the precipitation and filter one or more times to remove more than 95% of solid particles;

[0026] Step B: After the treatment, the clear liquid is heated by solar energy to make the water temperature reach 60-90°C;

[0027] Step C: hot water is injected into the wellbore through the hot water reinjection pipeline, and the hot water reinjection pipeline extends below the coal seam through the oil casing annulus, raising the temperature of the original wellbore liquid by more than 20°C;

[0028] Step D: Repeat the above steps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com