Antibacterial microcapsule capable of controllably releasing cinnamyl aldehyde and preparation method thereof

A technology of cinnamaldehyde and microcapsules, which is applied in the fields of food, medicine and chemical industry, can solve the problems of cumbersome steps, loss of cinnamaldehyde, high equipment cost, etc., and achieve the effects of simple preparation process, prolonged release time and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

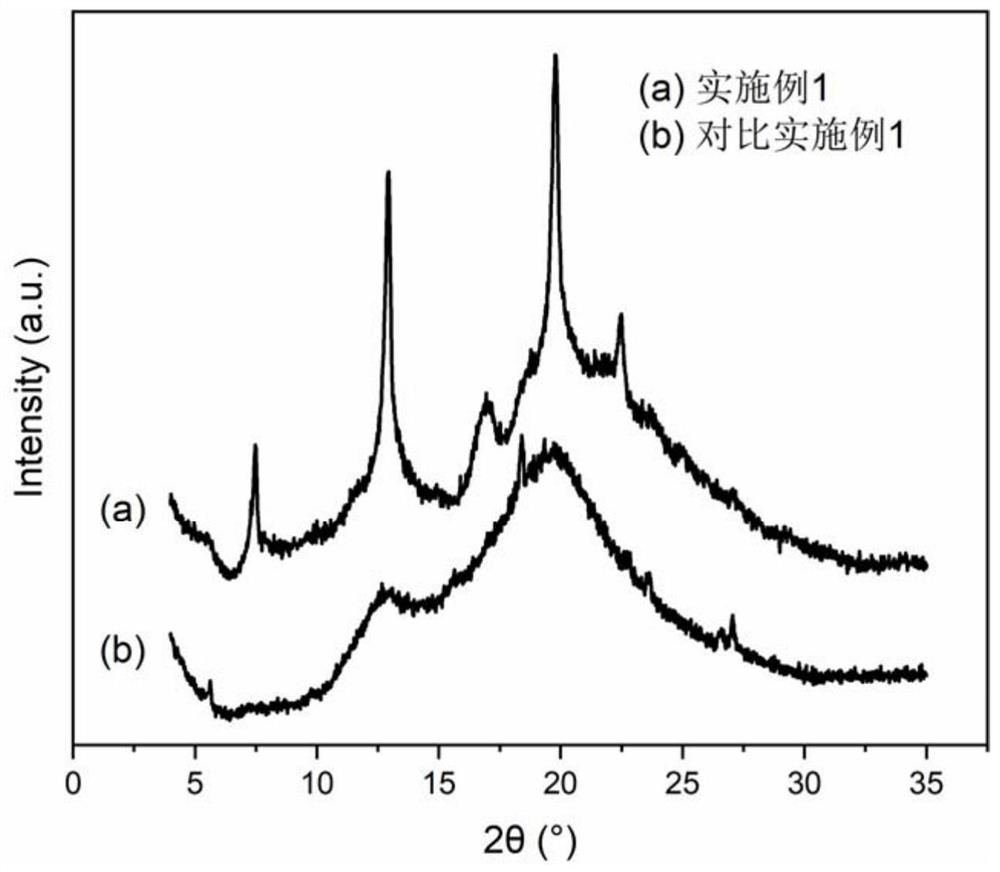

Embodiment 1

[0063] (1) Preparation of hollow V-starch

[0064] 10 g of starch was dispersed in 70 g of ethanol aqueous solution (40%, w / w), and 50 g of 3M NaOH solution was added dropwise at a speed of 4 g / min. After stirring for 30 min, slowly add 20 g of ethanol aqueous solution (40%, w / w) to the starch milk dropwise at room temperature, and centrifuge at 8000 g for 10 min;

[0065] The obtained precipitate was washed twice with ethanol aqueous solution (40%, w / w) and dispersed, neutralized with 3M ethanolic hydrochloric acid solution, centrifuged, and then washed with ethanol aqueous solution (80%, w / w) and absolute ethanol respectively. After each washing once, the obtained starch was dried in an oven at 40°C, pulverized and sieved to obtain hollow V-shaped starch;

[0066] (2) Preparation of antibacterial microcapsules by embedding cinnamaldehyde in hollow V-starch

[0067] 2 g of hollow V-starch was dispersed in absolute ethanol containing 2 g of cinnamaldehyde, and then 16 g of d...

Embodiment 2

[0072] (1) Preparation of hollow V-starch

[0073] 10 g of starch was dispersed in 70 g of ethanol aqueous solution (40%, w / w), and 50 g of 3M NaOH solution was added dropwise at a speed of 4 g / min. After stirring for 30 min, slowly add 20 g of ethanol aqueous solution (40%, w / w) to the starch milk dropwise at room temperature, and centrifuge at 8000 g for 10 min;

[0074] The obtained precipitate was washed twice with ethanol aqueous solution (40%, w / w) and dispersed, neutralized with 3M ethanolic hydrochloric acid solution, centrifuged, and then washed with ethanol aqueous solution (80%, w / w) and absolute ethanol respectively. After each washing once, the obtained starch was dried in an oven at 40°C, pulverized and sieved to obtain hollow V-shaped starch;

[0075] (2) Preparation of antibacterial microcapsules by embedding cinnamaldehyde in hollow V-starch

[0076] 2 g of hollow V-starch was dispersed in absolute ethanol containing 2 g of cinnamaldehyde, and then 20 g of d...

Embodiment 3

[0079] (1) Preparation of hollow V-starch

[0080] 10 g of starch was dispersed in 70 g of ethanol aqueous solution (40%, w / w), and 50 g of 3M NaOH solution was added dropwise at a speed of 4 g / min. After stirring for 30 min, slowly add 20 g of ethanol aqueous solution (40%, w / w) to the starch milk dropwise at room temperature, and centrifuge at 8000 g for 10 min;

[0081] The obtained precipitate was washed twice with ethanol aqueous solution (40%, w / w) and dispersed, neutralized with 3M ethanolic hydrochloric acid solution, centrifuged, and then washed with ethanol aqueous solution (80%, w / w) and absolute ethanol respectively. After each washing once, the obtained starch was dried in an oven at 40°C, pulverized and sieved to obtain hollow V-shaped starch;

[0082] (2) Preparation of antibacterial microcapsules by embedding cinnamaldehyde in hollow V-starch

[0083] 2 g of hollow V-starch was dispersed in absolute ethanol containing 2 g of cinnamaldehyde, and then 12 g of d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com